Metal precursor solutions for chemical vapor deposition

A technology of chemical vapor deposition and precursor solution, which is applied in organic chemistry, gaseous chemical plating, metal material coating technology, etc., and can solve problems such as inappropriate stoichiometric ratio of deposited film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Prepare 1.0M solution of titanium isopropoxide in N-methyl-2-pyrrolidone

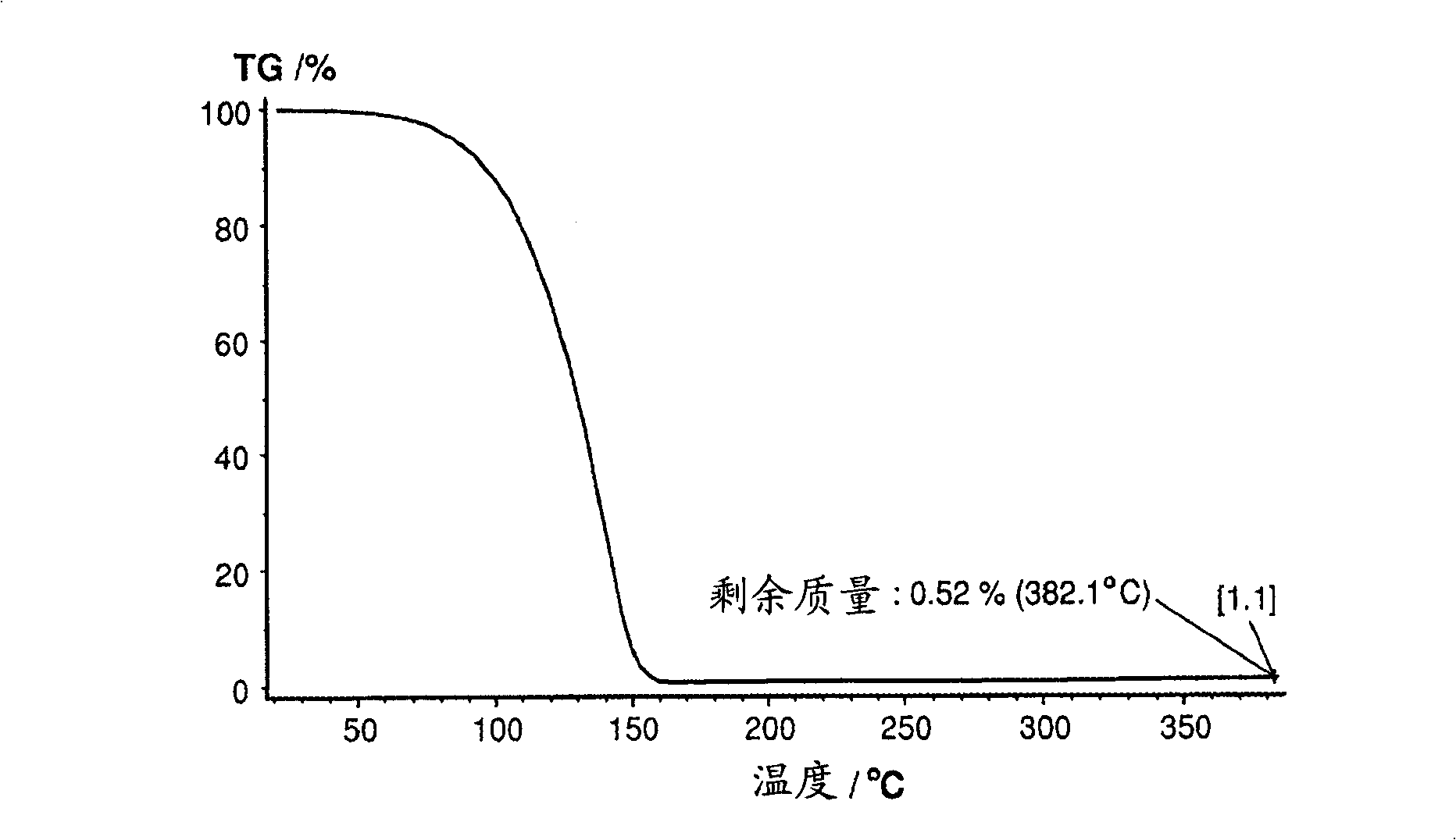

[0068] In a 2 mL vial, a pale orange solution of titanium isopropoxide (0.10 g, 0.35 mmol) and 0.35 mL of N-methyl-2-pyrrolidone (NMP) was prepared. The solution was kept at room temperature overnight and did not show any noticeable changes. figure 1 is the TGA of a 1.M solution of titanium isopropoxide in N-methyl-2-pyrrolidone, which suggests a smooth gasification process in the temperature range of 20-400°C. This vaporization behavior suggests that this solution can be applied to chemical vapor deposition or atomic vapor deposition by bubbling or direct liquid injection.

