Family-size updraught tar-free biomass gasification direct burn type furnace

A direct-fired furnace, tar-free technology, applied in household furnaces/stoves, gaseous heating fuel, applications, etc., can solve problems such as increased operating costs, cumbersome and complicated operation processes, and cannot fundamentally solve the problem of tar, so as to improve gas The effects of temperature, structure improvement, and good gasification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

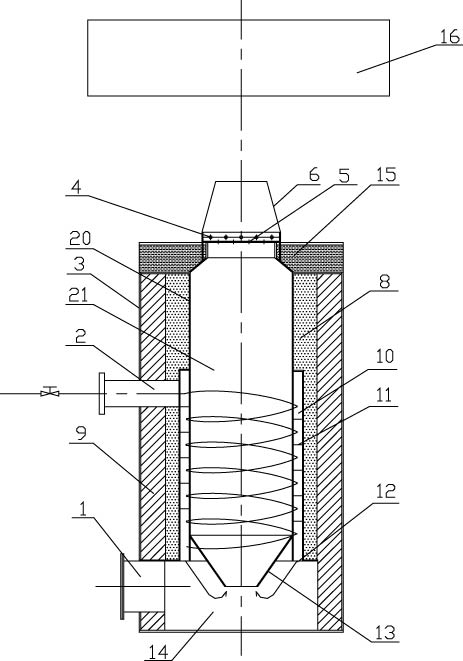

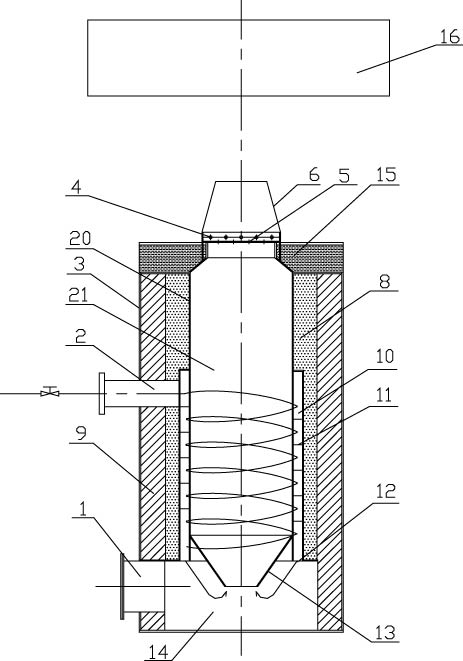

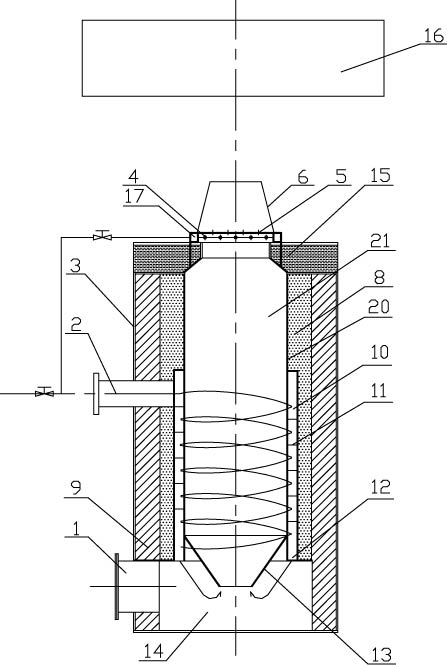

[0007] Specific embodiment 1: In conjunction with Fig. 1, Fig. 3 and Fig. 4, the household updraft-type tar-free biomass gasification direct combustion furnace of this embodiment includes ash cleaning door 1, air pipe 2, furnace body, and refractory layer 8 , insulation layer 9, annular water tank 15, spiral partition 11 and ash hopper 13; body of furnace is made of inner furnace drum 20 and outer furnace drum 3, and the cavity between inner furnace drum 20 and outer furnace drum 3 is from inside to A refractory layer 8 and an insulating layer 9 are arranged in sequence on the outside, the upper end faces of the refractory layer 8, the insulating layer 9 and the furnace body are flush, the lower end faces of the refractory layer 8 and the inner furnace barrel 20 are flush, and the annular water tank 15 is set On the upper end face of the furnace body, the lower end face of the refractory layer 8 is located above the lower end face of the insulation layer 9, and the inner cavity...

specific Embodiment approach 2

[0008] Specific Embodiment 2: In conjunction with FIG. 1 and FIG. 4 , the cross section of the gas stove 6 in this embodiment is circular, and a plurality of secondary air inlet holes 4 are evenly distributed along the circumferential direction of the side wall of the gas stove 6 . With such arrangement, the secondary air through the secondary air inlet hole 4 is evenly sent to the bottom of the gas stove 6 to mix with the gas. Others are the same as the first embodiment.

specific Embodiment approach 3

[0009] Specific Embodiment 3: Referring to FIG. 4 , a plurality of gas outlet holes 5 in this embodiment are evenly distributed along the circumferential direction of the bottom end surface of the gas stove 6 . Such setting can play a role in stabilizing combustion. Others are the same as the second embodiment.

[0010] Embodiment 4: In conjunction with Fig. 3 and Fig. 5, the difference between this embodiment and Embodiment 1 is that a layer of combustion-stabilizing layer 18 is fixed inside the gas stove 6 of this embodiment, and the combustion-stabilizing layer 18 adopts heat-resistant Woven from silk. Such setting has the effect of stable combustion and burnout.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com