Method for reduction leaching of manganese oxide ore through cassava starch

A technology of cassava starch and manganese oxide ore is applied in the field of manganese metallurgy to achieve high efficiency, high manganese leaching rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

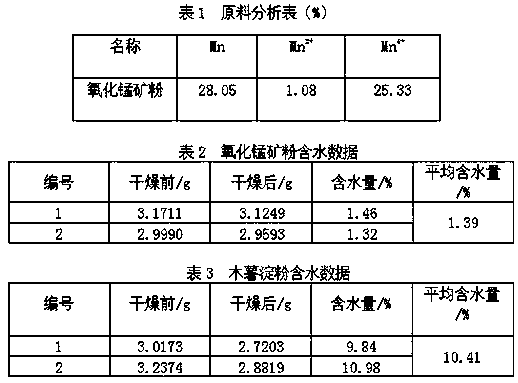

[0019] A method for reducing and leaching manganese oxide ore utilizing tapioca starch, comprising the steps of:

[0020] (1) Take concentrated sulfuric acid (A.R) and ammonium sulfate (A.R) to prepare a mixed solution with an initial acidity of 200g / L and an ammonium sulfate concentration of 100g / L, heat the mixed solution to 85°C, add tapioca starch, and The acid hydrolysis reaction was carried out under stirring at 85°C; the acid hydrolysis time was 2.5 hours; the amount of tapioca starch was based on tapioca starch: Mn in manganese oxide ore 4+ The mass ratio of the content is added in a ratio of 0.35;

[0021] (2) Grind the manganese oxide ore to 50 mesh to obtain manganese oxide ore powder. After the acid hydrolysis, add manganese oxide ore powder to the solution to control the liquid-solid mass ratio of the ore slurry to 8:1; leaching and stirring at 80°C for 3 hours , after the reaction, the manganese sulfate leaching solution was obtained by filtration and separation...

Embodiment 2

[0024] A method for reducing and leaching manganese oxide ore utilizing tapioca starch, comprising the steps of:

[0025] (1) Take concentrated sulfuric acid and ammonium sulfate to prepare a mixed solution with an initial acidity of 200g / L and an ammonium sulfate concentration of 100g / L, heat the mixed solution to 90°C, add tapioca starch, and carry out at 90°C under stirring Acid hydrolysis reaction; acid hydrolysis time 2 hours; the consumption of tapioca starch is according to tapioca starch: Mn in manganese oxide ore 4+ The mass ratio of the content is added in a ratio of 0.40;

[0026] (2) Grind manganese oxide ore to 100 mesh to obtain manganese oxide ore powder. After acid hydrolysis, add manganese oxide ore powder to the solution to control the liquid-solid mass ratio of ore slurry to 9:1; leaching and stirring at 90°C for 2.5 hours , after the reaction, the manganese sulfate leaching solution was obtained by filtration and separation; the leaching rate of manganese ...

Embodiment 3

[0028] A method for reducing and leaching manganese oxide ore utilizing tapioca starch, comprising the steps of:

[0029] (1) Take concentrated sulfuric acid and ammonium sulfate to prepare a mixed solution with an initial acidity of 200g / L and an ammonium sulfate concentration of 100g / L, heat the mixed solution to 95°C, add tapioca starch, and carry out at 95°C under stirring Acid hydrolysis reaction; acid hydrolysis time 1.5 hours; the amount of tapioca starch is according to tapioca starch: Mn in manganese oxide ore 4+ The mass ratio of the content is added in a ratio of 0.41;

[0030](2) Crush the manganese oxide ore to more than 50 meshes to obtain manganese oxide ore powder. After the acid hydrolysis, add manganese oxide ore powder into the solution to control the liquid-solid mass ratio of the slurry to 10:1; leaching and stirring at 95°C for reaction 2 hour, after the reaction was finished, the manganese sulfate leaching solution was obtained by filtration and separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com