Normal-pressure leaching method for high-grade nickel matte and nickel sulfate

A leaching, atmospheric pressure technology, applied in the direction of nickel sulfate, process efficiency improvement, etc., can solve the problems of high oxidant consumption, high manufacturing cost, large equipment volume, etc., to improve mass transfer efficiency, leaching process safety, and improve leaching. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

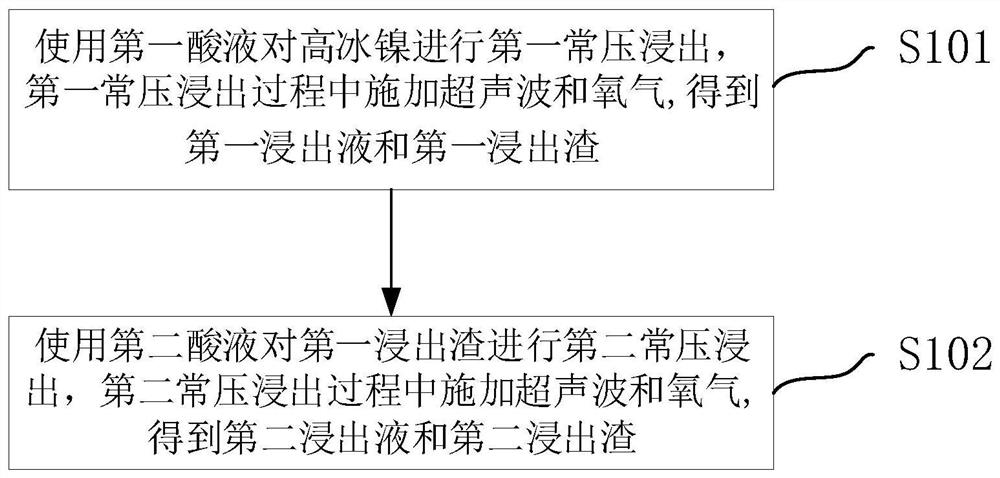

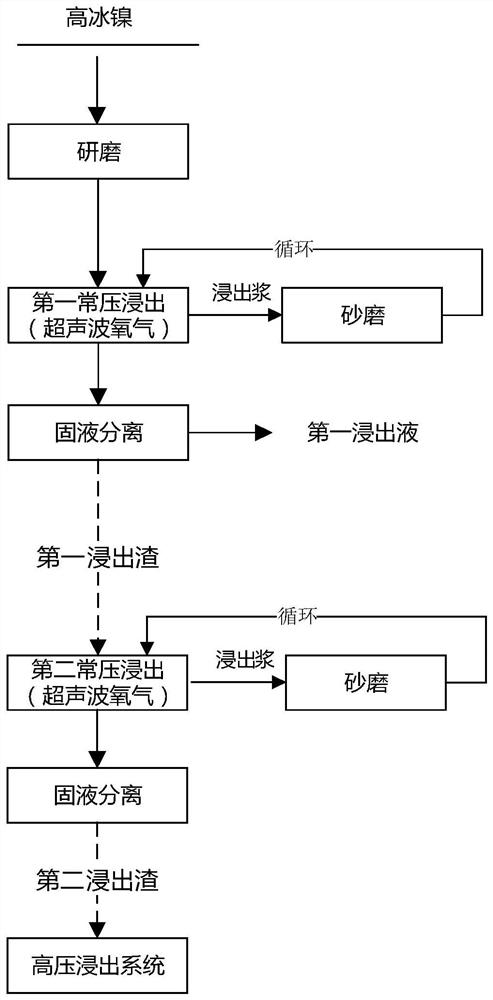

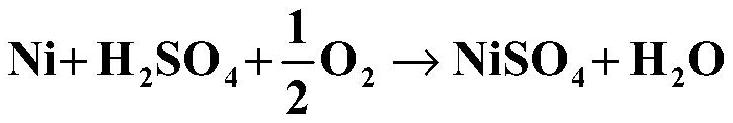

Method used

Image

Examples

Embodiment 1

[0067] Grinding: Grind 5 kg of high nickel matte (purchased from Jilin Jien Nickel Industry Co., Ltd.) to 150 mesh with a ball mill. The test results of high nickel matte are shown in Table 1.

[0068] Table 1 Detection results of high nickel matte composition

[0069] Co% Mn% Ni% Cu% Fe% Al% 1.17 0.0028 60.29 12.59 3.28 0.0005 Ca% Mg% As% S% Zn% h 2 O%

0.0014 0.0011 0.055 12.53 0.0003 0.93

[0070] The first normal pressure leaching: after grinding, high nickel matte is slurried with water according to the ratio of high nickel matte mass (kg) to water volume (L) as 1:8 (water 40L), and concentrated sulfuric acid is added after slurrying to control the leaching pH value Maintained at 1.0, the leaching tank is supplemented by ultrasonic oxygen leaching. During the period, the leaching slurry in the leaching tank passes through the sanding equipment and returns to the leaching tank for continuous cycle leaching. The ultr...

Embodiment 2

[0074] The difference with embodiment 1 only lies in:

[0075] The first normal pressure leaching: after grinding, high nickel matte is slurried with water according to the ratio of high nickel matte mass (kg) to water volume (L) as 1:6 (water 30L), and concentrated sulfuric acid is added after slurrying to control the leaching pH value Maintained at 1.2, the leaching tank is supplemented by ultrasonic oxygen leaching, during which the leaching slurry in the leaching tank passes through the sanding equipment and then returns to the leaching tank for continuous cycle leaching, the ultrasonic frequency is 50kHz, and the flux of oxygen is 20m 3 / (h*ton of dry material), oxygen concentration 88%, solid-liquid separation after leaching for 9 hours to obtain the first leaching liquid and the first leaching slag, the slag contains nickel after accounting, the leaching rate of nickel after the first normal pressure leaching reaches 53.29% .

[0076] The second atmospheric pressure le...

Embodiment 3

[0079] The difference with embodiment 1 is:

[0080] The first atmospheric pressure leaching: after grinding, high nickel matte is slurried with water according to the ratio of high nickel matte mass (kg) to water volume (L) as 1:10 (water 50L), and concentrated sulfuric acid is added after slurrying to control the leaching pH value Maintained at 0.5, the leaching tank is supplemented by ultrasonic oxygen leaching, during which the leaching slurry in the leaching tank returns to the leaching tank after passing through the sand grinding equipment, continuous cycle leaching, ultrasonic frequency 80kHz, oxygen flux 50m 3 / (h*t dry material), oxygen concentration 95%, solid-liquid separation after leaching for 6 hours to obtain the first leaching liquid and the first leaching slag, the slag contains nickel after accounting, the leaching rate of nickel after the first normal pressure leaching reaches 55.52% .

[0081] The second atmospheric pressure leaching: the first leaching sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com