Food waste hydrolysis and spray explosion system

A technology of food waste and spray explosion tank, which is applied in the field of hydrolysis spray explosion treatment of food waste and food waste hydrolysis spray explosion system, can solve the problems of slow reaction, pyrolysis reaction, waste, etc., and achieve reaction balance and material Uniform distribution and full contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

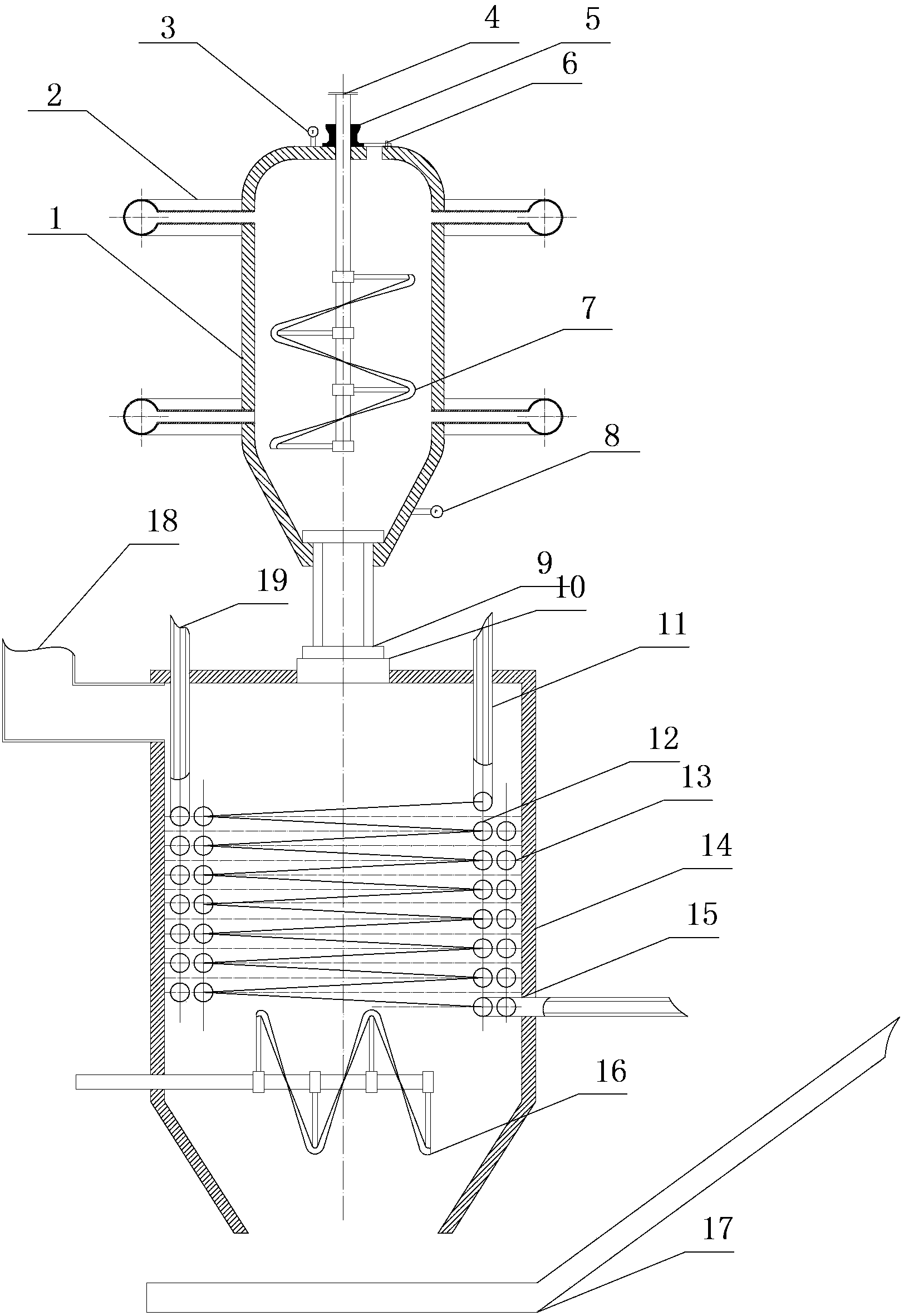

[0025] see Figure 1 to Figure 3 As shown, a food waste hydrolysis detonation system of the present invention includes a detonation tank and a detonation chamber arranged under the detonation tank.

