Method for efficiently leaching lithium from lithium-containing clay rock

A clay rock, high-efficiency technology, applied in the field of lithium-containing clay rock high-efficiency leaching of lithium, can solve the problem of less research on the development and utilization of lithium-containing clay rock, and achieve the effect of reducing leaching costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

[0039] The original ore is a lithium-bearing chlorite-type altered residual carbonate rock in Guizhou, the main components of which are CaO and SiO 2 and Al 2 o 3 , the available valuable component is Li 2 O, with a content of 0.46%, the ore is an altered residual structure with a massive structure. The main components are calcite, quartz and clay minerals, and lithium mainly exists in lithium chlorite. The chemical analysis of the main elements of the ore is shown in Table 2.

[0040] element / % Li 2 o

SiO 2

K 2 o

Na 2 o

MnO 2

TiO 2

content 0.46 40.96 1.29 0.11 0.02 0.62 element al 2 o 3

Fe 2 o 3

CaO MgO TS P 2 o 5

content / % 17.98 5.11 13.08 1.13 3.30 0.07

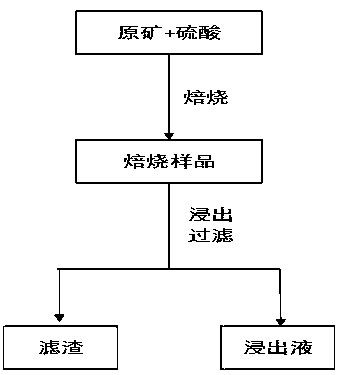

[0041] Process flow chart see figure 1 As shown, the steps are as follows:

[0042] (1) Crushing the raw ore to -2mm;

[0043] (2) Add the crushed raw ore to a rod mill for grinding, and the grinding fineness i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com