Automatic choke system for carburetor

A technology for choke valves and carburetors, which is applied in the direction of carburetors, charging systems, machines/engines, etc., can solve problems such as speed reduction, and achieve the effects of preventing excessive thermal degradation, avoiding increase, and stable warm-up operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

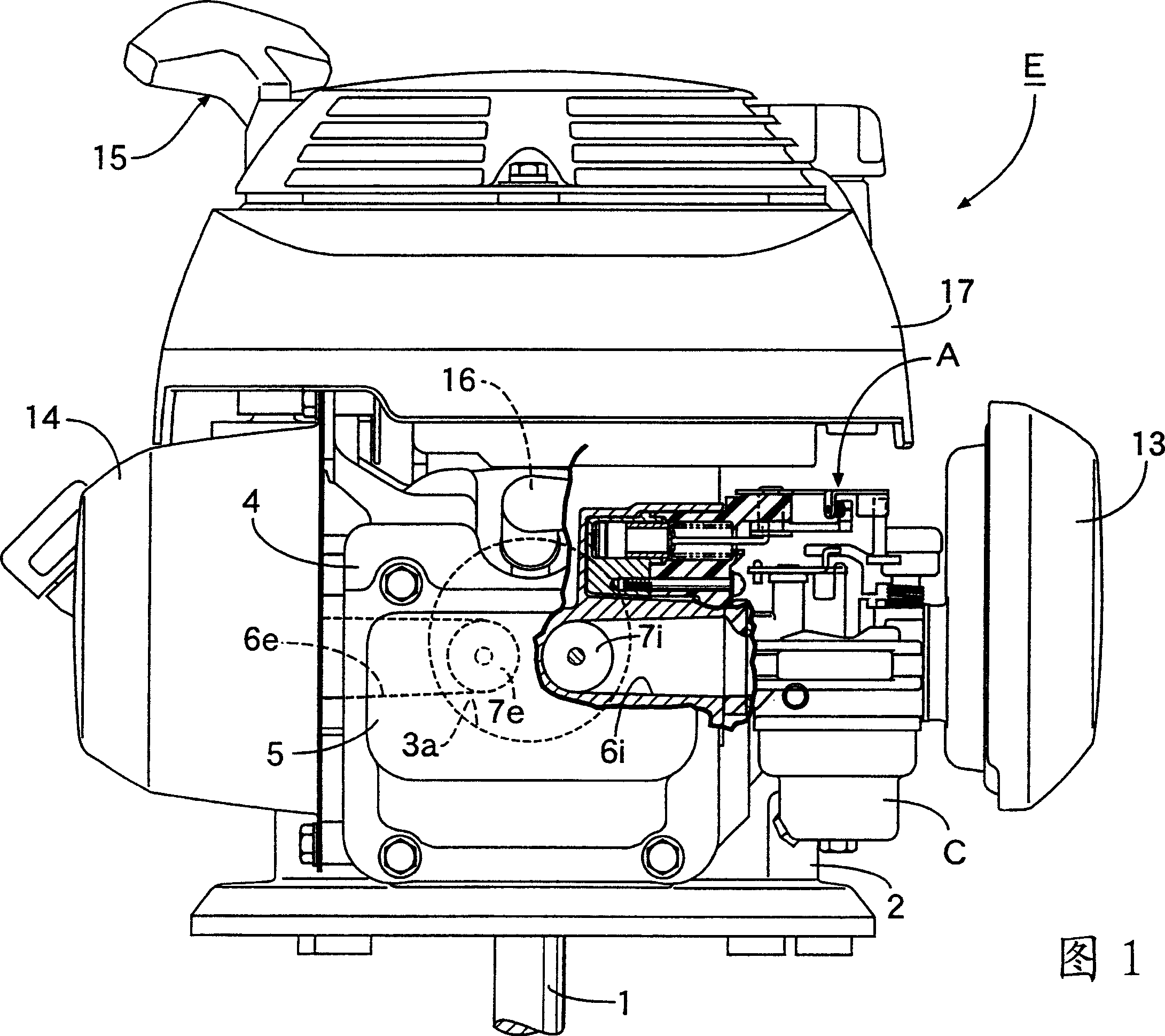

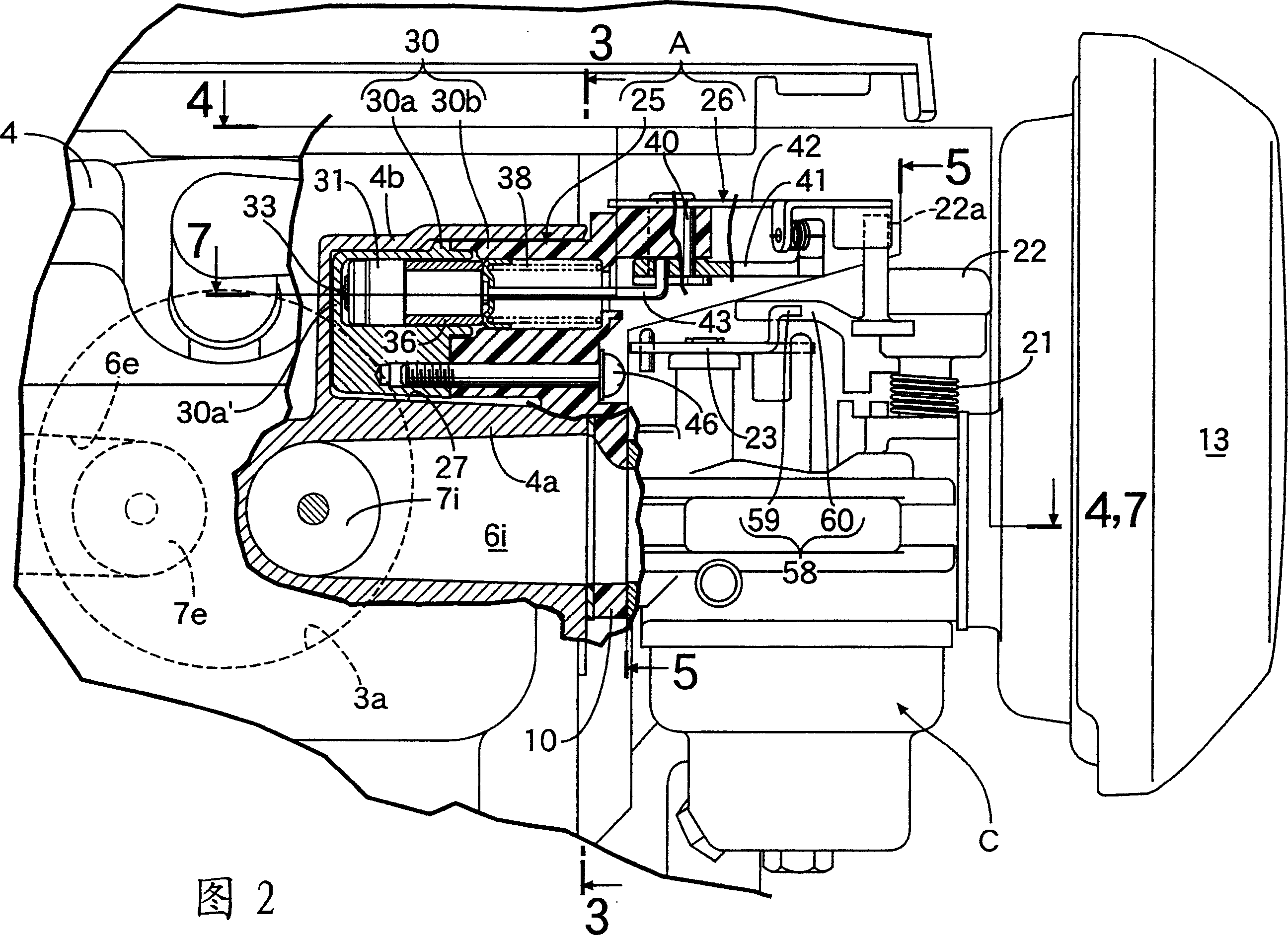

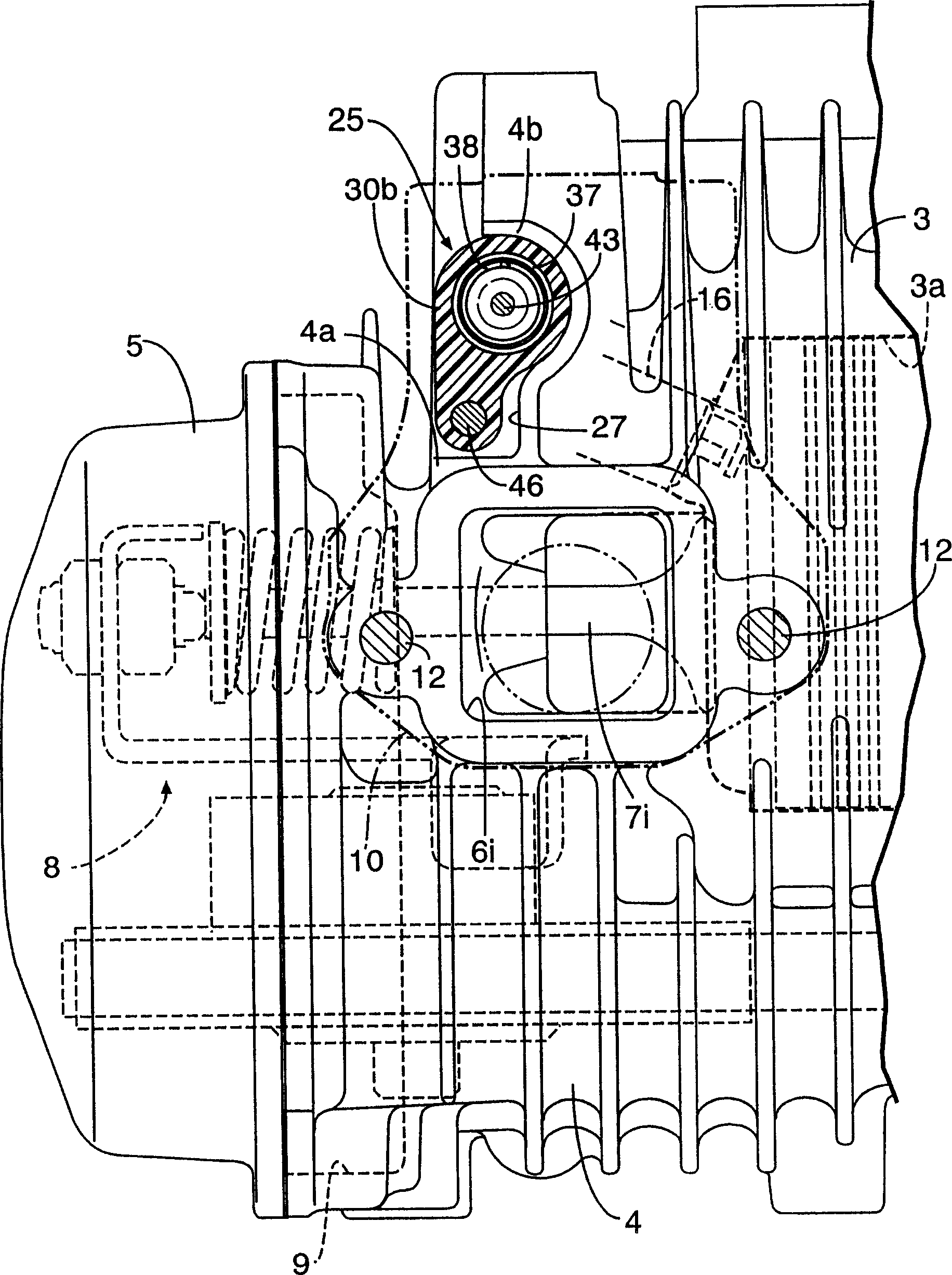

[0046] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

[0047] In Figure 1 to image 3 In , reference letter E denotes a four-stroke engine used as a power source for various working machines. The engine E includes: a crankcase 2 vertically supporting a crankshaft 1; a cylinder block 3 extending horizontally from the crankcase 2 and having a cylinder bore 3a; Provided in the cylinder head 4 are: an intake port 6i and an exhaust port 6e, which are opened and closed by the intake valve 7i and the exhaust valve 7e, respectively; and the valve train 8 of the exhaust valve 7e. A cover 5 for closing the valve operating chamber 9 is joined to the end face of the cylinder head 4 .

[0048] The outer ends of the intake port 6i and the exhaust port 6e are opened on one side and the opposite side of the cylinder head 4, respectively. A carburetor C having an intake path 11 communicating with the intake port 6i is joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com