Gasification burner

An oxidant channel and inner tube technology, which is applied in the gasification process, gasification device details, gasification device mechanical details, etc. Problems with low conversion rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

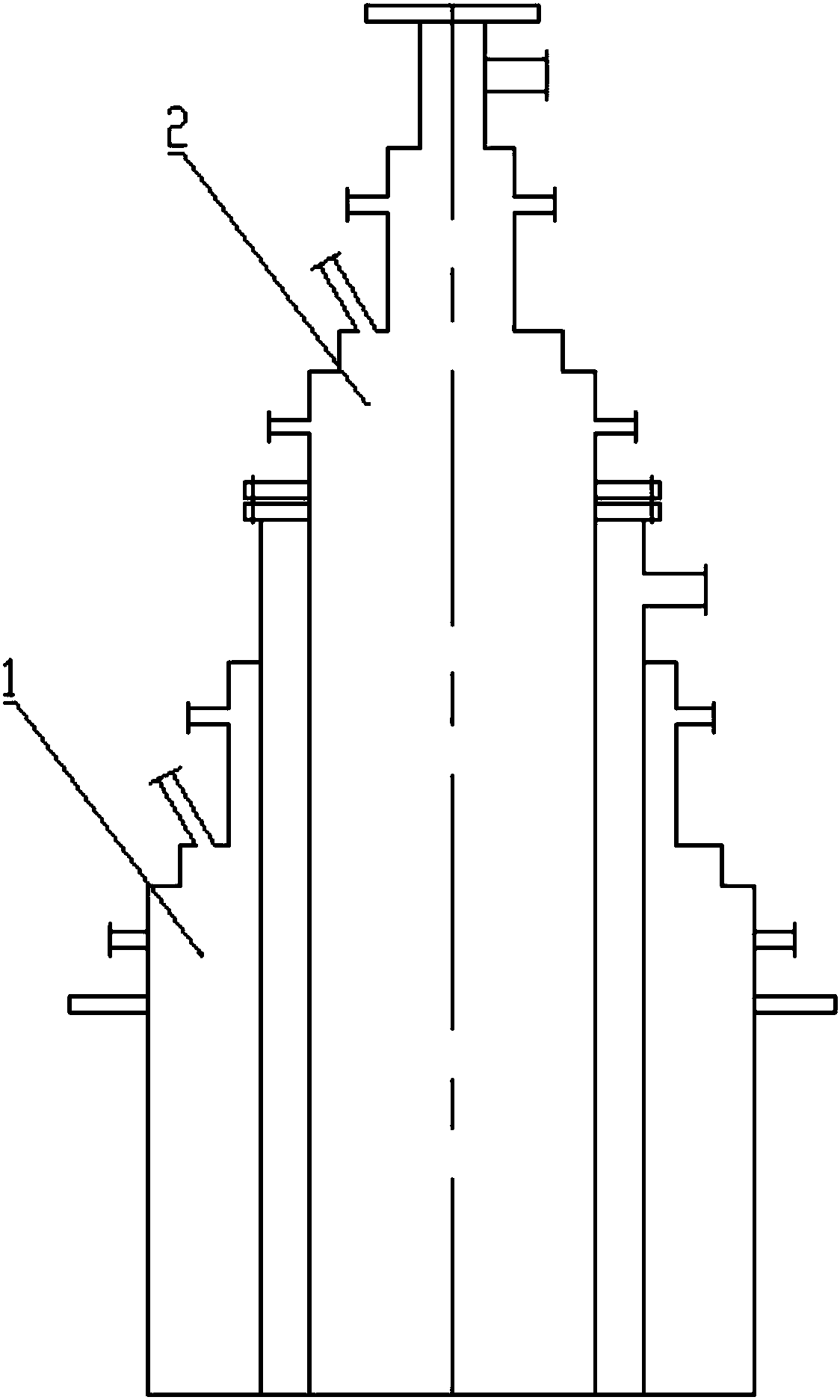

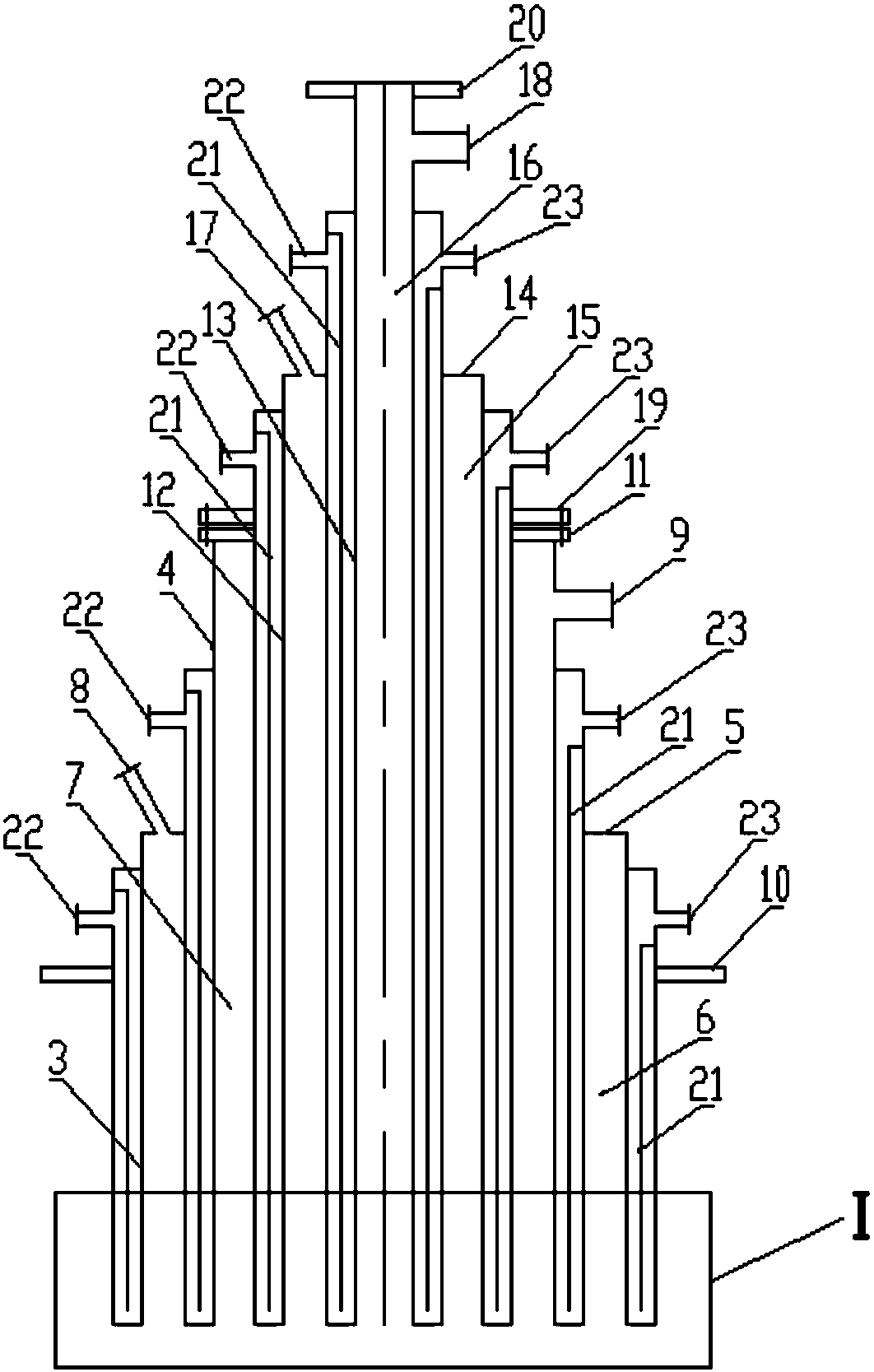

[0030] A gasification burner, such as Figure 1 to Figure 3 As shown, including the main burner 1, the inner side of the main burner 1 is provided with N-level sub-burners 2, N is an integer greater than or equal to 1, and the main burner 1 and each sub-burner 2 have independent fuel channels and oxidant channels; the main burner 1 and the sub-burners 2 of each level are arranged in a coaxial coaxial structure from outside to inside, the inner diameter of the main burner 1 is larger than the outer diameter of the first-stage sub-burner 2, The inner diameters of the burners 2 are larger than the outer diameters of the next-stage burners 2 .

[0031] It should be noted, figure 1Shown is a combined gasification burner composed of a main burner 1 and a sub-burner 2, that is, the number of sub-burners 2 is N=1.

[0032] It can be seen that in the gasification burner of this embodiment, the fuel and oxidant ejected by it can be increased by increasing the fuel passage and the oxid...

