Aeration control system and aeration control method

A technology of control system and control method, applied in the direction of water aeration, water treatment parameter control, chemical instruments and methods, etc., can solve the problems that have not been fully popularized, need hours or even days, and are expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

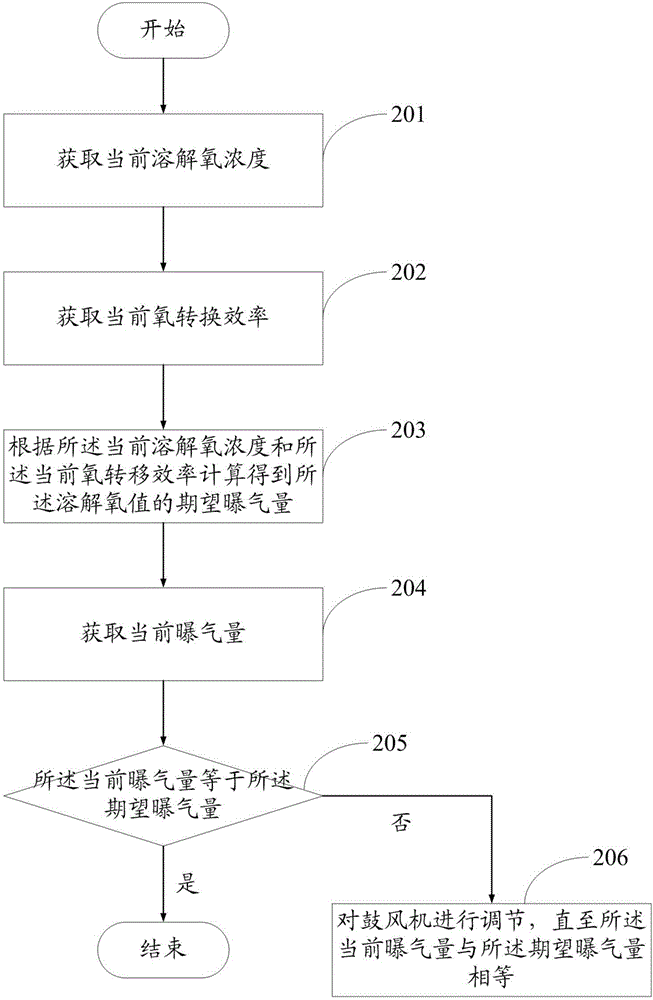

[0102] Set the desired dissolved oxygen concentration. The set dissolved oxygen value is to make the actual aeration amount as close or consistent as possible to the expected value by changing the aeration amount;

[0103] Adjust the air volume of the blower according to the change of oxygen transfer efficiency (OTE) and the change of DO actual value;

[0104] The fan is adjusted according to the aeration rate described.

