Method of swinging electric arc welding with double hollow cathodes

An arc welding method and a hollow cathode technology are applied in arc welding equipment, welding equipment, manufacturing tools, etc. to achieve the effects of improving welding penetration, reducing the range of heat-affected zones, and increasing energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

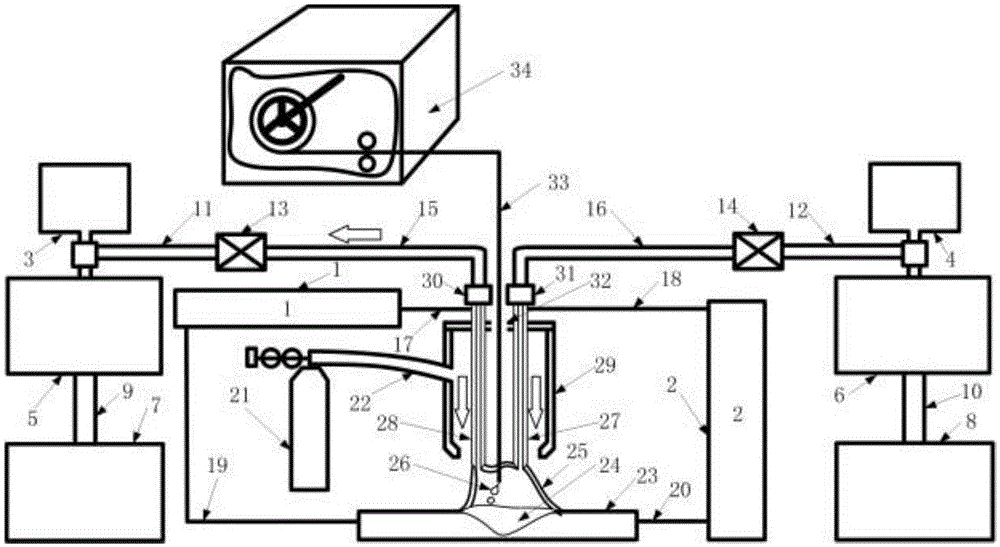

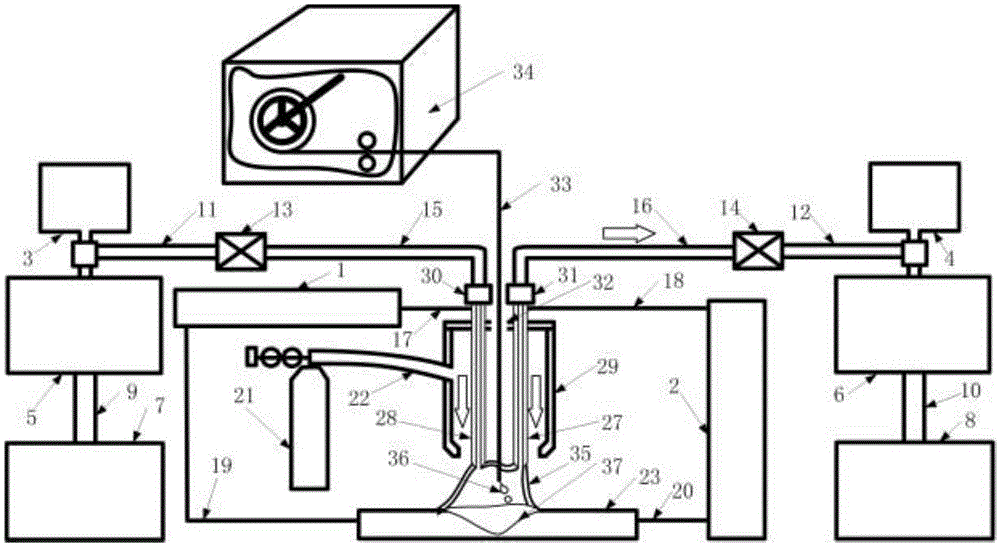

[0033] Embodiments of the present invention will be specifically described below with reference to the drawings.

[0034]First connect the welding circuit and the gas circuit device, connect one end of the welding power supply and control system 1 to the hollow tungsten electrode 28 through the welding cable 17 , and connect the other end to the welding workpiece 23 through the welding cable 19 . One end of the welding power supply and control system 2 is connected to the hollow tungsten electrode 27 through the welding cable 18 , and the other end is connected to the welding workpiece 23 through the welding cable 20 . The air extraction device 7 , the pressure release device 5 , the pressure display device 3 , the valve 13 and the hollow tubular tungsten electrode 28 are communicated through the air guide lines 9 , 11 , and 15 , wherein the air guide line 15 is connected to the hollow tungsten electrode 28 through the connection joint 30 . Air extraction device 8 , pressure r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com