Double Center Negative Pressure Arc Filling Wire Welding Method

A welding method and dual-center technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., to achieve the effect of improving welding efficiency, increasing energy density, and increasing welding heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

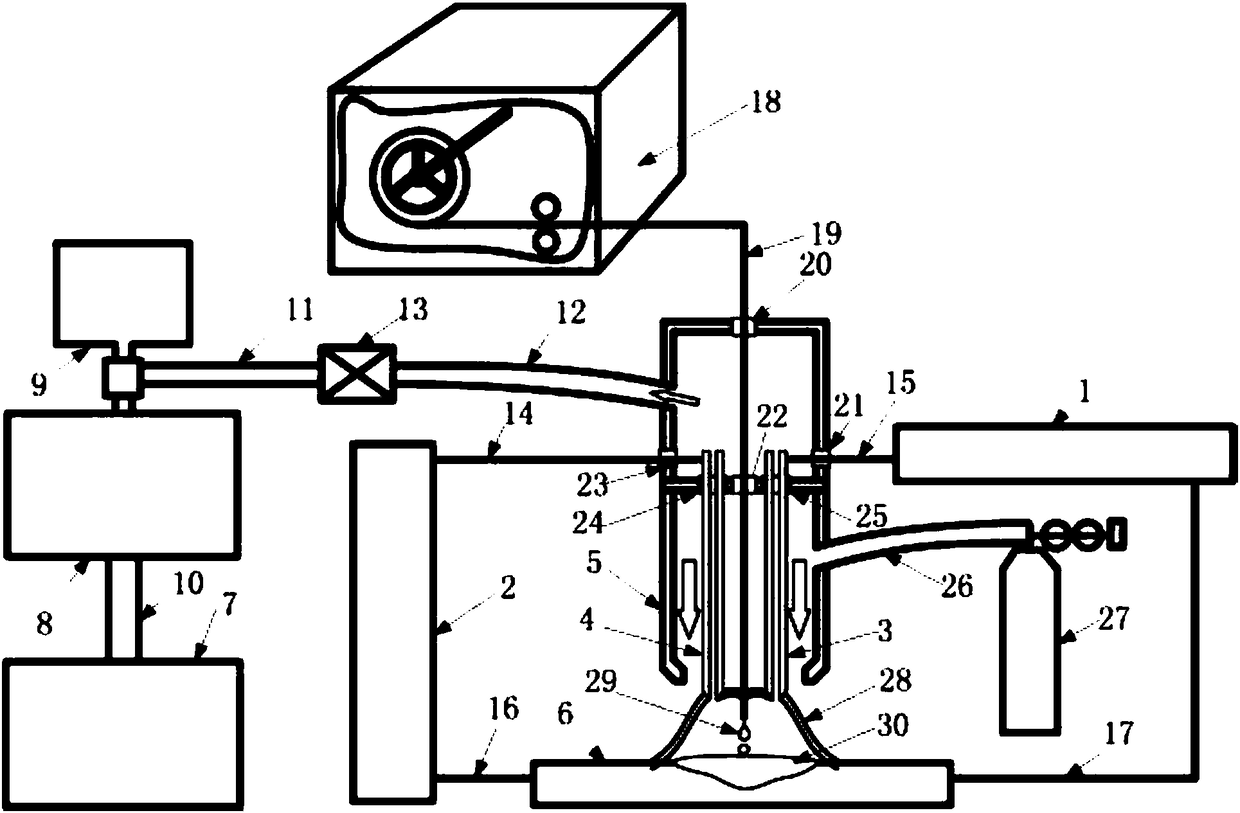

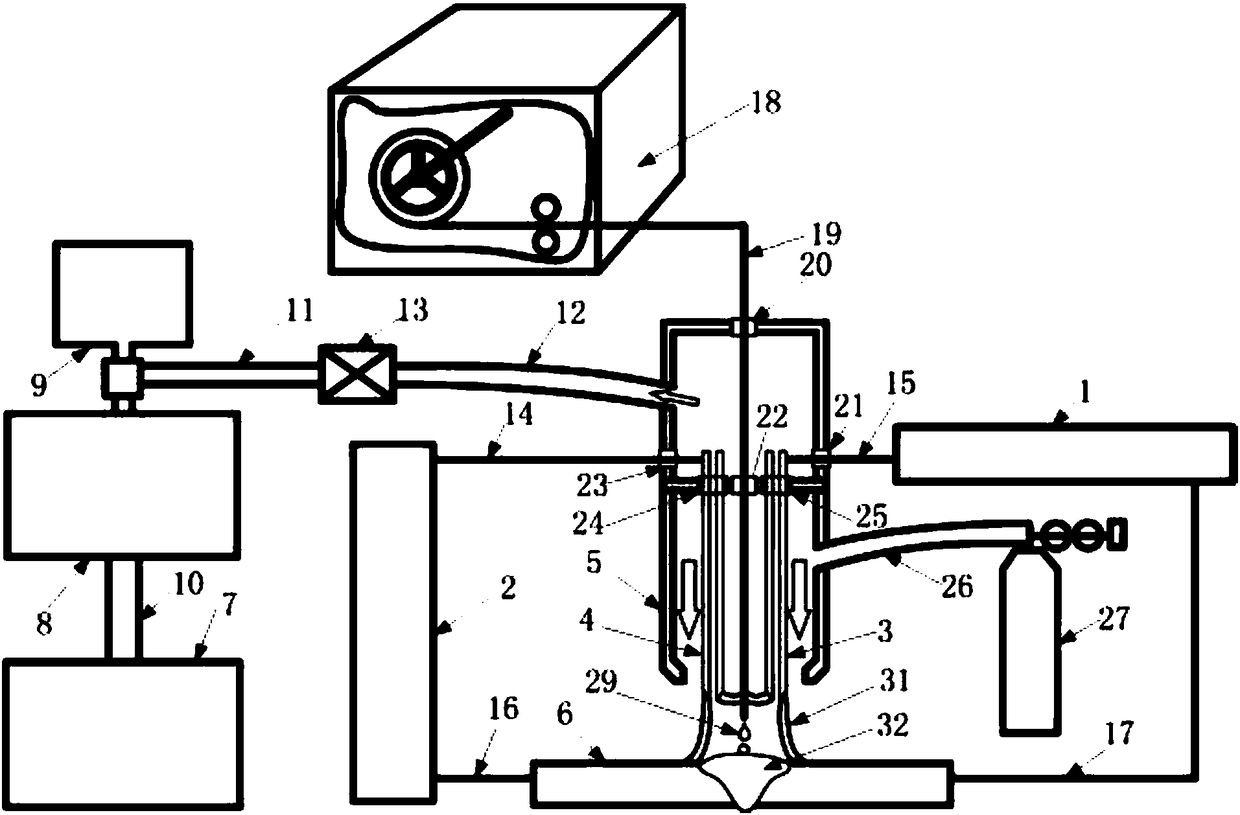

[0027] Embodiments of the present invention will be specifically described below with reference to the drawings.

[0028] Before welding, ensure that each water circuit, gas circuit and electric circuit are connected properly. First, connect the air extraction device 7, the pressure release device 8, the pressure display device 9, and the valve 13 through the air guide lines 10, 11, and 12. One end of the welding power supply and control system 1 is connected to the hollow tungsten electrode 3 through a welding cable 15 , and the other end is connected to the welding workpiece 6 through a welding cable 17 . One end of the welding power supply and its control system 2 is connected to the hollow tungsten electrode 4 through a welding cable 14 , and the other end is connected to the welding workpiece 6 through a welding cable 16 . The welding wire 19 is sent out through the wire feeding device 18 and sent vertically into the center of the coupling arc. At the same time, ensure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com