Embodiment 2

[0070] Prepare 0.1M tris(2,2,6,6-tetramethyl-3,5-heptanedionylated)lanthanum in N-methyl-2-pyrrolidone

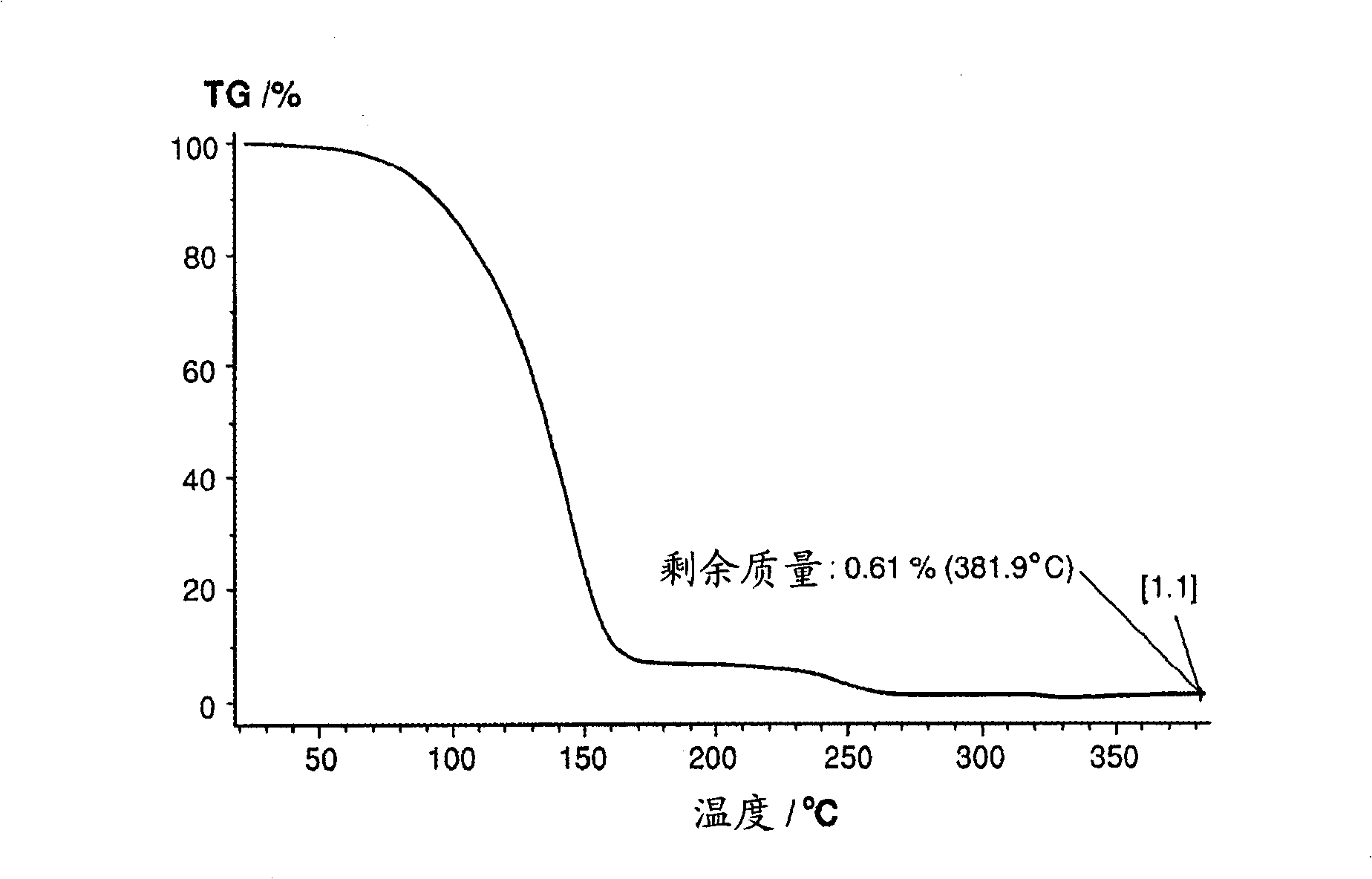

[0071] In a 2mL vial, prepare La(thd) 3 (0.05 g, 0.07 mmol) and 0.78 mL of a clear solution of NMP. figure 2 is the TGA of a 0.1M solution of tris(2,2,6,6-tetramethyl-3,5-heptanedionylated)lanthanum in N-methyl-2-pyrrolidone, which shows that there are two gasification processes , the first is mainly of NMP and the second is of tris(2,2,6,6-tetramethyl-3,5-heptanedionylated)lanthanum. This vaporization behavior indicates that this solution can only be used for chemical vapor deposition or atomic vapor deposition by direct liquid injection.

