Impeller of externally mixed type self-priming pump

A self-priming pump and impeller technology, applied in the field of external mixing self-priming pump impeller, can solve the problems of poor gas-liquid mixing, slow water supply speed, and long gas discharge time, and achieve large contact area, fast water supply speed, and discharge short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

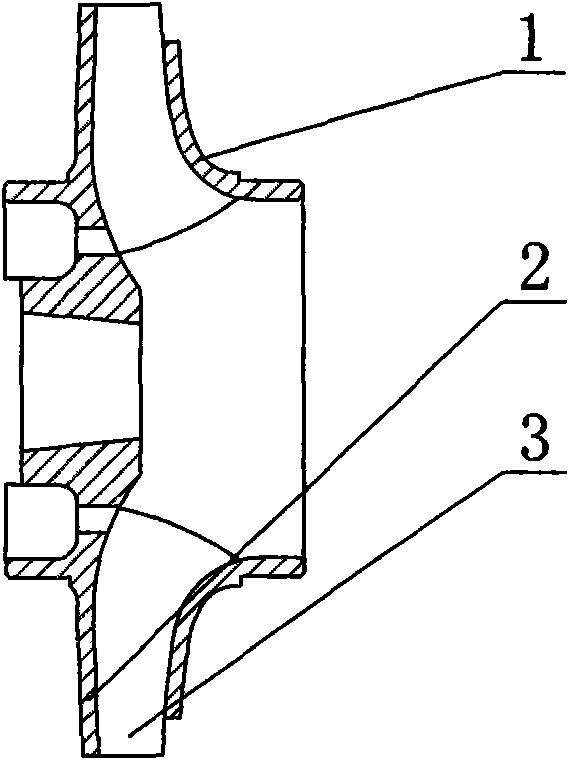

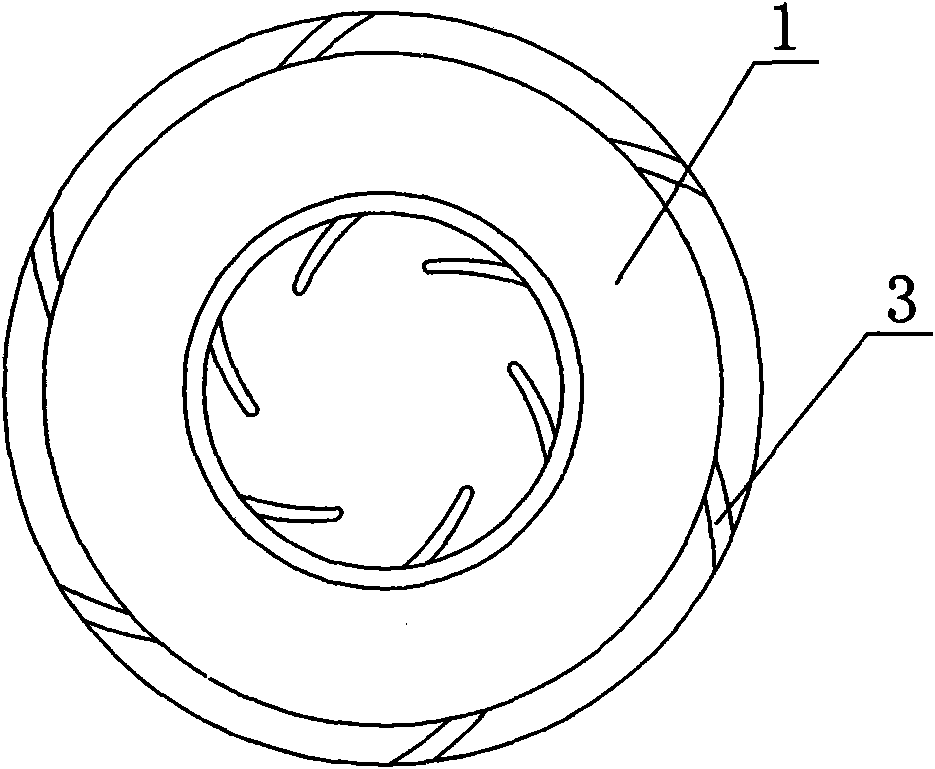

[0013] Such as figure 1 , figure 2 The external mixing self-priming pump impeller shown has a front cover 1 and a rear cover 2 on the impeller, a blade 3 is provided between the front cover 1 and the rear cover 2, and an annular cutout is provided on the outer diameter of the cover. It can be seen from the figure that the outer diameter of the front cover plate 1 is provided with an annular cut-off zone, the blades at the annular cut-off zone are not covered by the cover plate, the blades are exposed, and the contact area between the blades and the liquid is large. Strong agitation, good gas-liquid mixing, short gas discharge time, and fast water filling.

Embodiment 2

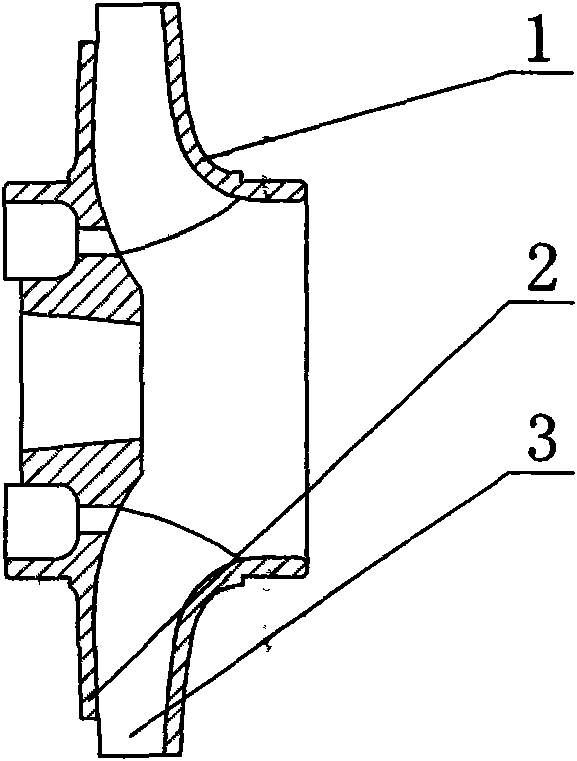

[0015] Such as image 3 , Figure 4 In the shown external mixing self-priming pump impeller, the outer diameter of the cover plate is provided with an annular cutout zone, and it can be seen from the figure that the outer diameter of the rear cover plate 2 is provided with an annular cutout zone. Other structures are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0017] Such as Figure 5 , figure 2 , Figure 4 In the shown external mixing self-priming pump impeller, the outer diameter of the cover plate is provided with an annular cut-off zone, and it can be seen from the figure that the outer diameter of the front cover plate 1 and the rear cover plate 2 are respectively provided with an annular cut-off zone. Other structures are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com