External mixing self-priming pump impeller

A self-priming pump and impeller technology, applied in the field of external mixing self-priming pump impeller, can solve the problems of long gas discharge time, low efficiency, poor gas-liquid mixing, etc., and achieve the effect of short gas discharge time and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

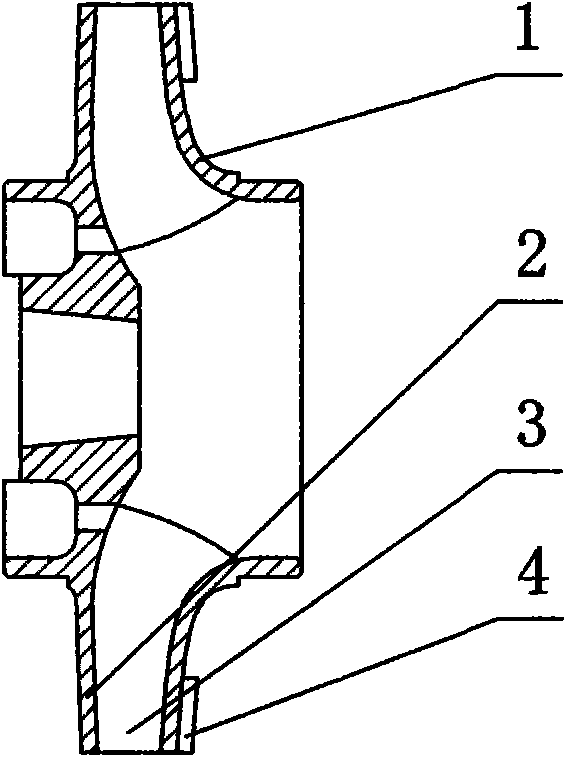

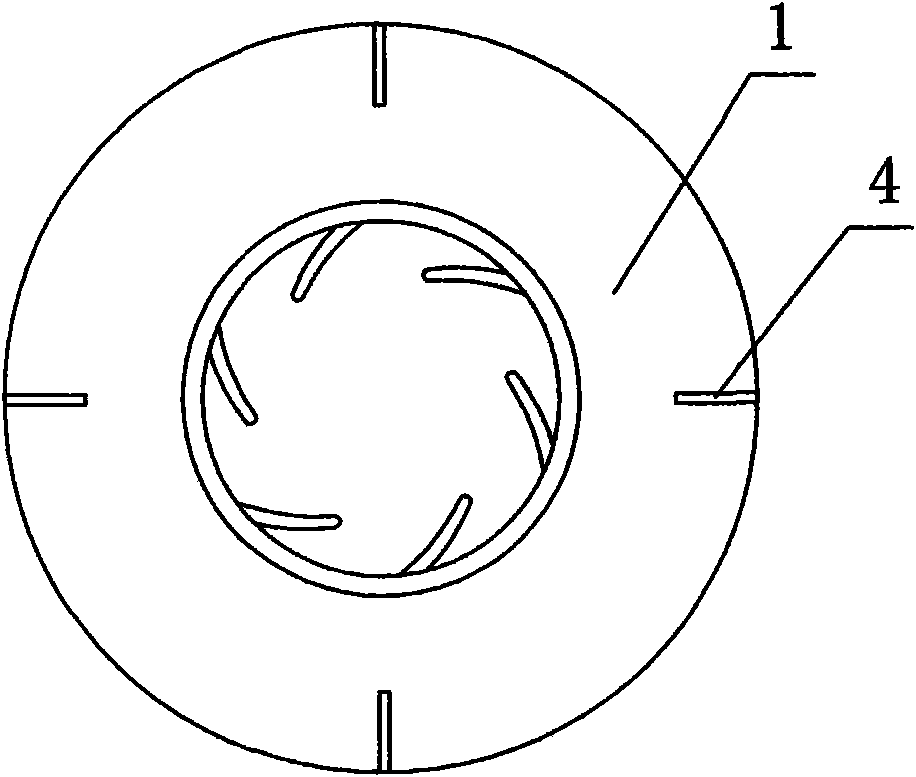

[0013] Such as figure 1 , figure 2 The impeller of an external mixing self-priming pump is shown, the impeller is provided with a front cover 1 and a rear cover 2, a blade 3 is arranged between the front cover 1 and the rear cover 2, and the gas-liquid is evenly distributed on the outside of the cover As can be seen from the figure, the gas-liquid mixing sheet 4 is evenly distributed on the outside of the front cover plate 1. When the pump is initially working, the pump body has strong agitation, good gas-liquid mixing, short gas discharge time and high efficiency.

Embodiment 2

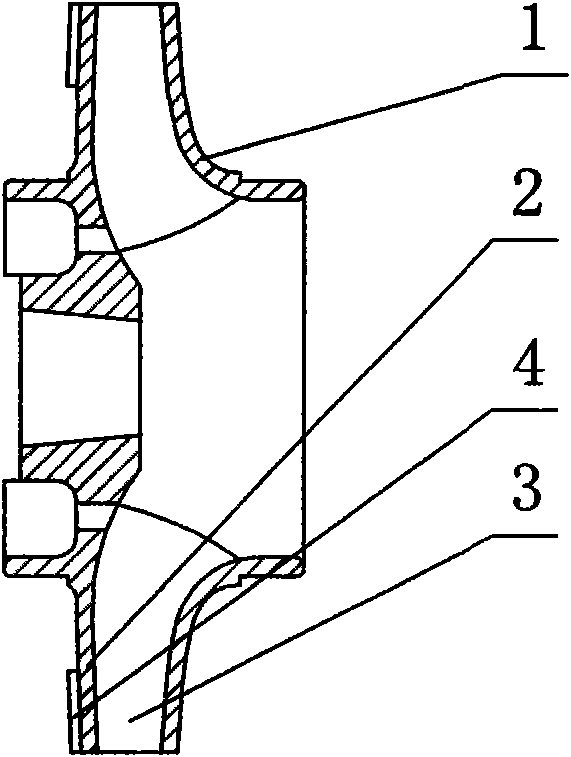

[0015] Such as image 3 , Figure 4 The impeller of an external mixing self-priming pump is shown, the impeller is provided with a front cover 1 and a rear cover 2, a blade 3 is arranged between the front cover 1 and the rear cover 2, and the gas-liquid is evenly distributed on the outside of the cover As for the mixing sheet, it can be seen from the figure that the gas-liquid mixing sheet 4 is evenly distributed on the outside of the rear cover 2 .

Embodiment 3

[0017] Such as Figure 5 , figure 2 , Figure 4 The impeller of an external mixing self-priming pump is shown, the impeller is provided with a front cover 1 and a rear cover 2, a blade 3 is arranged between the front cover 1 and the rear cover 2, and the gas-liquid is evenly distributed on the outside of the cover As for the mixing sheet, it can be seen from the figure that the gas-liquid mixing sheet 4 is uniformly distributed on the outside of the front cover 1 and the rear cover 2 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com