Integrated bubbleless aeration membrane bioreactor

A membrane bioreactor, bubble-free aeration technology, applied in sustainable biological treatment, aerobic process treatment and other directions, can solve the problems of material-liquid mixing device defects, unreasonable membrane structure, high cost, and achieve convenient and accurate control of aeration Gas volume, convenient operation, and the effect of meeting the needs of oxygen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

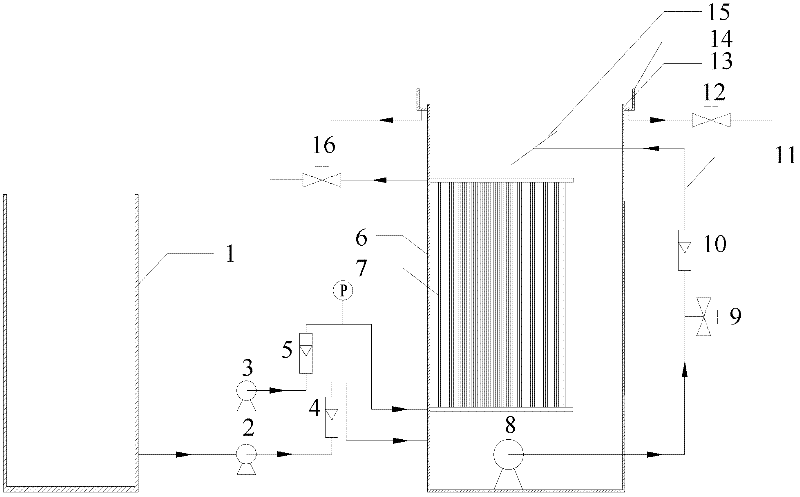

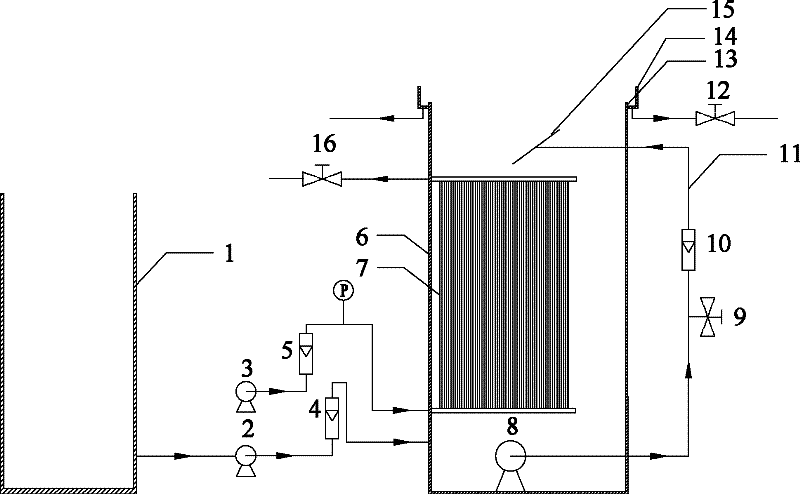

[0026] refer to figure 1 , an integrated non-foam aeration membrane bioreactor, with a biochemical reactor 6, a hollow fiber curtain membrane 7 is vertically placed in the biochemical reactor 6, and the hollow fiber curtain membrane 7 is made of hydrophobic polyvinylidene fluoride. Vinyl material. The upper and lower ends of the hollow fiber curtain membrane 7 are respectively fixed in the side wall of the single-pass PVC pipe with resin. It is connected with the exhaust pipe, the intake pipe is connected with the air compressor 3 through the air rotameter 5 , and the exhaust pipe leads to the air through the gas fine-tuning valve 16 .

[0027] The instrument is provided with a feeding box 1, which is communicated with the lower part of the biochemical reactor 6 through a sewage conveying pipeline, and a booster pump 2 and a liquid rotameter 4 are arranged on the sewage conveying pipeline. The top of the biochemical reactor 6 is provided with an overflow weir 13 , an overflo...

Embodiment 2

[0030] like figure 1 As shown in Example 1, the submersible pump 8 is also provided at the bottom of the biochemical reactor 6, the submersible pump 8 is connected with the outer circulation pipeline 11, and the outer circulation pipeline 11 is connected to the hollow fiber curtain membrane 7 Above, the outer circulation pipeline 11 is provided with a throttle valve 9 and a liquid rotameter 10. Two branch return pipes 15 are provided at the end of the outer circulation pipeline 11 above the hollow fiber curtain membrane 7 , and the two branch return pipes 15 are located on both sides of the hollow fiber curtain membrane 7 .

[0031] The apparatus described in Example 2 can simultaneously realize the plug flow operation and the fully mixed flow operation of the material.

[0032] The working process is as follows: the sewage passes through the booster pump 2, and is fed into the biochemical reactor 6 from the feeding box 1, and the feeding time is controlled by the liquid rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com