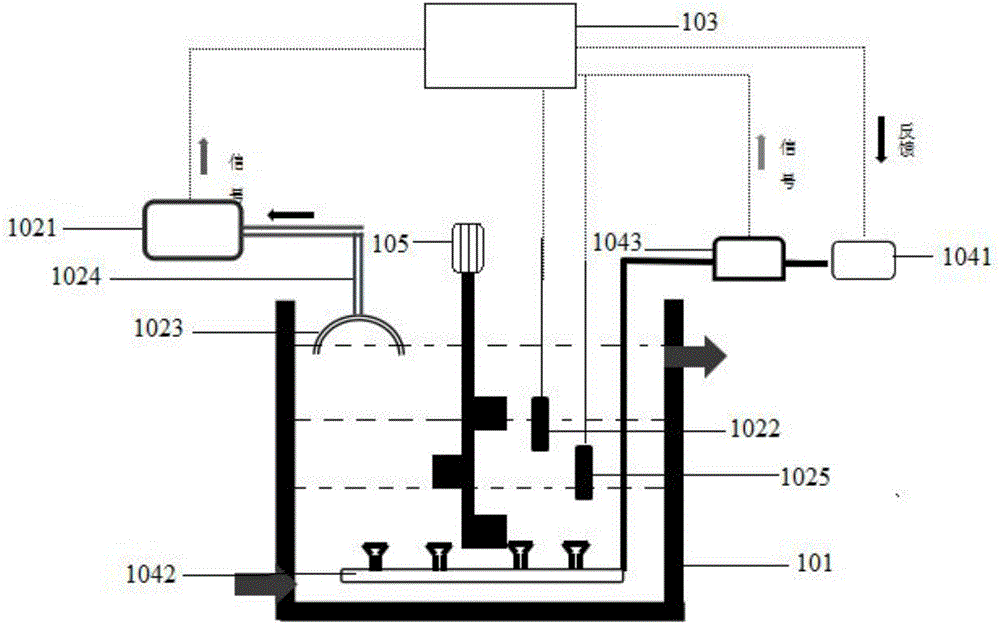

[0105] First, the control program algorithm is written into the control unit 103 through software. When the aeration control system starts to operate, the DO detector 1022 measures the DO concentration in the sewage in real time, and sends it to the control unit 103 through the Profibus communication line. The control unit 103 will dissolve according to the actual situation. The difference between oxygen and the set dissolved oxygen selects the control mode, integrates the real-time feedback data of the OTE meter 1021 and the DO meter 1022, calculates the re...

Embodiment 2

[0109] Taking Sequencing Batch Reactor Activated Sludge Process (SBR) as an example, the effective volume of the aeration tank is 82.5m 3 , the effective water depth is 3.3m, the set value of C=2.0mg / L, the t control period is 10 minutes, [O 2 air] is the density of oxygen in the air is 0.28kg / m 3 ;

[0110] Taking Siemens 300 series programmable logic controller (Programmable Logic Controller, PLC) as an example, it is composed of special software modules and function modules.

[0111] In particular, in order to improve the reliability and flexibility of system transmission, the system uses a Profibus communication line with a faster transmission rate to connect the system in series;

[0112] In particular, the hood is made of lightweight rubber material combined with steel material;

[0113] In particular, the aerator adopts a microporous aerator with a pore size of 50-100 μm.

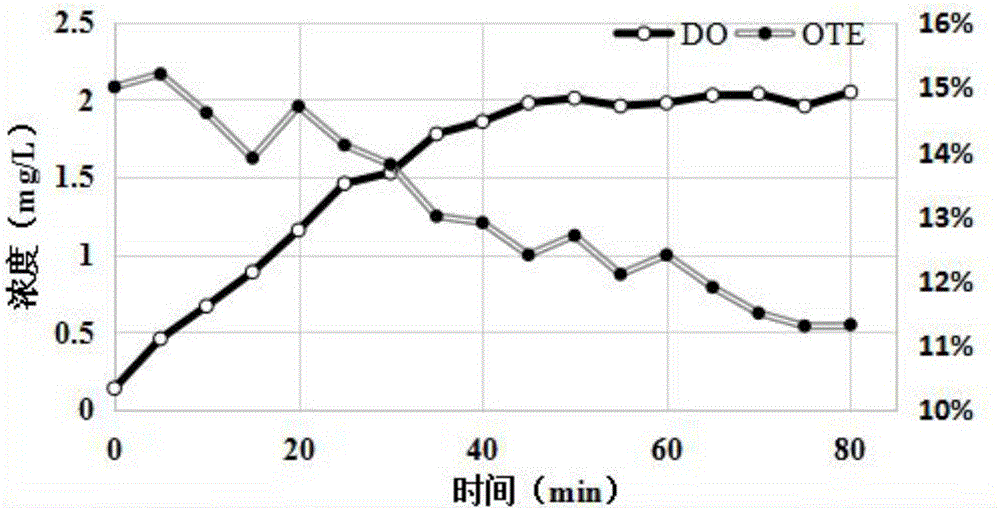

[0114] The initial setting value of dissolved oxygen is 2mg / L. After connecting the OTE meter...

Embodiment 3

[0119] At 5 minutes after aeration, when OTE=0.15, if the set value of DO=2.0mg / L, the actual value of DO=1.0mg / L, K La =0.371min -1 , α=0.48, C saturation value=8.41mg / L, β=0.89, t control period=10min, T=24℃, oxygen density in air is 0.28kg / m 3 , then Q=161.35m 3 / h;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com