Preparation method for ordered ultra-thin catalyst layer, catalyst layer and application

An ultra-thin catalytic layer and catalytic layer technology, applied in electrical components, battery electrodes, circuits, etc., to increase the three-phase reaction area, improve utilization, and reduce mass transfer resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

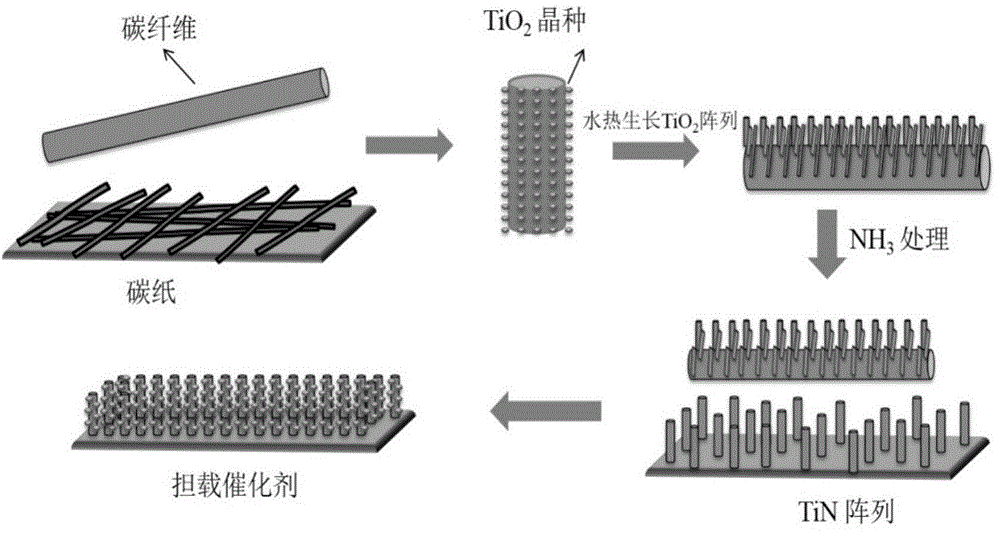

[0026] Immerse one side of the carbon paper substrate in 0.05M-0.2M TiCl 4 Surface of aqueous solution, annealed in air at 350°C to obtain TiO 2 Seed.

[0027] Will get with TiO 2 The seeded carbon paper was immersed in a mixture of 1.1mL butyl titanate, 37mL concentrated hydrochloric acid with a mass fraction of 38%, and 37mL deionized water, and reacted at 150°C for 10h.

[0028] Will get TiO 2 Array with NH 3 For etching, NH 3 The flow rate is 60mL / cm 2 , the temperature was 850°C, and the reaction time was 4h to obtain a TiN array.

[0029] The PtPdCo alloy catalyst was loaded on the surface of the TiN array by magnetron sputtering (under Ar atmosphere at 20°C, sputtering power 200W, vacuum degree 1.0Pa, sputtering time Pt: 12min, Pd: 7min, Co: 15min) ( Atomic ratio Pt:Pd:Co=1:0.96:0.090, where Pt: 66.95μg / cm 2 ,Pd:35.115μg / cm 2,Co:1.83μg / cm 2 ), to obtain an ordered ultrathin catalytic layer.

[0030] figure 1 is a flow chart of the preparation process, figu...

Embodiment 2

[0034] Take the TiN nanorod array prepared in Example 1.

[0035] Apply electrodeposition technology (pulse electrodeposition technology is used here) to load Pt catalyst on the surface of TiN array, and the reaction solution is: 0.2mM H 2 PtCl 6 , the supporting electrolyte is 1mol HCl, 150mL. Pulse electrodeposition parameters: jp=-40mA / cm 2 , Ton=0.3ms, Toff=0.7ms, pulse time 5min.

