Clean coal burning catalyst

A medium and clean technology, applied in the field of coal-fired or clean coal additives and their production processes, can solve the problems of unavailability of inferior coal, environmental impact of pollutants, incessant combustion of high-quality coal, etc., so as to reduce coal consumption and price. Low cost, lower fuel cost and operating cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

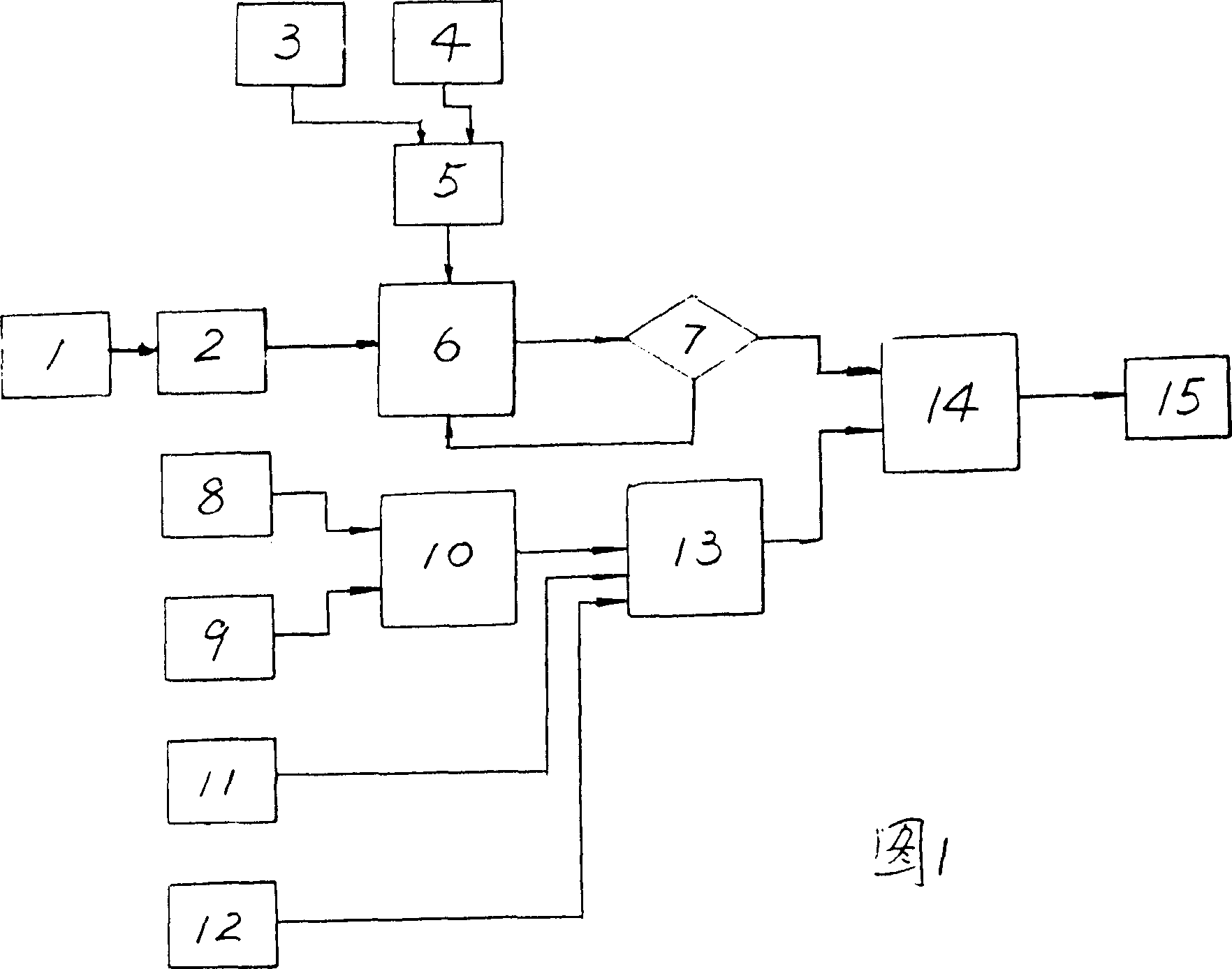

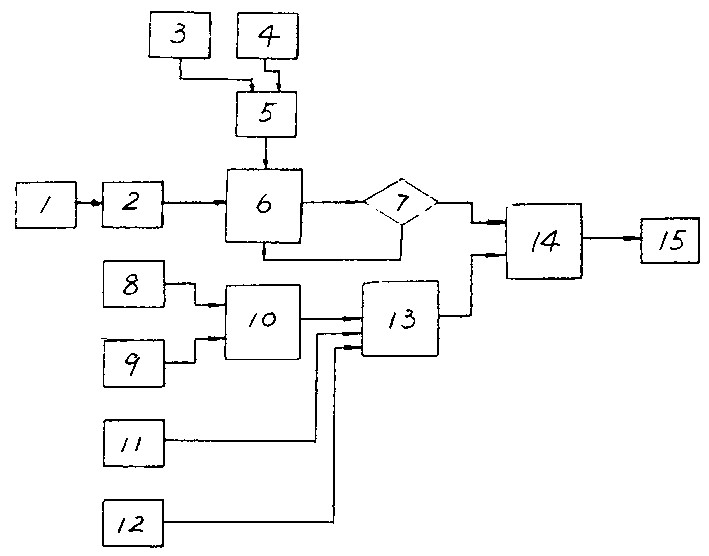

Image

Examples

Embodiment

[0021] Embodiment: prepare the clean coal catalyst medium of the present invention according to the following formula (percentage by weight) and the described production process:

[0022] Sodium chloride 57.2, magnesium chloride 25, manganese borate 3, potassium permanganate 3.8, potassium chlorate 5, copper iron titanium compound 3, additive 3.

[0023] The method of use is as follows: add 0.3% of coal per ton of coal and dissolve in 10 times of water, and then mix and stir with coal.

[0024] According to comparative measurements by authoritative departments, under the condition of a 4t steam boiler, the calorific value of coal increases by 1200-1600 kcal / kg, which provides conditions for the large-scale use of low-quality coal with a calorific value of 1500-4000 kcal / kg; When it is 77%, the coal saving rate is still > 20%; the furnace temperature can be increased by 50-100°C; the carbon content of cinder can be reduced to about 5%, and the discharge of cinder can be reduced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com