Vanadium-nitrogen additive for smelting microalloyed steel and method for preparing same

A micro-alloying and additive technology, applied in the field of metallurgical auxiliary materials, can solve the problem of vanadium element strengthening effect not being exerted, and achieve the effects of improving the metallurgical reaction speed, increasing the reaction area and stabilizing the recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

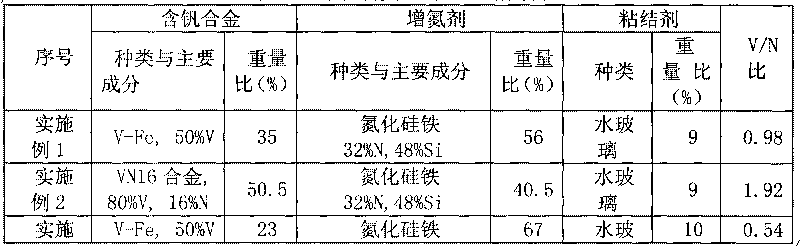

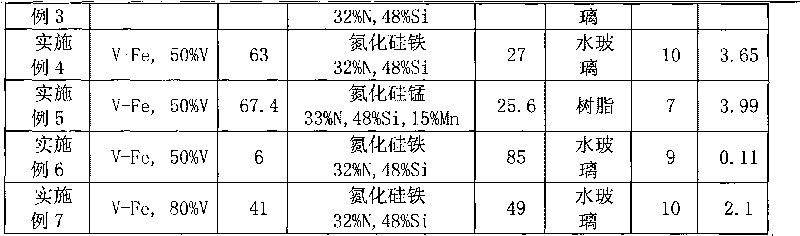

[0012] The vanadium-nitrogen additive of the present invention is a composition uniformly mixed together by vanadium-containing alloy powder, nitrogen-enhancing agent powder and binder, wherein the weight ratio of the binder is 5-12%, and the vanadium alloy powder and nitrogen-increasing The weight ratio of the agent powder is 88-95%, and the V / N ratio is controlled at 0.1-4.

[0013] Vanadium-containing alloy powders are: vanadium-iron powder, vanadium-nitrogen alloy powder;

[0014] Nitriding agent powder is: silicon nitride powder, silicon manganese nitride powder, ferrosilicon nitride powder, ferromanganese nitride powder;

[0015] Binders are: water glass, asphalt, resin, phosphate.

[0016] In order to ensure that the V / N ratio is controlled at 0.1 to 4, the weight ratio of the vanadium-containing alloy powder to the nitrogen-enhancing agent powder can be determined as follows:

[0017] Assuming that the weight ratio of vanadium-containing alloy powder is X%, the weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com