A method for smelting and reducing iron ore using a converter steelmaking system

A converter steel and iron ore technology, applied in the direction of manufacturing converters, etc., can solve the problems of high production energy consumption, inconvenient promotion and use, high smelting cost, and achieve the effect of improving stability and solving the problem of furnace lining life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

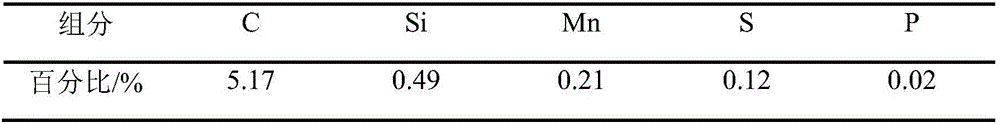

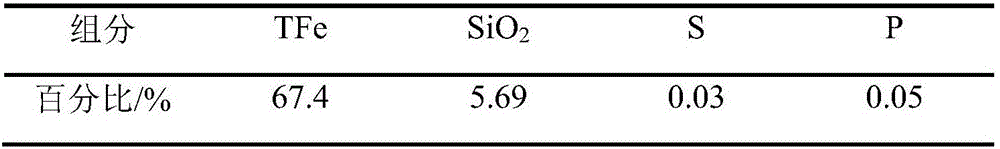

[0031] A method of smelting and reducing iron ore using a converter steelmaking system in this embodiment, the main components of the selected molten iron and the mass percentages of the iron ore components are shown in Table 1 and Table 2:

[0032] Table 1 The main components of molten iron

[0033]

[0034] The mass percent of table 2 iron ore composition

[0035]

[0036] The technological operation process of this embodiment is as follows: after the converter is splashed with slag to protect the furnace, 70t of molten iron accounting for 70% of the tonnage of the converter is mixed into the converter. When blowing starts, the oxygen lance position is 1100mm, which is 55mm lower than the normal lance position. Within 1-3 minutes of blowing, 2t of iron ore, 1.5t of limestone and 1.5t of dolomite are added, and the particle size of iron ore is 10-50mm. Moisture <2%, return to normal gun position after 3 minutes. Continuously add iron ore, limestone and dolomite in batch...

Embodiment 2

[0038] The process of the present embodiment is as follows: after the converter is protected by slag splashing, 80t of molten iron accounting for 80% of the tonnage of the converter is mixed into the converter. When blowing starts, the position of the oxygen lance is 50mm lower than the normal one. Within 1-3 minutes of blowing, add 1.5t of iron ore, 1t of limestone and 1t of dolomite. , and return to the normal gun position after 3 minutes. Continuously add iron ore, limestone and dolomite in batches. The timing and amount of adding iron ore, limestone and dolomite are based on the thickness of the foam slag layer, so that the thickness of the foam slag is moderate and the distance between the foam slag layer and the furnace mouth is kept 300~600mm. Specifically, each batch of iron ore in this embodiment is 1.5t, each batch of limestone is 200kg, and each batch of dolomite is 200kg. Among them, when adding iron ore, lift the gun 25mm, and return to the normal gun position a...

Embodiment 3

[0040] The technological operation process of this embodiment is as follows: after the converter is splashed with slag to protect the furnace, firstly, 60 tons of molten iron is mixed into the converter, accounting for 60% of the capacity of the converter. When blowing starts, the position of the oxygen lance is 100mm lower than the normal one. Within 1-3 minutes of blowing, add 3t of iron ore, 2t of limestone and 1t of dolomite. Return to normal gun position after 3 minutes. Continuously add iron ore, limestone and dolomite in batches. The timing and amount of adding iron ore, limestone and dolomite are based on the thickness of the foam slag layer, so that the thickness of the foam slag is moderate and the distance between the foam slag layer and the furnace mouth is kept 300~600mm. Specifically, in this embodiment, each batch of iron ore is 1 ton, each batch of limestone is 400 kg, and each batch of dolomite is 400 kg. Among them, when adding iron ore, lift the gun 20mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com