Parallel configuration power system of expansion machine

A power system and expander technology, which is applied in the field of parallel configuration power systems, can solve the problems of large changes in the working conditions of the power system, the inoperability of the expander, and the reduction of the efficiency and operating range of the power system under all working conditions. significant practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make those skilled in the art better understand the solution of the present invention, the present invention is further described in detail below with reference to the accompanying drawings and embodiments.

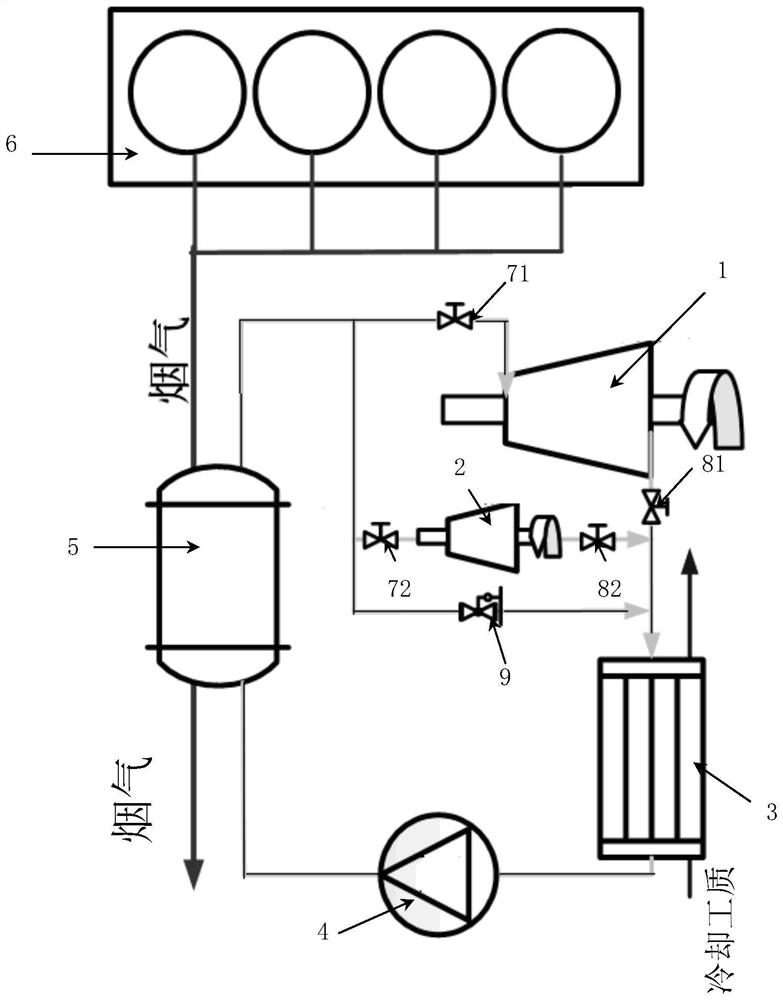

[0028] see figure 1 , the present invention provides a parallel configuration power system of an expander, comprising a main expander 1 and at least one auxiliary expander 2 ( figure 1 is shown in the case of an auxiliary expander), as well as the evaporator 5 and the internal combustion engine 6;

[0029] The flue gas outlet of the internal combustion engine 6 is communicated with the air inlet (that is, the flue gas inlet) at one end of the evaporator 5 (through a hollow connecting pipe);

[0030] The other end of the evaporator 5 has a flue gas outlet;

[0031] The outlet of the working medium of the evaporator 5 is respectively connected with a main expander branch, at least one auxiliary expander branch and a bypass branch;

[0032] The main exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com