Zinc-nickel secondary cell and preparation method thereof

A secondary battery, zinc-nickel technology, applied in nickel storage battery, alkaline storage battery manufacturing, alkaline storage battery and other directions, can solve the problems of difficult quality control of γ-nickel oxyhydroxide, complex production process, poor high current discharge performance, etc. , to achieve the effect of improving high-current discharge performance, easy quality control, and stable electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

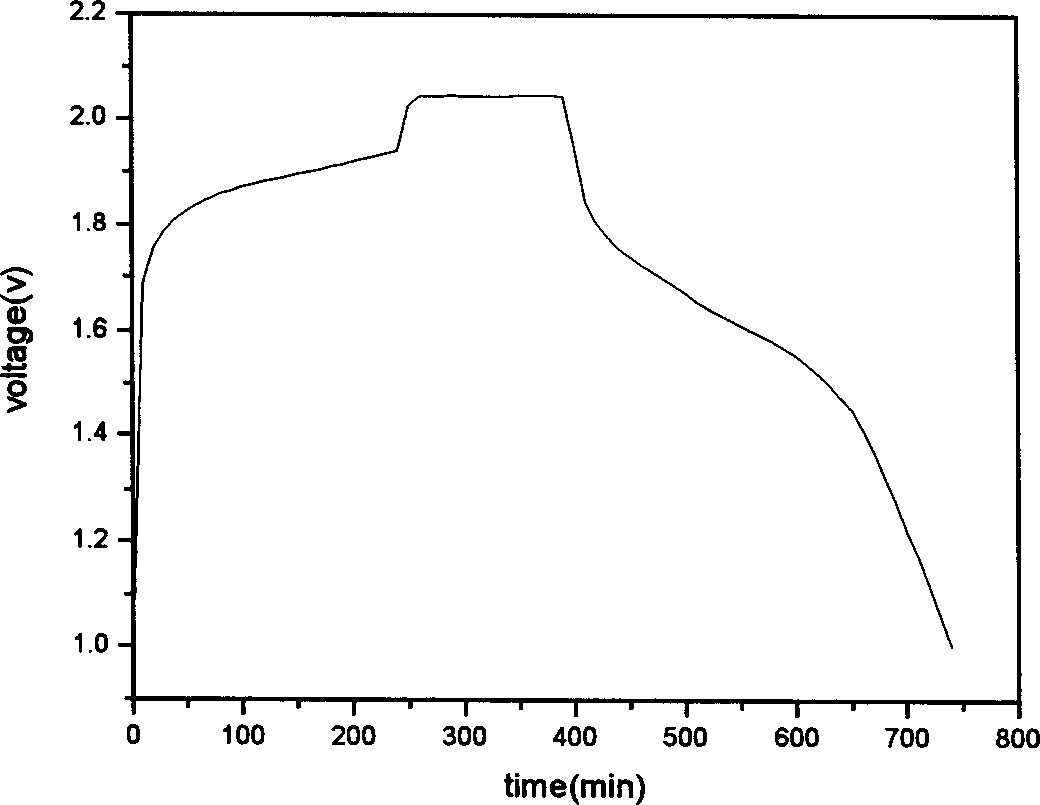

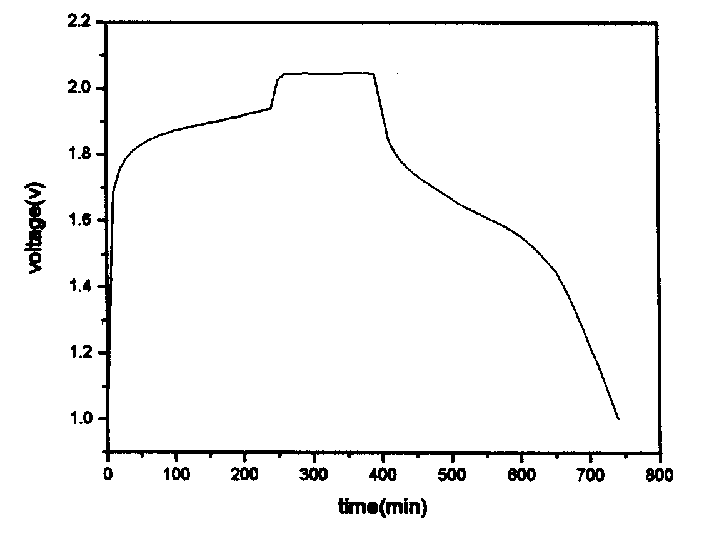

Image

Examples

Embodiment 1

[0059] A piece of nickel strip with a cutting size of 40×100mm and a thickness of 0.25mm is used as the conductive substrate of the positive electrode, and a conductive terminal is spot-welded therein. 70% by weight of ordinary nickel hydroxide powder and 27% by weight of conductive additive graphite powder are evenly mixed. The PVA binder that is 3% by weight is dissolved in water first, and then mixed with the above-mentioned mixture and water to form a positive electrode slurry, coated on a nickel belt, and dried in an oven at 100 ° C. The cleanness of the positive electrode slurry The dry gain weight is controlled at 8±0.1g, and the nickel strip positive electrode sheet is rolled to a thickness of 0.50mm with a double rolling mill with a diameter of 400mm, and immersed in an aqueous sodium hydroxide solution with a concentration of 14M (which also contains lithium hydroxide 40g / l) in the electrolyzer.

[0060] The nickel hydroxide in the formed positive electrode sheet is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com