Method for catalytic degradation of high-concentrated organic wastewater by micro-wave cooperating with perovskite

A technology for organic wastewater and catalytic degradation, applied in the field of water treatment, to achieve the effects of wide application range, easy operation, good oxygen storage capacity and oxygen transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] First La(NO 3 ) 3 and Fe(NO 3 ) 3 Prepare a mixed aqueous solution with a ratio (molar ratio) of 1.0:1.0, control the total concentration of all metal ions in the solution to be 0.5~1.5 mol / L, and then press citric acid and metal ions (La 3+ + Fe 3+ ) with a molar ratio of 1.0:1.0, add citric acid, mix and stir the solution at 80°C, evaporate to 1 / 3 of the volume of the original solution, put it in an oven and dry and dehydrate at 120-130°C to form Loose dry gel. Then continue to raise the temperature of the oven to 140-180°C to cause the violent decomposition of the metal nitrate to obtain the catalyst precursor. Finally, the catalyst precursor was calcined at 800 °C for 4 hours to obtain LaFeO 3 Perovskite-type metal composite oxide catalyst.

[0026] This catalyst was applied to the treatment of methyl orange simulated printing and dyeing wastewater. Measure 25 mL of methyl orange solution with a concentration of 50 mg / L and place it in the reactor, add 0.1 ...

Embodiment 2

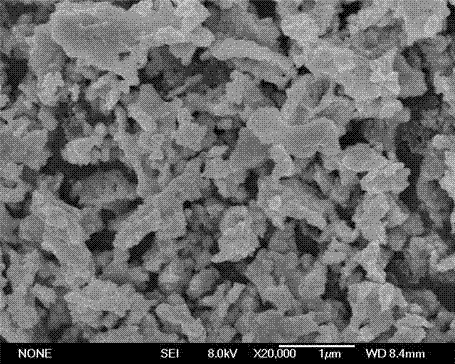

[0028] Ce(NO 3 ) 2 , La(NO 3 ) 3 and Fe(NO 3 ) 3 The molar ratio is 0.2:0.8:1.0 preparation mixed solution, other conditions are identical with embodiment 1, prepare La 0.8 Ce 0.2 FeO 3 Perovskite-type metal composite oxide catalyst, its scanning electron microscope photo is as follows figure 1 shown.

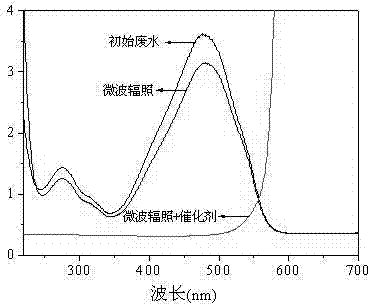

[0029] This catalyst was applied to the treatment of methyl orange simulated printing and dyeing wastewater. Such as figure 2 As shown, the degradation of methyl orange by microwave irradiation alone is very limited, adding 0.2g La to the system 0.8 Ce 0.2 FeO 3 After the catalyst was irradiated for 9 minutes under the same microwave power of 540W, the removal rate of methyl orange could reach 94.1%. Depend on image 3 It can be seen that the simulated wastewater has been basically decolorized after degradation.

Embodiment 3

[0031] The catalyst prepared in Example 2 was used to treat methyl orange simulated printing and dyeing wastewater. Using the same experimental method as in Example 2, changing the amount of the catalyst, and investigating the degradation performance of the simulated wastewater. Such as Figure 4 As shown, the dosage is as Figure 4 As shown in , with the increase of catalyst dosage, the removal rate of methyl orange gradually increased. When the amount of catalyst is 0.2g, the removal rate of methyl orange can reach 93.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com