Air separation high-pressure plate type heat exchange system and purging method

A technology of heat exchange system and high-pressure plate, which is applied in the field of air separation high-pressure plate heat exchange system and purging, which can solve the problems of blockage of high-pressure plate heat exchanger, poor heat exchange effect of heat exchanger, continuous decrease of oxygen load, etc. Achieve the effect of reducing economic losses and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

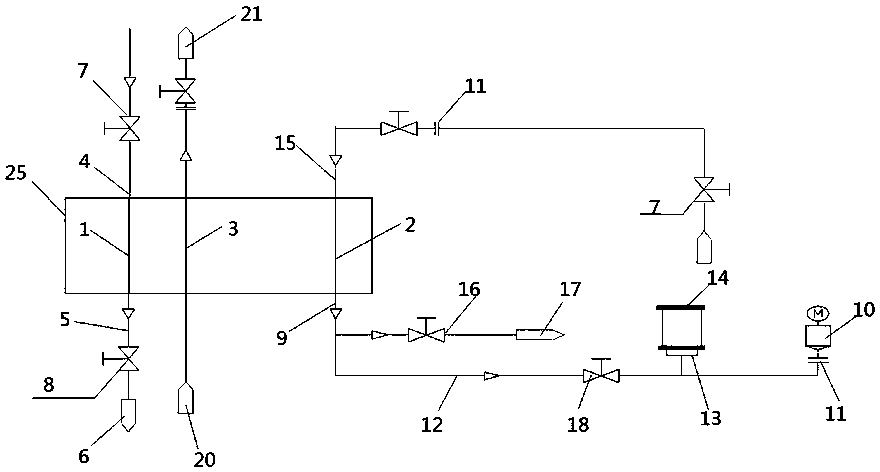

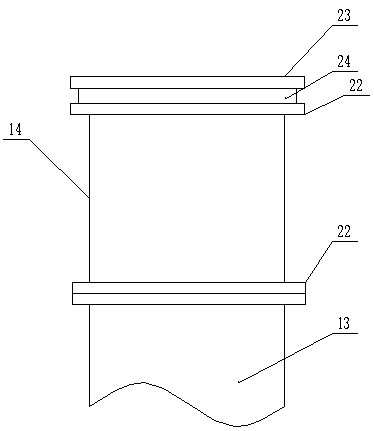

[0052] This method is applicable to multiple sets of parallel air separation heat exchange systems. When multiple sets of parallel air separation heat exchange systems are used, one set of systems is in normal operation, and the other set of systems is purged. Air comes from the system in normal operation.

[0053] The multiple sets of parallel air separation heat exchange systems include A set of systems and B sets of systems running in parallel, and the A set of systems and B set of systems all include a high-pressure plate heat exchanger 25, and the high-pressure plate heat exchanger includes Air channel 1, nitrogen channel 3 and oxygen channel 2, under the normal operation state of set B system, purging for set A system, the heated air used for purging comes from set B system under normal operation state, for air separation high pressure The purging method of the plate heat exchange system comprises the following steps:

[0054] Step 1: Drain liquid from air channel 1 of ...

Embodiment 2

[0084] A purging method for an air separation high-pressure plate heat exchange system, when applied to an independent set of air separation heat exchange system, the air separation high-pressure plate heat exchange system includes a high-pressure plate heat exchanger, and the high-pressure plate heat exchanger includes air Channel, nitrogen channel and oxygen channel, described purging method comprises the following steps:

[0085] Step 1: Drain liquid from the air channel of the high-pressure plate heat exchanger and reheat the air channel, close the oxygen channel, open the valve of the air channel, and use heated air to perform reheating from the air channel;

[0086] Step 2, the liquid oxygen channel of the high-pressure plate heat exchanger is temporarily connected with a fake piece, the liquid oxygen pump at the liquid oxygen outlet is closed, and a blind plate is used to seal the liquid oxygen pump inlet; a blasting discharge pipeline is set on the liquid oxygen outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com