Systems and Methods Using an Unmixed Fuel Processor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

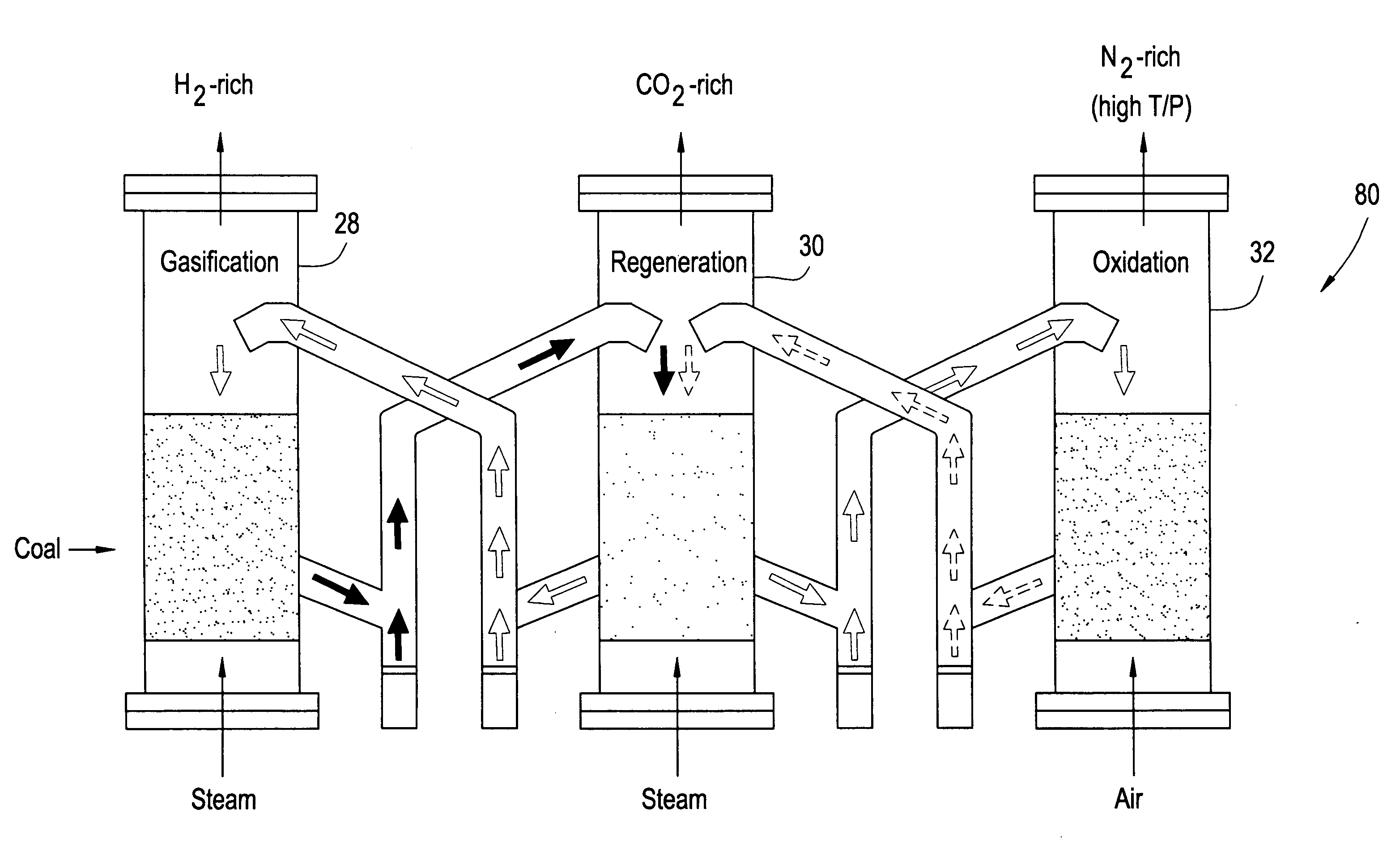

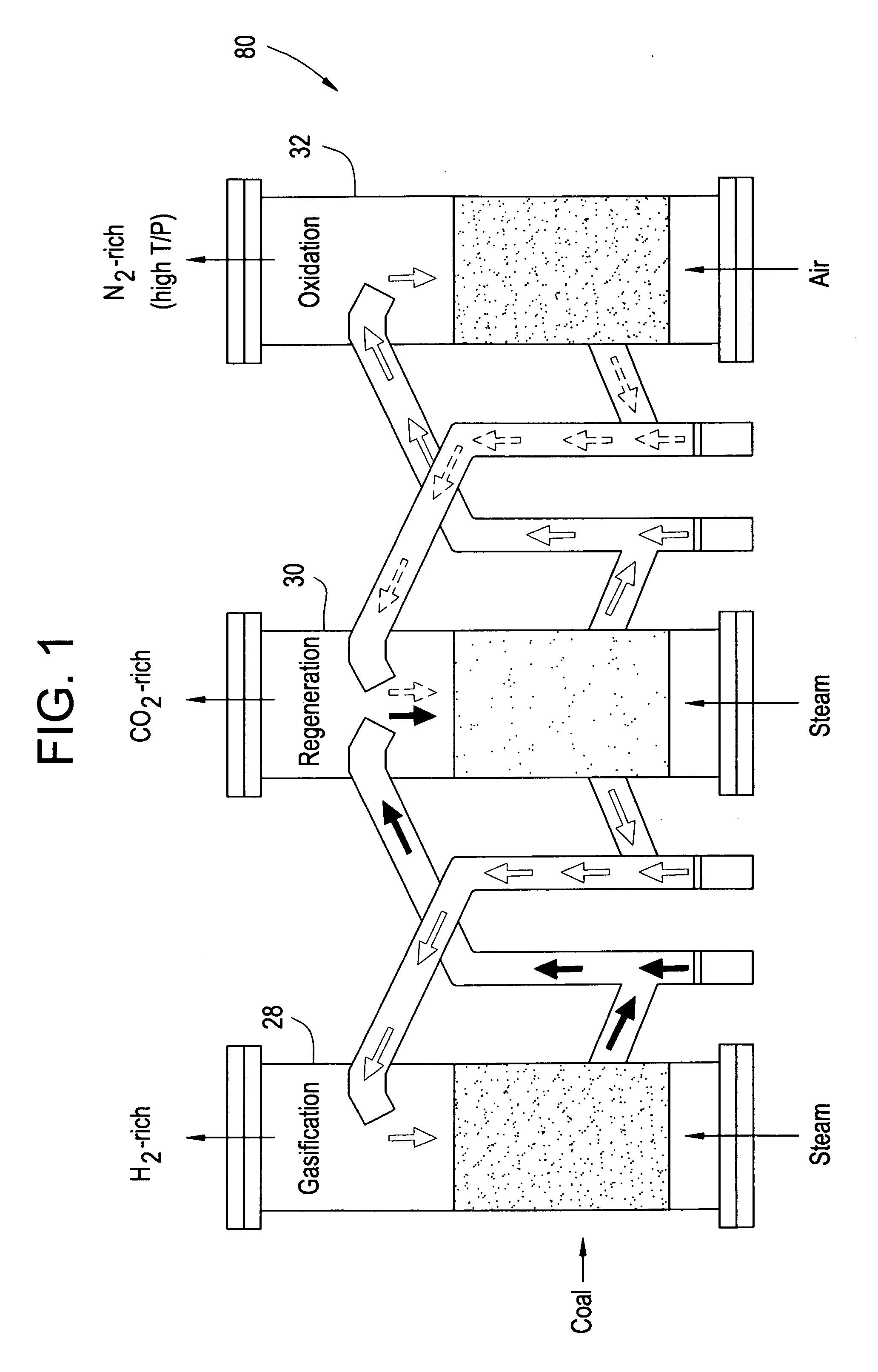

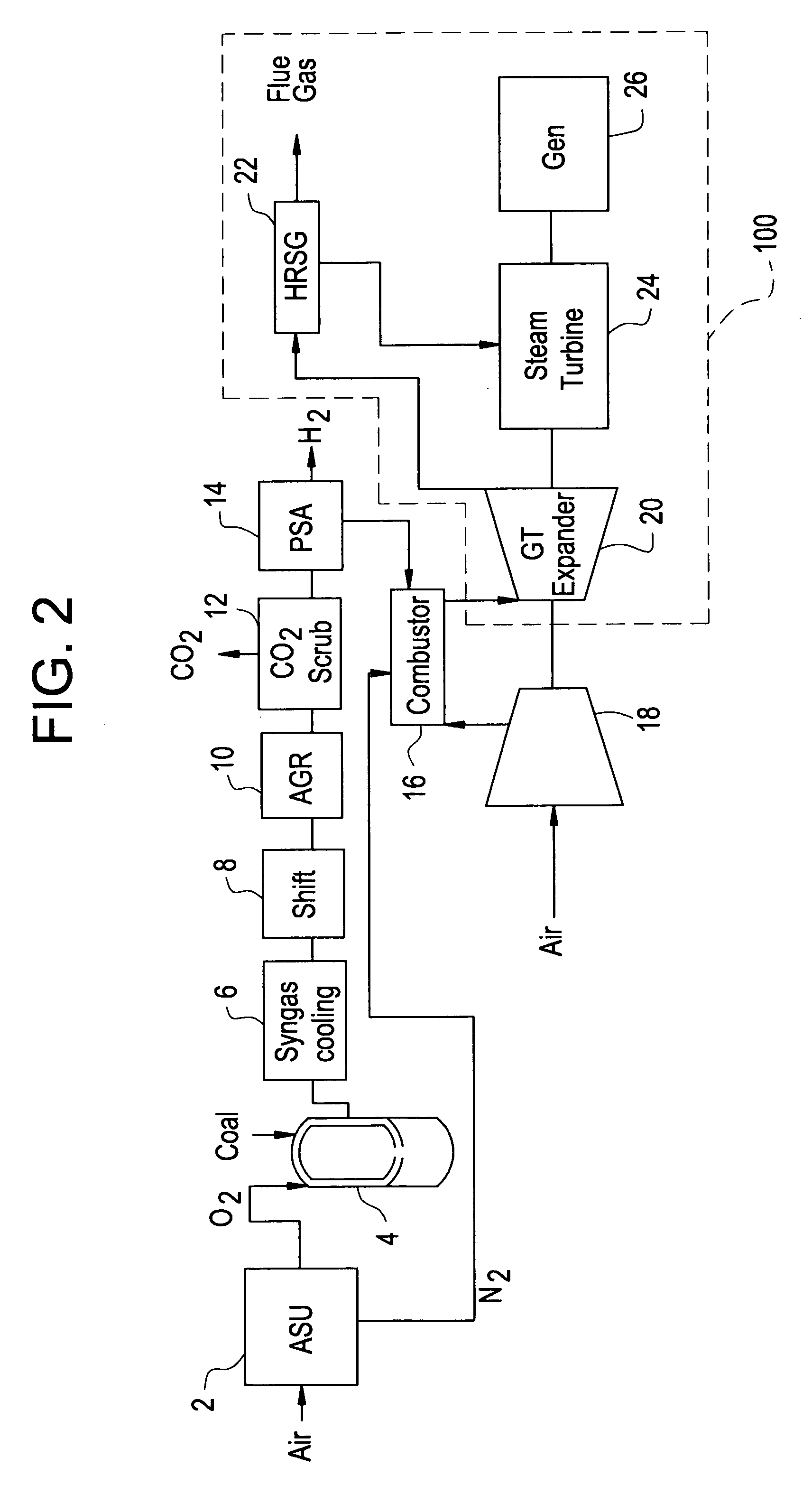

[0017]Integrated gasification combined cycle (IGCC) technology is well suited to better meet the needs for power generation from coal more cleanly than other technologies. It is also compatible with carbon sequestration and production of hydrogen fuel. Also, since unmixed fuel processor (UFP) technology offers the potential for reduced cost, increased process efficiency, and / or lower emissions relative to other gasification and combustion systems, a combination of the combined cycle (CC) and UFP technologies could be improve efficiency in an environmentally friendly fashion. This combined technology could be employed in conjunction with fuel cells and / or with additional plants (e.g., urea and / or ammonia generating plants) to produce electricity, urea, and / or ammonia, while also producing a stream that is ripe for CO2 sequestration.

[0018]Referring now to the figures, wherein like elements in the several figures are numbered alike for convenience and clarity of the figures, but are no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com