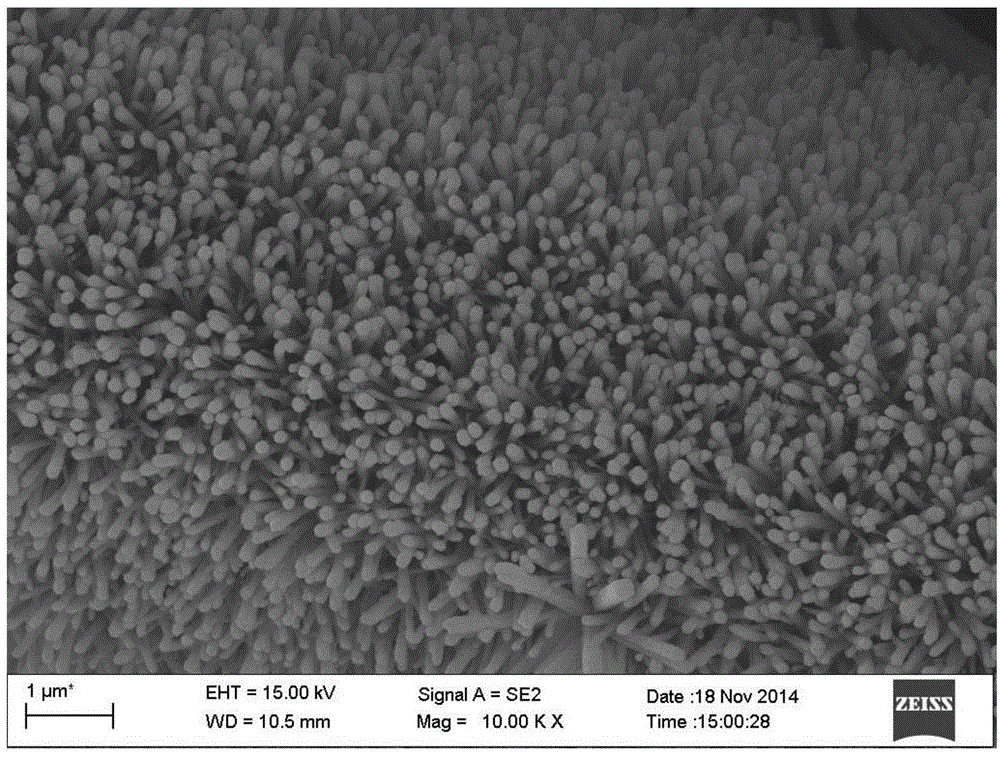

[0036] Figure 4 is the FESEM image of the Pt-TiN nanorod array.

Embodiment 3

[0038] Get the TiN nanorod array prepared in Example 1

[0039] Magnetron sputtering (sputtering time Pt: 10min, Pd: 5min, Cu: 5min, other sputtering conditions are the same as embodiment 1) loaded PtPdCu alloy catalyst (atomic ratio Pt:Pd:Cu= 1:1.57:0.35, where Pt:45.375μg / cm 2 ;Pd: 15.775μg / cm 2 ; Cu: 5.245μg / cm 2 ), the ternary alloy is obtained by annealing treatment (the purpose of annealing treatment is to increase the degree of alloying), and an ordered ultra-thin catalytic layer is obtained.

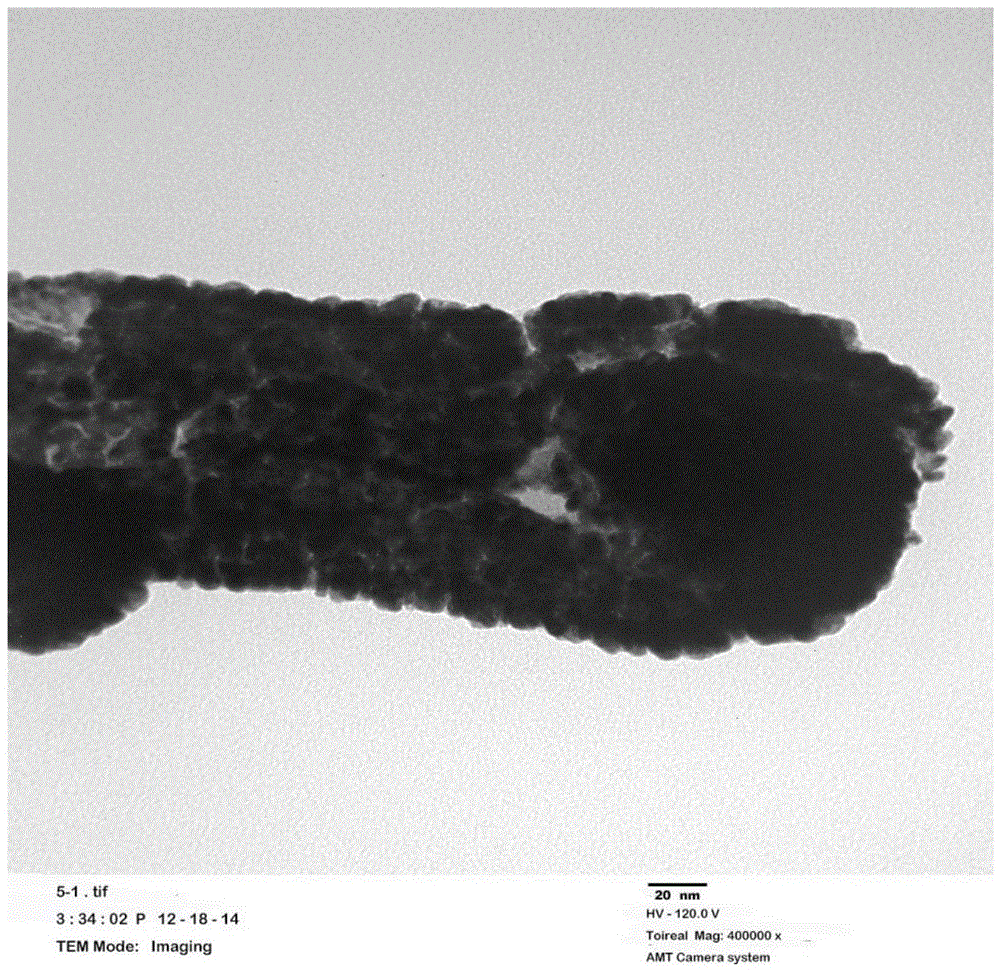

[0040] Figure 5 It is the TEM image of PtPdCu-TiN.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com