Method for producing rose vinegar by pneumatic stirring method

A technology of pneumatic stirring and rose vinegar, applied in the field of food fermentation engineering, can solve the problems of low production efficiency, high labor intensity, long production cycle, etc., and achieve the effects of improving efficiency, improving the degree of mechanization, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

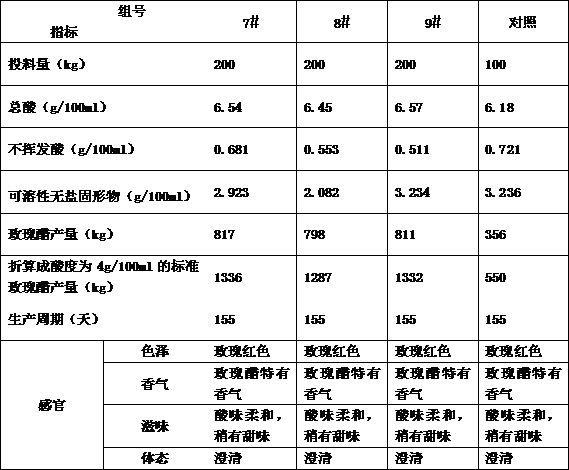

Embodiment 1

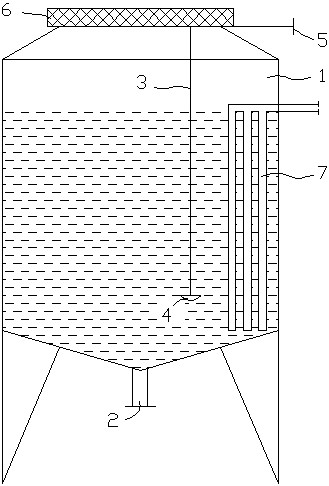

[0036] The present invention is a method for producing rose vinegar by a pneumatic stirring method, which comprises the steps of rinsing rice, steaming rice, cooling cooked rice, putting cooked rice into a tank (1) and building a nest, blooming, adding water, fermenting, The aging step, pressing step, and sterilization step are characterized in that: the tank (1) is cylindrical, the upper end of the tank (1) is open, and the lower end of the tank (1) is provided with a conical or arc-shaped bottom, The diameter-to-height ratio of the cylindrical portion of the tank (1) is D:H=1:0.8, the lowest point of the conical or arc-shaped bottom of the tank (1) is provided with a discharge port (2), and one end of the compressed air pipe (3) It is connected to the air inlet (5), and the other end is connected to the air nozzle (4) arranged at the lower part of the mash in the tank (1), and a grass cover (6) is provided on the upper port. The fermentation steps include:

[0037] (1) Ferme...

Embodiment 2

[0045] The present invention is a method for producing rose vinegar by a pneumatic stirring method, which comprises the steps of rinsing rice, steaming rice, cooling cooked rice, putting cooked rice into a tank (1) and building a nest, blooming, adding water, fermenting, The aging step, pressing step, and sterilization step are characterized in that: the tank (1) is cylindrical, the upper end of the tank (1) is open, and the lower end of the tank (1) is provided with a conical or arc-shaped bottom, The diameter-to-height ratio of the cylindrical portion of the tank (1) is D:H=1:0.9, the lowest point of the conical or arc-shaped bottom of the tank (1) is provided with a discharge port (2), and one end of the compressed air pipe (3) It is connected to the air inlet (5), and the other end is connected to the air nozzle (4) arranged at the lower part of the mash in the tank (1), and a grass cover (6) is provided on the upper port. The fermentation steps include:

[0046] (1) Ferme...

Embodiment 3

[0054] The present invention is a method for producing rose vinegar by a pneumatic stirring method, which comprises the steps of rinsing rice, steaming rice, cooling cooked rice, putting cooked rice into a tank (1) and building a nest, blooming, adding water, fermenting, The aging step, pressing step, and sterilization step are characterized in that: the tank (1) is cylindrical, the upper end of the tank (1) is open, and the lower end of the tank (1) is provided with a conical or arc-shaped bottom, The diameter-to-height ratio of the cylindrical portion of the tank (1) is D:H=1:1, the lowest point of the conical or arc-shaped bottom of the tank (1) is provided with a discharge port (2), and one end of the compressed air pipe (3) It is connected to the air inlet (5), and the other end is connected to the air nozzle (4) arranged at the lower part of the mash in the tank (1), and a grass cover (6) is provided on the upper port. The fermentation steps include:

[0055] (1) Ferment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com