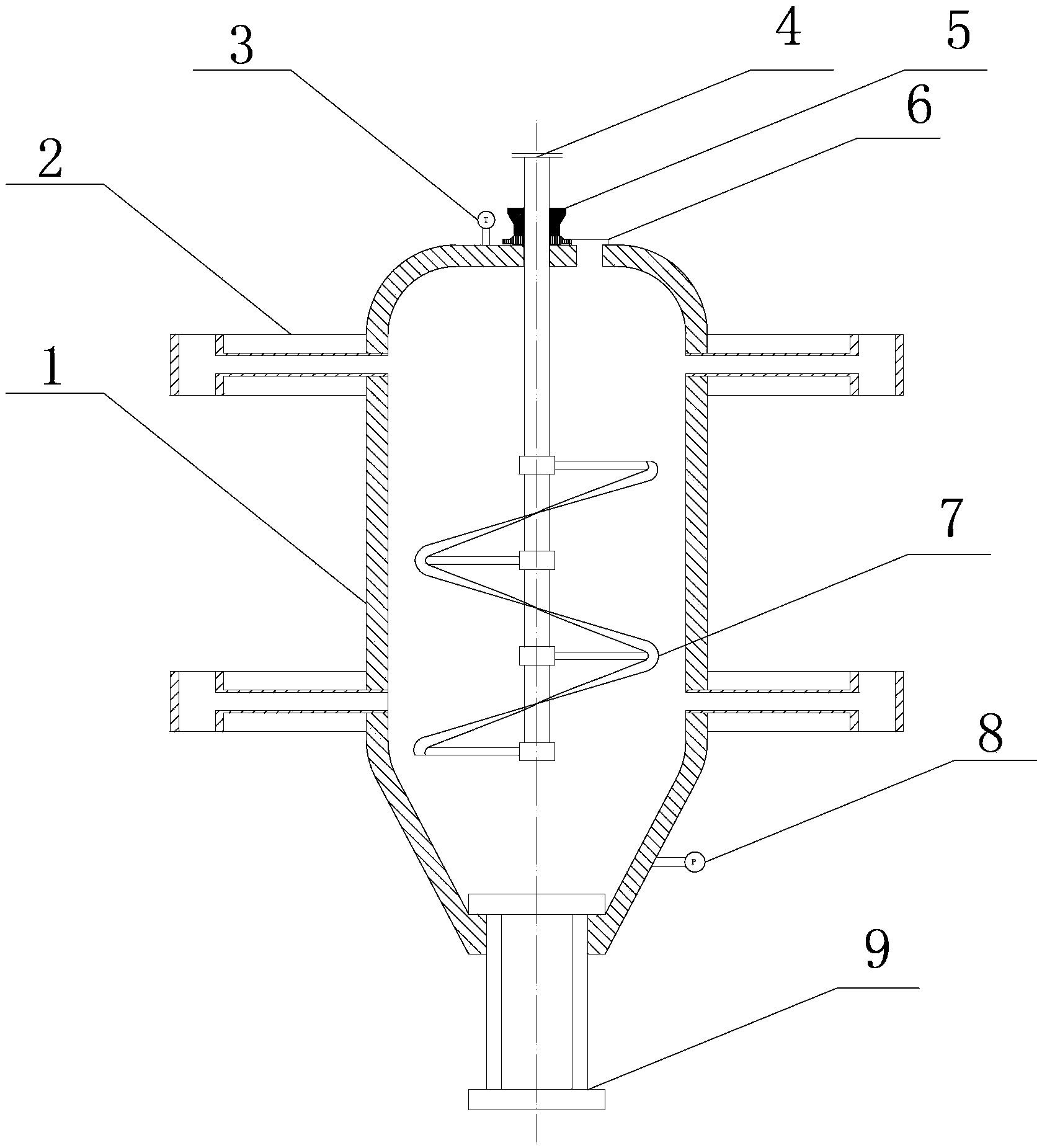

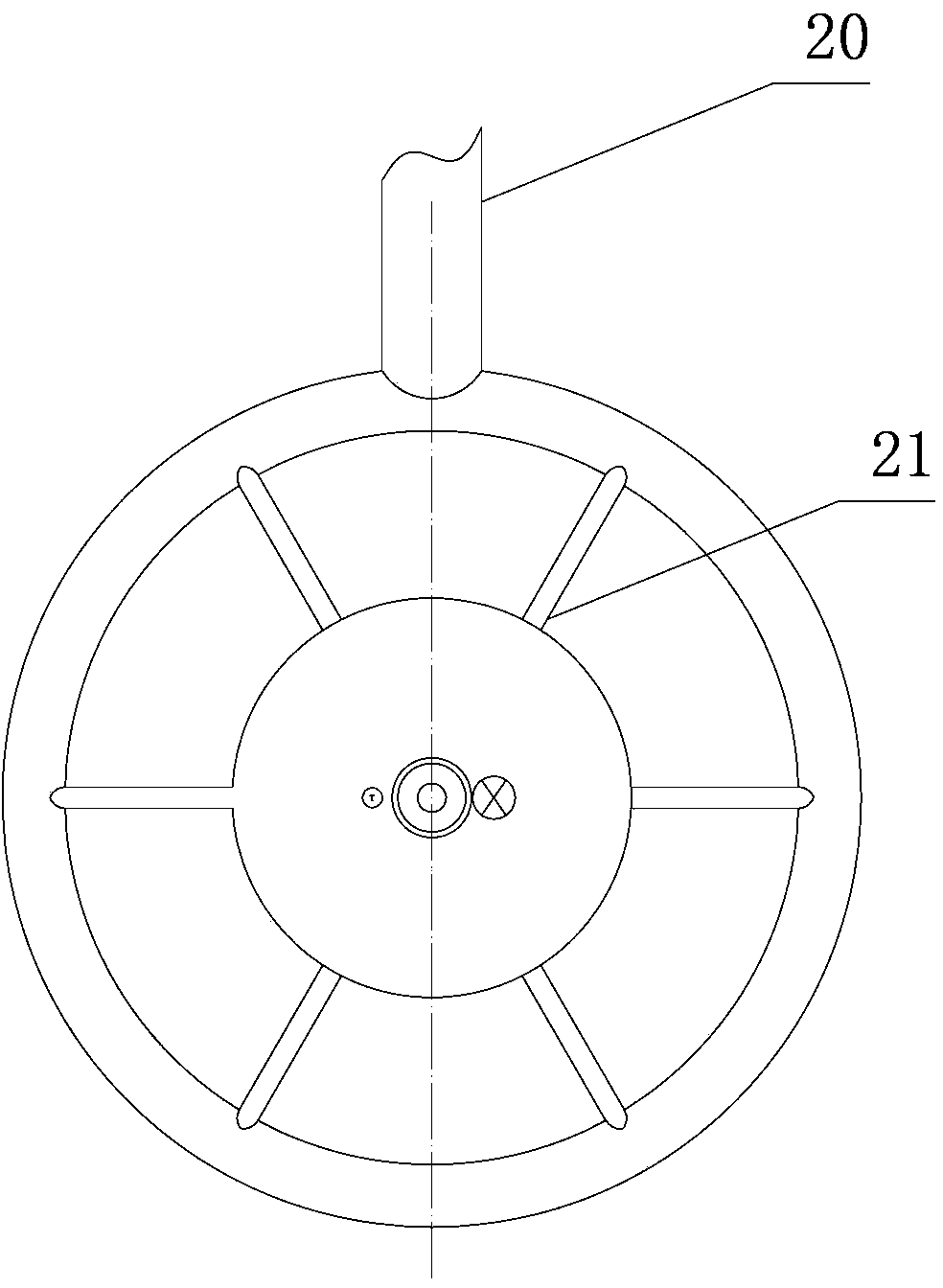

[0026] The spray explosion tank includes a spray explosion tank shell 1. The top of the spray explosion tank shell 1 is provided with a feed port 6, a thermometer 3 and a mechanical seal device 5. The agitator shaft 4 penetrates the mechanical seal device 5 and extends into the spray explosion tank shell. 1, the agitator shaft 4 is provided with a first ribbon agitator 7; the side wall of the spray tank housing 1 is provided with two annular air inlet devices 2, and the annular air inlet device 2 includes a connecting external air inlet pipe 20 An annular ring, the annular ring communicates with the explosion tank shell 1 through six evenly distributed steam passages 21; the bottom of the explosion tank shell 1 is provided with a pressure gauge 8 and a discharge port 9.

[0027] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com