Embodiment 2

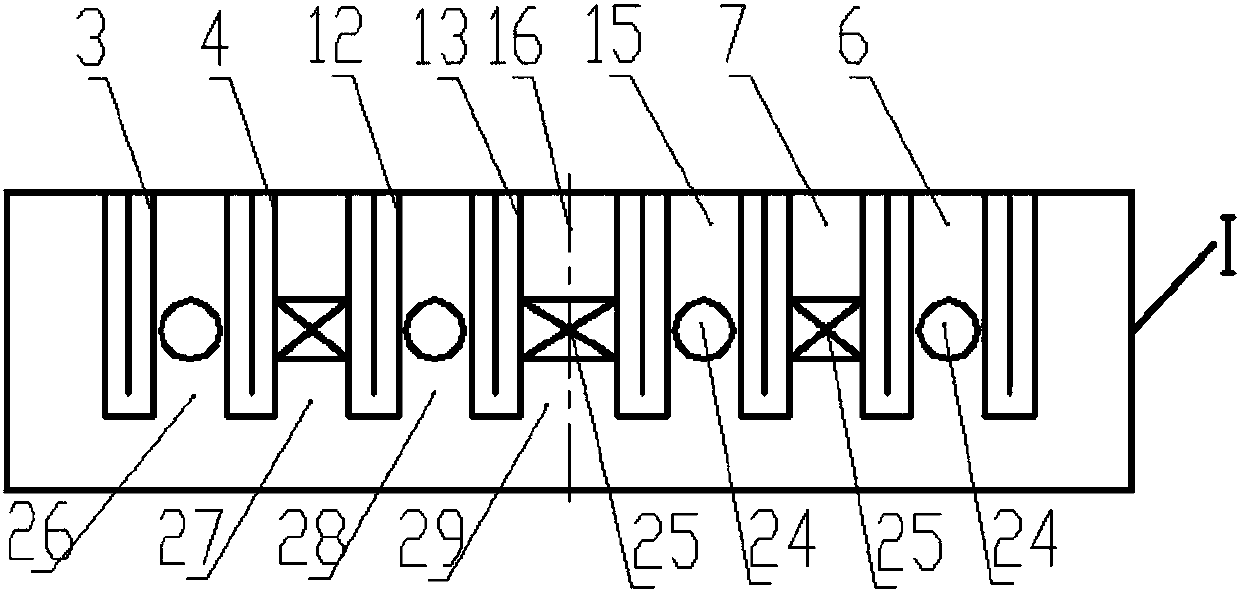

[0034] A gasification burner, similar to Embodiment 1, the difference is that the female burner 1 includes a female outer tube 3 and a female inner tube 4 coaxially arranged from outside to inside, and a female outer tube 3 and a female inner tube 4 Connected through the female cover plate 5; the female outer pipe 3 and the female inner pipe 4 are stainless steel pipes or nickel-based alloy pipes with a certain thickness, which can withstand the pressure of fuel or oxidant in contact with the inner and outer pipe walls; the female outer pipe 3 The annular space between the inner wall of the tube and the outer wall of the parent inner tube 4 forms the parent fuel channel 6; the annular space between the inner wall of the parent inner tube 4 and the outer wall of the first-stage sub-burner 2 forms the parent oxidizer channel 7; A female fuel inlet 8 is provided on the female cover plate 5 or a side wall of the female outer pipe 3 ; a female oxidizer inlet 9 is provided on the sid...

Embodiment 3

[0037] A gasification burner, similar to Embodiment 2, the difference is that the body of the female burner 1 is provided with a female body mounting flange 10 connected to the gasifier body; the tail of the female burner 1 A female tail mounting flange 11 connected to the first-stage sub-burner 2 is provided.

[0038] Preferably, the body of the sub-burner 2 is provided with a sub-body mounting flange 19 connected to the parent burner 1; The flange 20, or the tail of the sub-burner 2 of the last stage is provided with a sub-tail installation flange 20 connected with external equipment.

[0039] It should be noted that the external device may be a blind flange, an ignition device or a flame monitoring device, etc. In this way, the fully automatic ignition and flame monitoring and control functions of the gasification burner can be realized.

[0040] Preferably, the main burner 1 and each sub-burner 2 are connected as a whole by installing flanges respectively.

[0041] It s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com