Expansible fire retardant having double-layer core-shell structure, and preparation method and application thereof

A technology of intumescent flame retardant and core-shell structure, which is applied in the field of materials, can solve the problems of poor water resistance and compatibility, restrict the comprehensive performance of intumescent flame retardant composite materials, and achieve the effect of good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

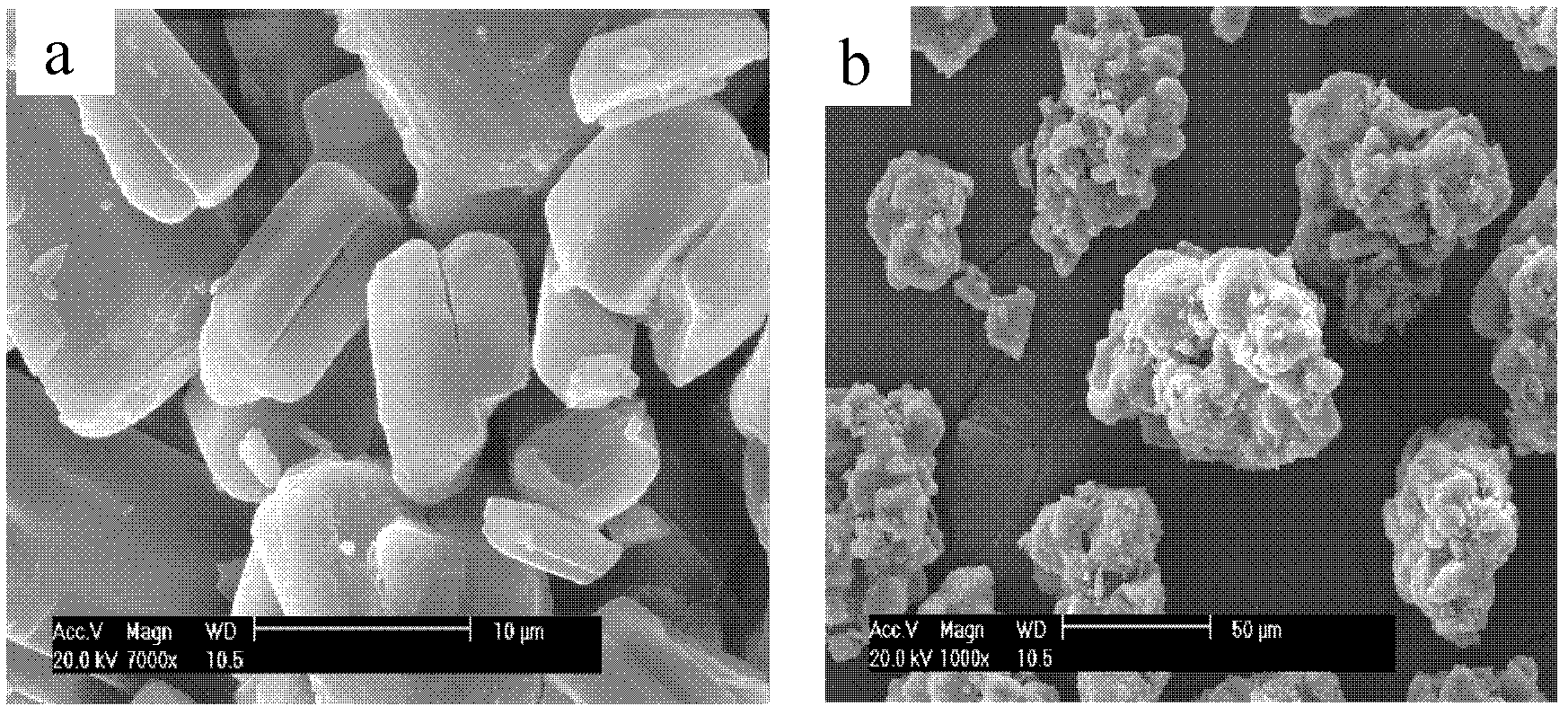

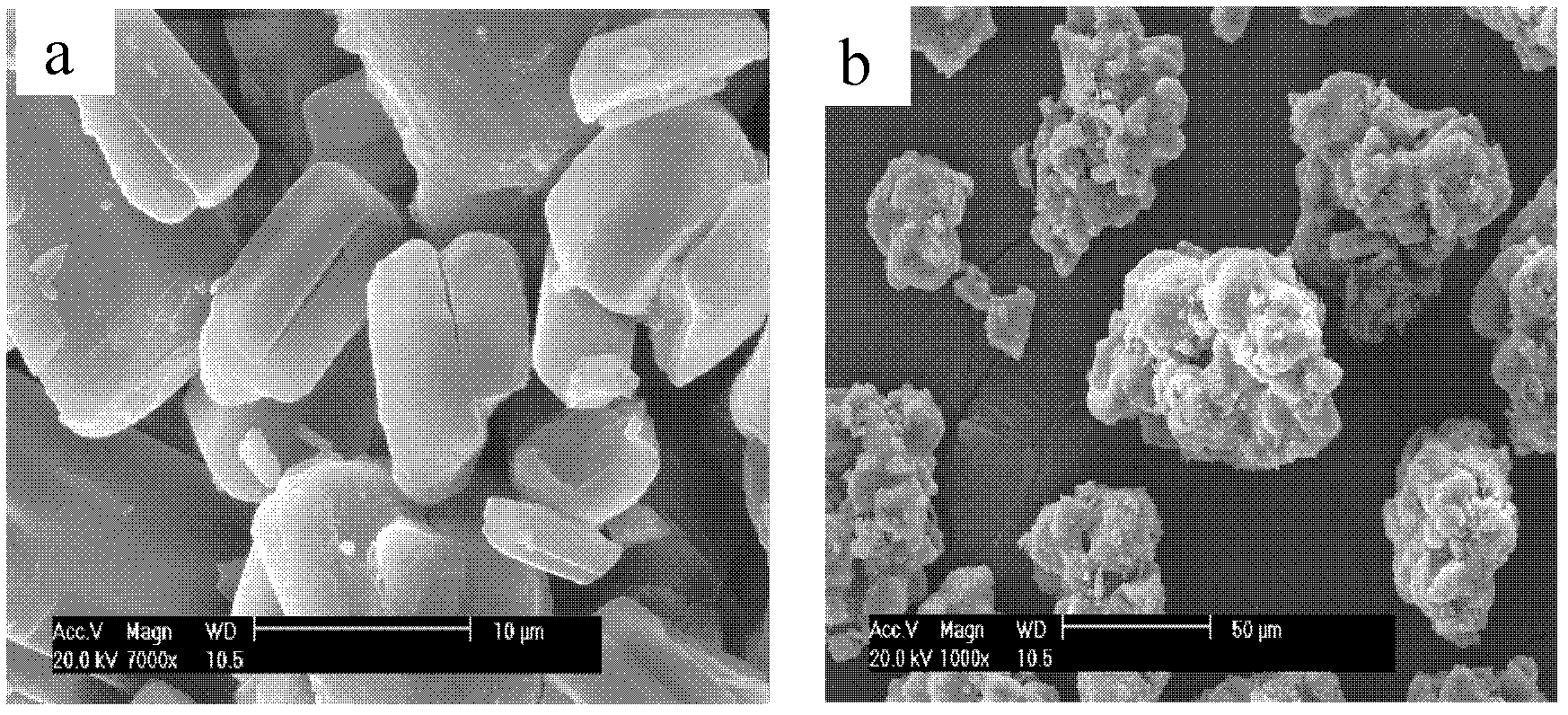

Image

Examples

Embodiment 1

[0037] (1) The preparation of MF prepolymer aqueous solution: add 50ml distilled water in the there-necked flask, 10g melamine, 19 grams of formaldehyde aqueous solution of mass percent 37%, adjustment system pH is 8-9 (0.01 gram Na 2 CO 3 ), stirred and heated up to 80°C, kept warm for half an hour, and then the system was fixed to 100ml with distilled water for use, which was the aqueous solution of melamine-formaldehyde (MF) prepolymer, in which the amount of melamine-formaldehyde prepolymer was 17.03 .

[0038] (2) Preparation of double-layer core-shell structure flame retardant: Add 30 grams of ammonium polyphosphate (APP) into a three-necked flask filled with 80ml of ethanol and stir fully, heat up to 80°C, add 7 grams of epoxy resin (E- 44), until the dispersion is complete, then add the modified aliphatic curing agent-ethanol solution dropwise within 30 minutes (obtained by dissolving 2.7 grams of modified aliphatic curing agent (WK6683, Guangdong Huishun Chemical Co....

Embodiment 2

[0043] (1) The preparation of MF prepolymer aqueous solution: add 50ml distilled water in the there-necked flask, 10g melamine, 19 grams of formaldehyde aqueous solution of mass percent 37%, adjustment system pH is 8-9 (0.01 gram Na 2 CO 3 ), stirring and heating up to 80°C, heat preservation reaction for half an hour, and then use distilled water to make the system 100ml for use, which is a melamine-formaldehyde (MF) prepolymer aqueous solution, wherein the amount of melamine-formaldehyde prepolymer is 17.03g .

