A tig welding method for lap joint of titanium-based composite material and nickel-based alloy with cu intermediate layer

A technology of titanium-based composite materials and nickel-based alloys, applied in welding equipment, metal processing equipment, arc welding equipment, etc., can solve the problems of brittle Ti-Ni phases, large joint stress after welding, and difficult connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

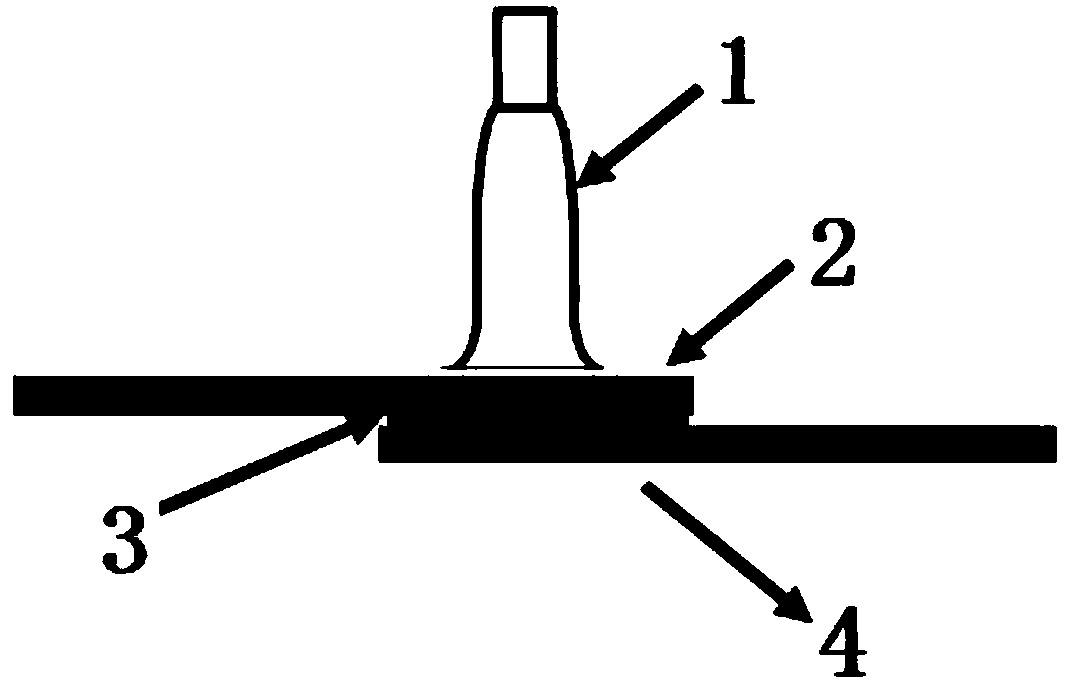

[0012] Specific embodiment 1: The TIG welding method of a titanium-based composite material and a nickel-based alloy with Cu interlayer overlapping in this embodiment is carried out according to the following steps:

[0013] The titanium-based composite material and the nickel-based alloy are processed into plates with a thickness of 2.0 mm, polished and cleaned respectively to obtain the titanium-based composite plate and the nickel-based alloy plate; the titanium-based composite plate and the nickel-based alloy plate are overlapped, Then place the Cu intermediate layer with a thickness of 0.1 mm to 0.2 mm in the middle of the overlapping parts of the titanium-based composite sheet and the nickel-based alloy sheet to obtain the piece to be welded; fix the piece to be welded on the welding platform in the welding sealed box, The titanium-based composite plate is located on the upper part, and high-purity argon gas is introduced into the welding sealed box as a protective gas fo...

specific Embodiment approach 2

[0015] Embodiment 2: This embodiment differs from Embodiment 1 in that: the titanium-based composite material is a network-structured TiBw / TC4 alloy-based composite material. Other steps and parameters are the same as those in the first embodiment.

[0016] The TiBw / TC4 alloy-based composite material with network structure is specifically prepared according to the following steps:

[0017] 1. Mechanical powder mixing: mix 3% TiB by mass percentage 2 Powder and 97% TC4 titanium alloy powder are mechanically mixed with a ball mill, and the mixing time is 4 to 12 hours;

[0018] 2. Hot pressing sintering: Put the mixed composite powder into a vacuumized airtight container for hot pressing sintering. The temperature is directly heated from room temperature to 1100-1500 °C, and the pressure is maintained at 15-30 MPa, and the pressure-holding time is 0.5-5 hours. , and the titanium-based composite material can be obtained after cooling to room temperature; wherein, the particle s...

specific Embodiment approach 3

[0019] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: the volume fraction of the reinforcing phase in the network structure TiBw / TC4 alloy matrix composite material is 5%. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com