Down-draught type biomass gasifier for secondarily cracking tar

A secondary cracking and gasifier technology, which is applied in the petroleum industry and the manufacture of combustible gas, etc., can solve the problems of affecting the stable operation of the gasifier, high tar content, blockage of pipes, etc., and achieve good gasification effect and reduce smoke and dust content. , the effect of the high position of the gas outlet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

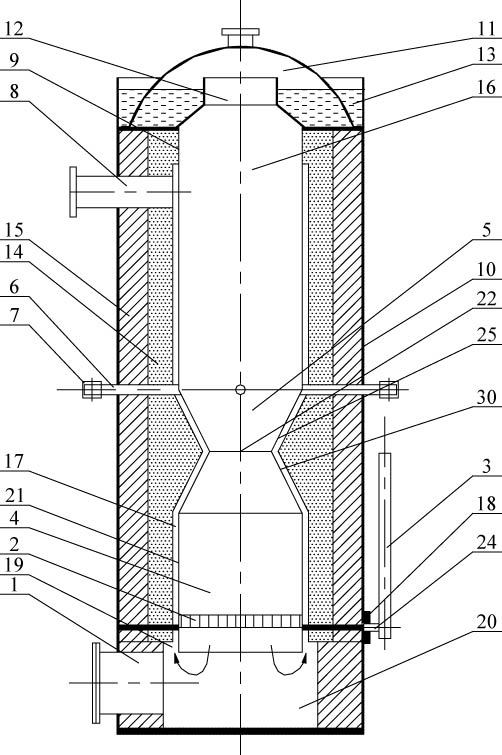

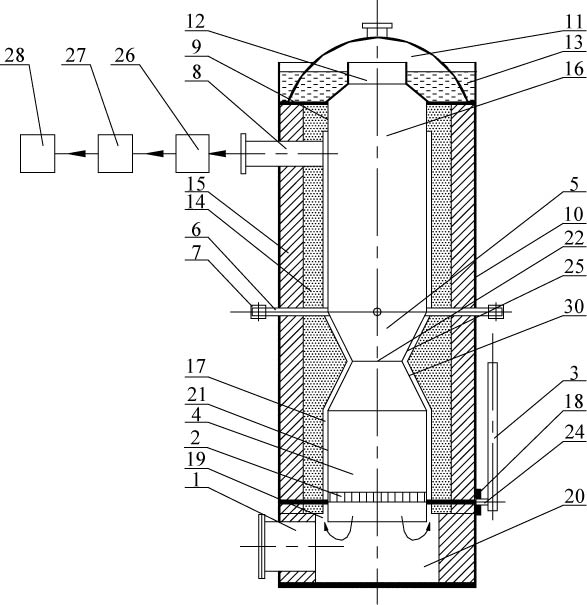

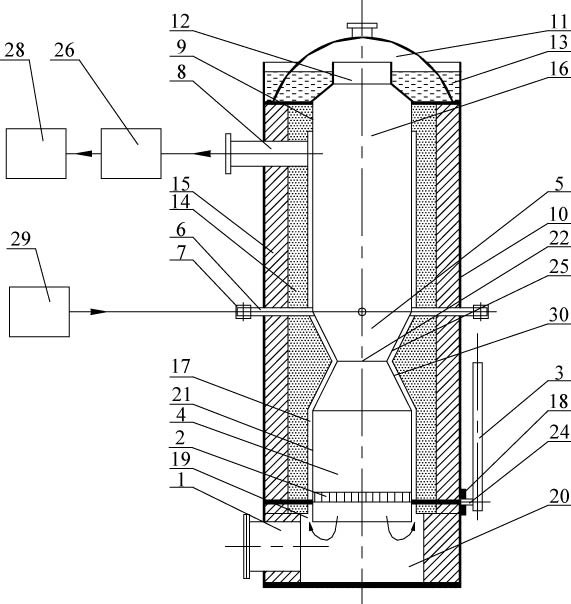

[0007] Specific implementation mode one: combine figure 1 and Figure 4-Figure 6 Explain that the downdraft tar secondary cracking biomass gasification furnace in this embodiment includes ash cleaning door 1, movable grate assembly 2, multiple intake pipes 6, plugging 7, gas outlet pipe 8, inner furnace cylinder, outer Furnace tube 10, furnace cover 11, refractory layer 14 and insulation layer 15; the inner furnace tube is arranged in the outer furnace tube 10, the lower end of the outer furnace tube 10 is closed, the outer furnace tube 10 is a cylindrical tube, and the inner cavity of the inner furnace tube is The furnace, the inner furnace tube is composed of an upper cylindrical tube 9, an upper truncated tube 25, a lower truncated tube 30 and a lower cylindrical tube 21 from top to bottom, and the small diameter of the upper truncated tube 25 and the lower truncated tube 30 The end faces are butted to form a furnace necking 22, the lower end face of the upper cylindrical ...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 with Image 6 Description, the movable grate assembly of the present embodiment is made up of movable grate 2, grate rocker 3, sealing ring 18 and grate rocker shaft 24; The side wall of side wall, insulation layer 15, refractory layer 14 and inner furnace cylinder is fixedly connected with movable fire grate 2, and the other end of fire grate rocker shaft 24 is fixed with an end of fire grate rocker 3 that is arranged on the outside of outer furnace cylinder 10. Then, the grate rocker shaft 24 is vertically arranged with the grate rocker 3 , and the sealing ring 18 is mounted on the grate rocker shaft 24 and leans against the outer wall of the outer furnace tube 10 . In this way, the grate rocker shaft 24 is sealed with the outer furnace cylinder through the sealing ring 18; the grate is moved by rotating the grate rocker 3, and then the purpose of removing ash on the grate is realized. Others are the same as the...

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 Note, the difference between this embodiment and specific embodiment 1 or 2 is that: the gasifier in this embodiment also includes an annular water tank 13; 13, the cross section of furnace cover 11 is circular. With such setting, the furnace cover can be water-sealed and has a good sealing effect. Moreover, the circular furnace cover can also condense and collect the water vapor evaporated by the biomass into the sealed annular water tank, so there is no high requirement for the moisture content of the biomass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com