Heating stirrer for low viscous reagents

A heating and stirring technology with low viscosity, applied in the chemical field, can solve the problems of long test cycle, deviation of test results, and difficulty in meeting the test detection of large-capacity liquids, so as to improve the stirring efficiency, reduce the weight and shorten the stirring time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

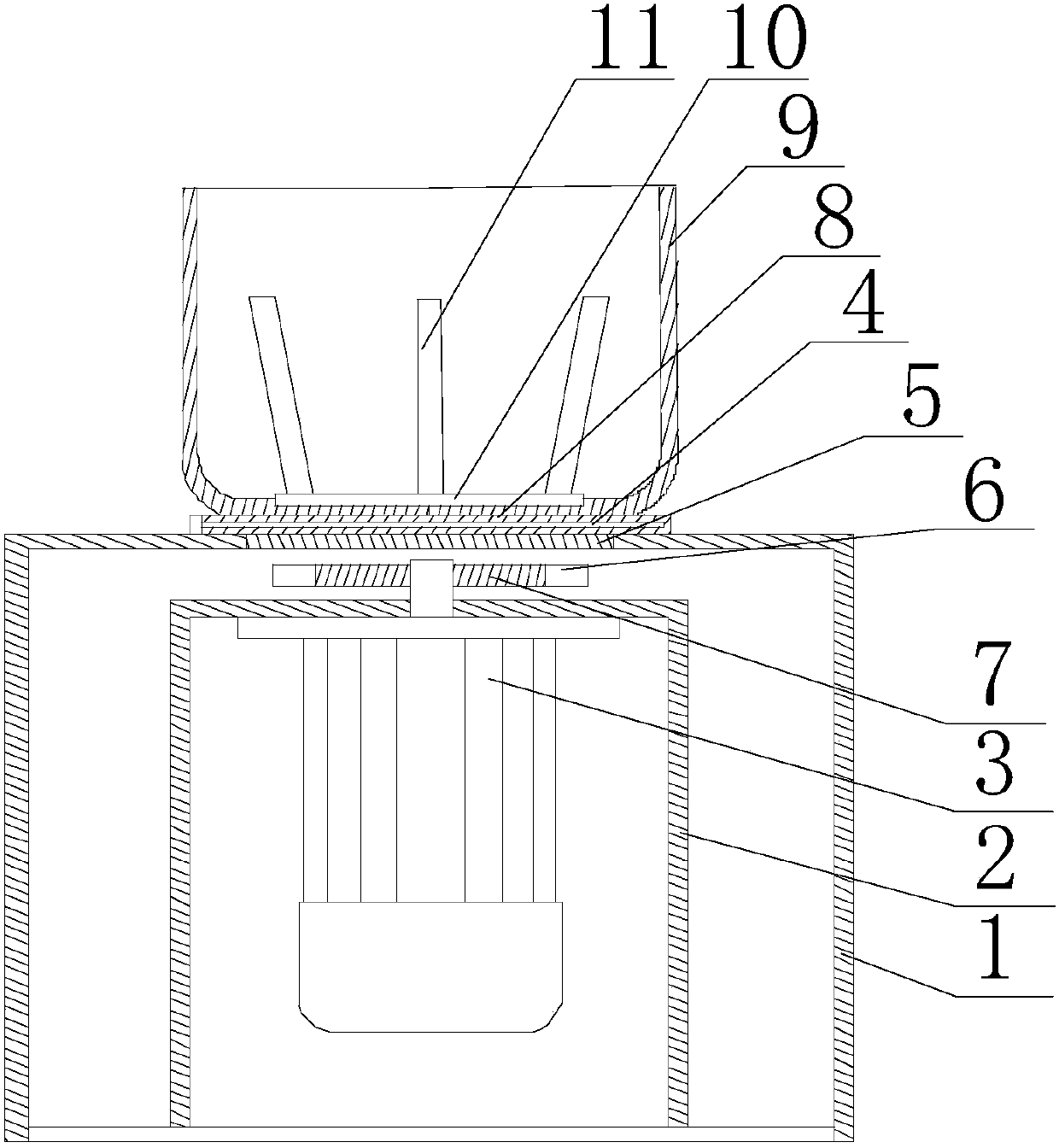

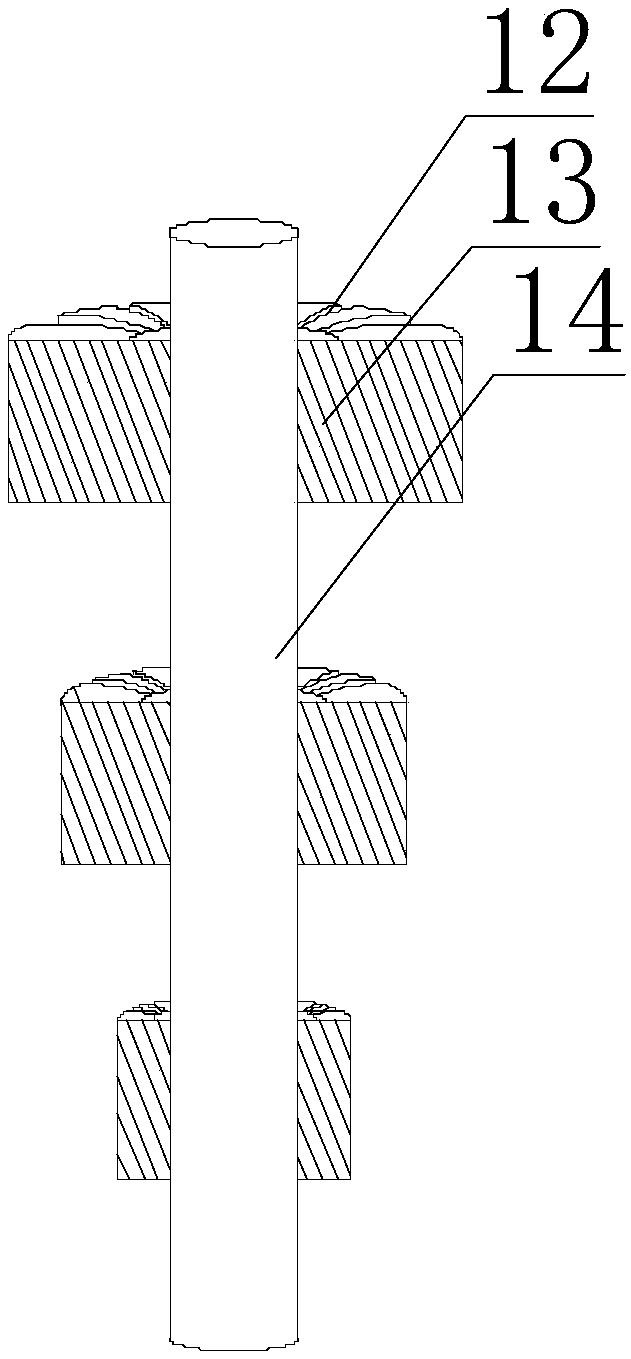

[0021] Such as Figure 1~2 As shown, the present embodiment includes a support base 1 and an installation base 2 arranged inside the support base 1, a motor 3 is arranged inside the installation base 2, an opening is provided on the upper end surface of the installation base 2, and the output end of the motor 3 moves through the The opening extends to the inside of the support seat 1, and a turntable 7 is installed on the extension of the output end of the motor 3, and a plurality of magnetic strips 6 are arranged on the upper end surface of the turntable 7 along the circumference of the turntable 7. On the support seat 1 The upper end surface is provided with a through hole, the turntable 7 is placed between the through hole and the opening, a heat conduction plate 8 is arranged at the upper end of the through hole, and a non-magnetic heat shield 5 is arranged at the lower end of the through hole, and in the heat conduction plate 8 A plurality of heating pipes 4 are provided,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com