Embodiment 3

[0073] Preparation of tetra(ethylmethylamino)zirconium solution in N-methyl-2-pyrrolidone

[0074] Three NMP solutions of tetrakis(ethylmethylamino)zirconium (TEMAZ) were prepared according to Table 1. Both are clear yellow solutions.

[0075] Table 1

[0076] sample

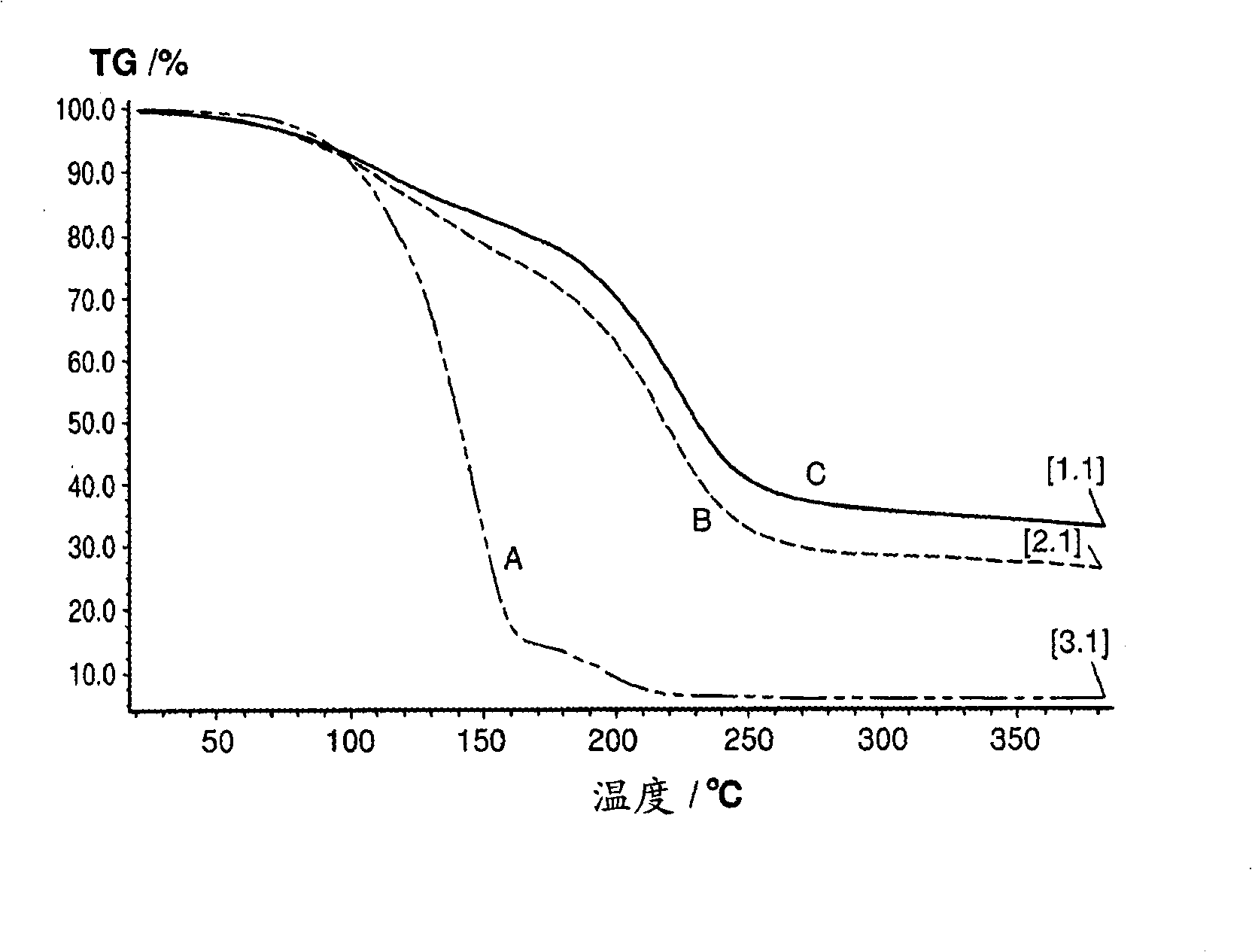

[0077] image 3 TGA graphs of the solutions are shown, suggesting that direct liquid injection with lower concentrations is preferred.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com