Novel flue gas distributor device with adjustable air flue flow section

An adjustable flow section technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of uneven mixing of flue gas and atomized droplets, inconsistent design values, Unable to adjust the size and direction of the flue gas at the outlet of the internal and external air ducts of the distributor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

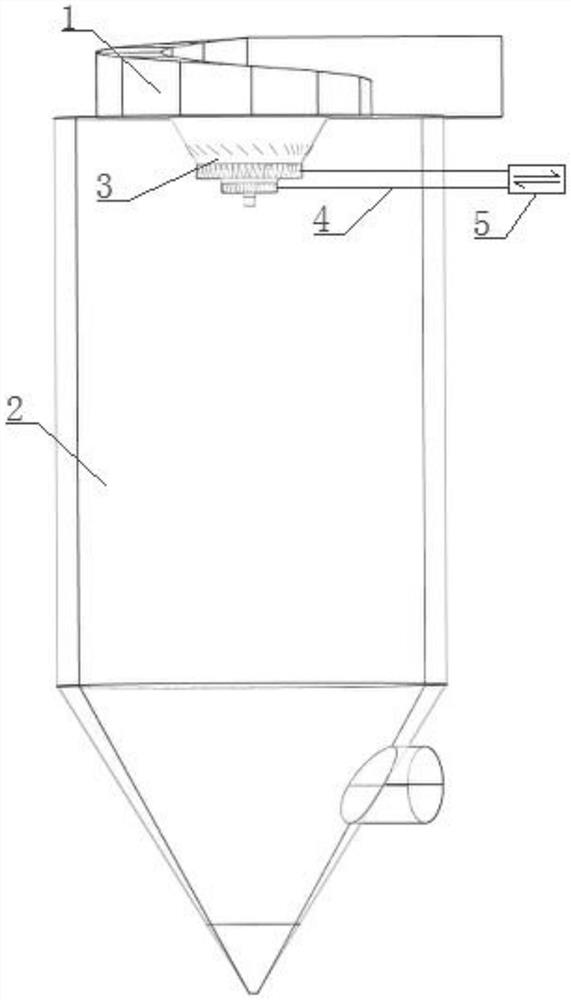

[0029] Embodiment 1 of the present application provides a method such as Figure 1 to Figure 2 The new type of flue gas distributor device with adjustable air duct flow section as shown:

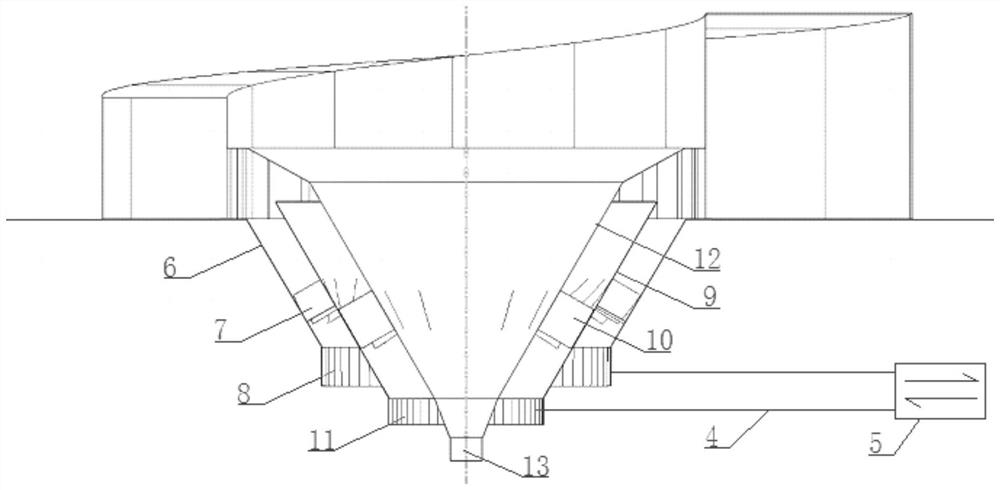

[0030] The device is mainly composed of an inner smoke distributor body 12, an inner air duct cone ring 9, an inner air duct deflector 10, an inner air duct adjustable fan blade 11, an outer air duct cone ring 6, and an outer air duct deflector 7. The external air duct is composed of adjustable fan blades 8, traction wire ropes 4, and motor actuators 5.

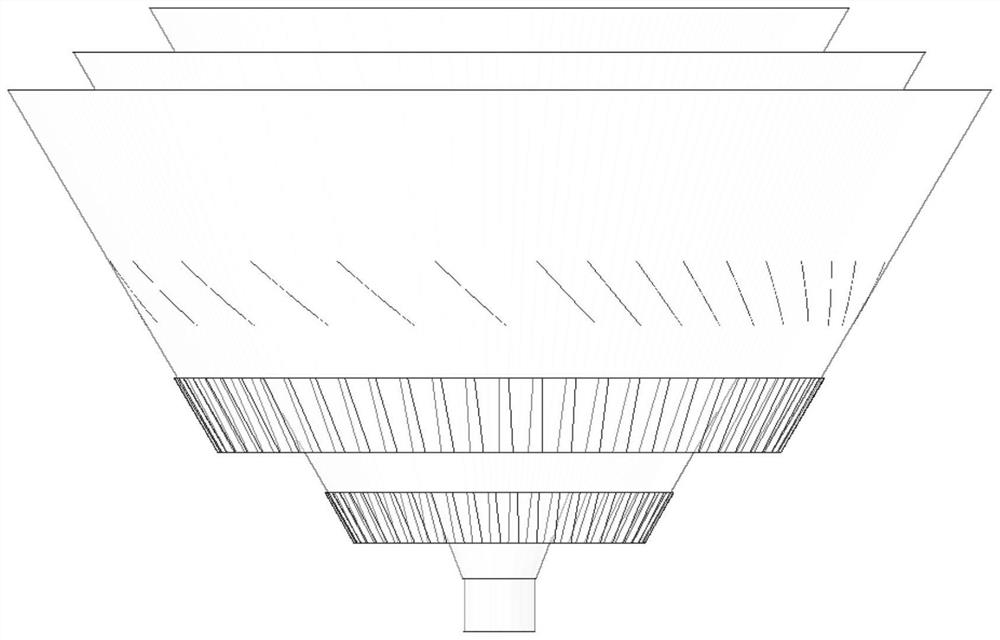

[0031] Adjustable fan blades are arranged at the outlets of the tapered ring 9 of the inner air duct and the tapered ring 6 of the outer air duct. ) connection, fan blades (outer air channel adjustable fan blade 8, inner air channel adjustable fan blade 11) are evenly arranged around the central axis of the tapered ring, and the fan blades are staggered and covered, and there is no gap between the blades.

[0032] Such as Figure 3 to Fi...

Embodiment 2

[0035] On the basis of the first embodiment, the second embodiment of the present application provides the working method of the novel flue gas distributor device with adjustable air duct flow section in the first embodiment:

[0036] The adjustable blade control strategy is:

[0037] When the amount of waste water decreases during operation, the corresponding amount of flue gas decreases, and the flow velocity of the inner and outer channels of the flue gas distributor (inner air duct cone ring, outer air duct cone ring) becomes smaller. The thermal efficiency is weakened, and the suppression effect of the smoke screen on the spray becomes worse. The angle of the inner and outer air duct blades (inner air duct adjustable fan blades, outer air duct adjustable fan blades) can be adjusted to increase the smoke flow rate and reduce the smoke screen. range, suppress the spray radius, prevent the droplets from sticking to the wall, and at the same time achieve the effect of strengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com