Nano metal oxide/MXene heterostructure composite material and preparation method thereof

A nano-metal and heterostructure technology, applied in nanotechnology, structural parts, nanotechnology, etc., can solve the problems of serious MXene agglomeration, oxidative deterioration of MXene, and complicated preparation process, so as to increase the reactive area and improve the utilization rate , various effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

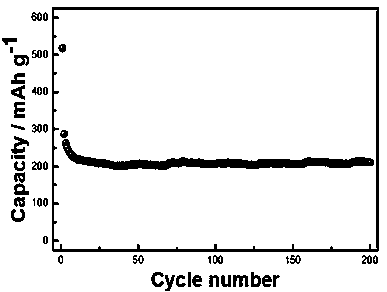

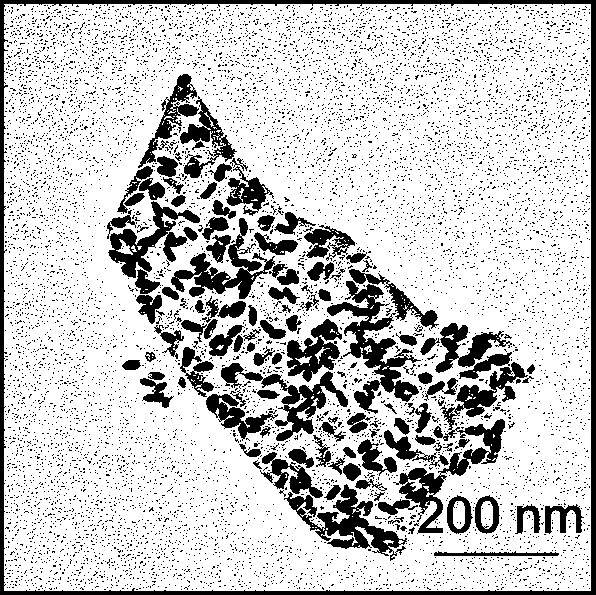

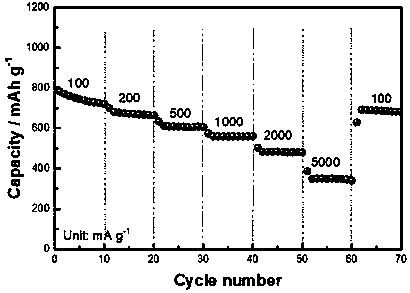

Embodiment 1

[0039] (1) Synthesis of MXenes

[0040] Add 0.99g LiF into a plastic bottle containing 10ml hydrochloric acid, stir for 5min to dissolve LiF, then add 1 gTi 3 AlC 2 , stir well. The obtained mixed solution was placed in a 35° C. constant temperature water bath, and stirred and etched for 24 hours. After the etching reaction, add water to the above product and centrifuge repeatedly for 4 times until the supernatant is pH ≈ 6, pour off the supernatant, add water again, sonicate for 30 minutes, and centrifuge for 1 hour to collect the upper solution to obtain the etched MXene solution;

[0041] Measure 5ml of the MXene solution, filter it with suction, dry it and weigh it to obtain a MXene concentration of 2.6mg / ml, and dilute the prepared MXene aqueous solution to 1 mg / ml;

[0042] (2) Synthesis of nano-metal oxide / MXene heterostructure composites

[0043] Take 70mg nanorod TiO 2 In a 500ml Erlenmeyer flask, add 500ml NMP, ultrasonically disperse for 1h,

[0044] Measure 2...

Embodiment 2

[0050] (1) Synthesis of MXenes

[0051] Add 0.99g LiF into a plastic bottle containing 10ml hydrochloric acid, stir for 5min to dissolve LiF, then add 1 gTi 3 AlC 2 , stir well. Put the obtained mixture into a 35°C constant temperature water bath, stir

[0052] Etching 24h. After the etching reaction, add water to the above product and centrifuge repeatedly for 4 times until the supernatant pH ≈ 6, pour off the supernatant, add water again, sonicate for 30 minutes, centrifuge for 1 hour, collect the upper solution, and obtain the etched MXene solution;

[0053] Measure 5ml of the MXene solution, filter it with suction, dry it and weigh it to obtain a MXene concentration of 2.6 mg / ml, and dilute the prepared MXene aqueous solution to 2 mg / ml;

[0054] (2) Synthesis of nano-metal oxide / MXene heterostructure composites

[0055] Take 70mg nanowire SnO 2 In a 500ml Erlenmeyer flask, add 500ml DMF, sonicate for 1h,

[0056] Measure 15ml of MXene aqueous solution, drop by drop...

Embodiment 3

[0062] (1) Synthesis of MXenes

[0063] Add 0.99g LiF into a plastic bottle containing 10ml hydrochloric acid, stir for 5min to dissolve LiF, then add 1 gTi 3 AlC 2 , stir well. The obtained mixed solution was placed in a 35° C. constant temperature water bath, and stirred and etched for 24 hours. After the etching reaction, add water to the above product and centrifuge repeatedly for 4 times until the supernatant pH ≈ 6, pour off the supernatant, add water again, sonicate for 30 minutes, centrifuge for 1 hour, collect the upper solution, and obtain the etched MXene solution;

[0064] Measure 5ml of the MXene solution, filter it with suction, dry it and weigh it to obtain a MXene concentration of 2.6mg / ml, and dilute the prepared MXene aqueous solution to 1 mg / ml;

[0065] (1) Synthesis of nano-metal oxide / MXene heterostructure composites

[0066] Take 70mg Fe 3 o 4 Put quantum dots in a 500ml Erlenmeyer flask, add 500ml THF, ultrasonically disperse for 1h,

[0067] Mea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com