[0044] (2) Preparation of double-layer core-shell structure flame retardant: Add 20 grams of ammonium polyphosphate (APP) into a three-necked flask filled with 80ml of ethanol and stir fully, heat up to 80°C, add 7 grams of epoxy resin (E- 44), until the dispersion is complete, then drop the modified aliphatic curing agent-ethanol solution within 30 minutes (dissolve 3.5 grams of modified alicyclic curing agent (1618, Guangzhou Xiupo Chemical Co., Ltd.) in 20ml etha...

Embodiment 3

[0047] (1) Preparation of MF prepolymer aqueous solution: add 50ml of distilled water, 10g of melamine, 19 grams of 37% formaldehyde solution by mass in a three-necked flask, adjust the pH of the system to be 8-9 (0.02 grams of potassium carbonate), stir and heat up to 80 ℃, heat preservation reaction for half an hour, and then use distilled water to prepare the system to 100ml for use, which is a melamine-formaldehyde (MF) prepolymer aqueous solution, wherein the amount of melamine-formaldehyde prepolymer is 17.03g.

[0048] (2) Preparation of double-layer core-shell structure flame retardant: Add 30 grams of ammonium polyphosphate (APP) into a three-necked flask filled with 80ml xylene and stir fully, heat up to 80°C, add 7 grams of epoxy resin (E -44), until the dispersion is complete, then drop m-phenylenediamine-ethanol solution (obtained by dissolving 0.83 g of m-phenylenediamine in 20 ml of ethanol) within 30 minutes, keep stirring and condensing to reflux, keep the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solubility | aaaaa | aaaaa |

| Solubility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com