Mesoporous silicon/cobalt disilicide composite microsphere material as well as preparation method and application thereof

A composite microsphere, disilicide technology, applied in silicon compounds, chemical instruments and methods, nanotechnology for materials and surface science, etc. , SEI film rupture and other problems, to achieve the effect of improving the electrochemical reaction rate, increasing the electrochemical reaction interface, and shortening the charge transfer distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Under stirring conditions, add 20 mL of ammonia solution with a concentration of 4 mol / L and 30 mL of orthosilicic acid with a concentration of 0.5 mol / L to 10 mL of ethanol solution of cobalt nitrate with a concentration of 0.1 mol / L. Ethyl ester in ethanol, at 25 o After reacting at C for 36 h, the precipitate obtained was centrifuged and washed with deionized water, and the precursor powder was obtained after drying;

[0020] (2) Mix the precursor powder and magnesium powder uniformly at a mass ratio of 1:1, place in an argon atmosphere, and heat to 700 o C to make it react and keep it warm for 3 h. After cooling, the product was washed with 2 mol / L hydrochloric acid, and then washed repeatedly with deionized water. After drying, the mesoporous silicon / cobalt disilicide composite microsphere material was obtained.

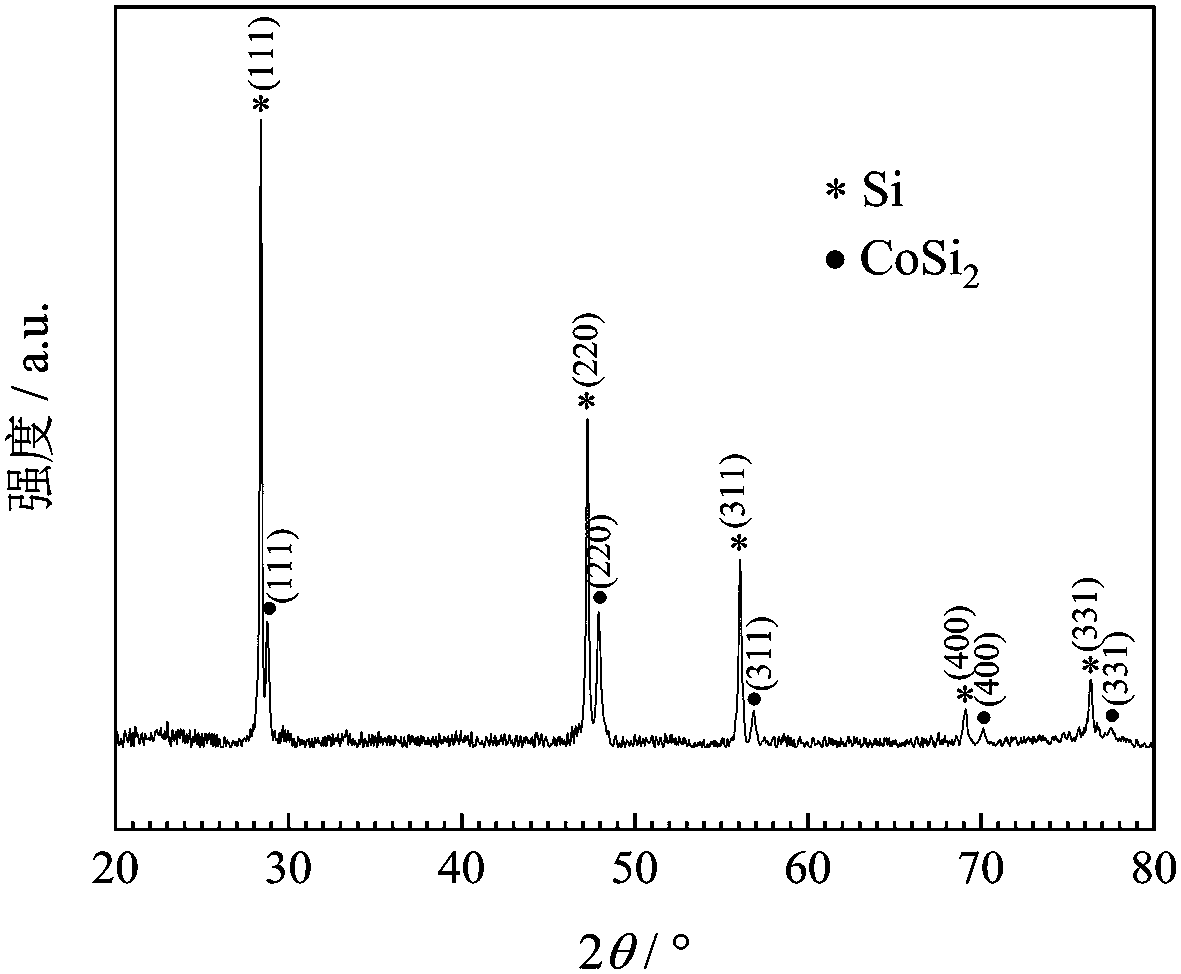

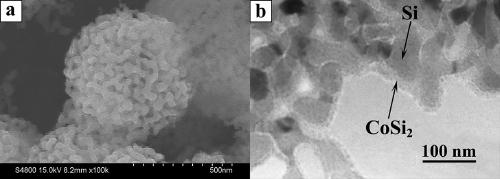

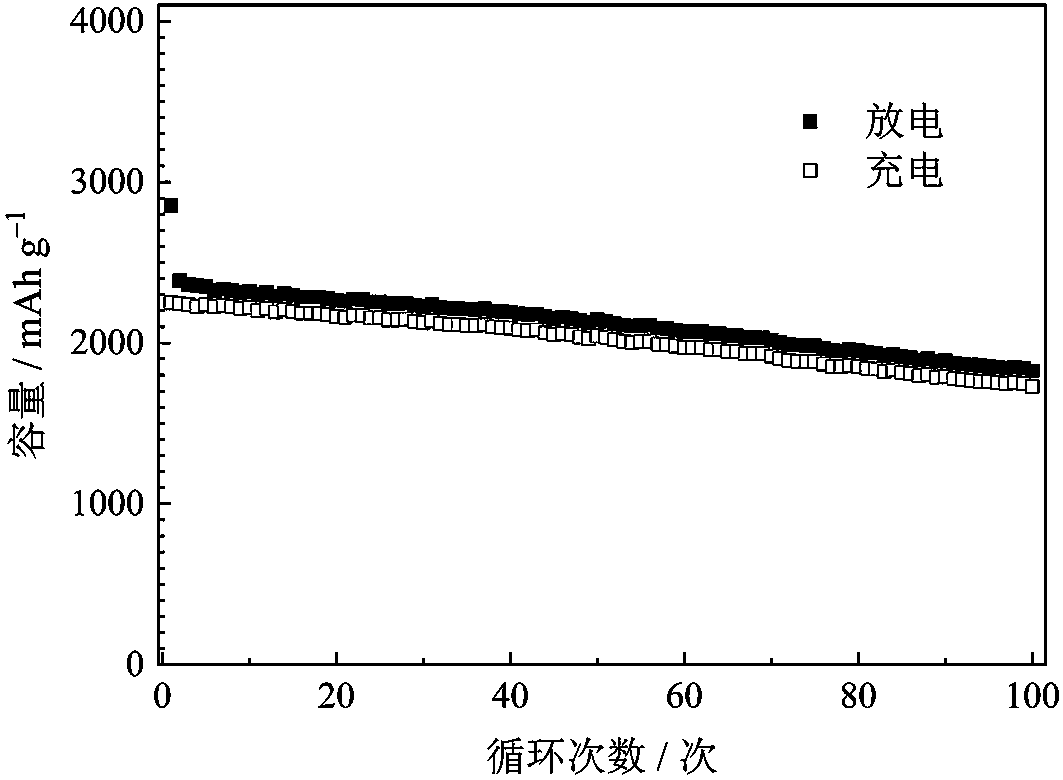

[0021] In the obtained mesoporous silicon / cobalt disilicide composite microsphere material, the massfraction of silicon is 88%, and the massfraction...

Embodiment 2

[0025] (1) Under stirring conditions, add 20 mL of ammonia solution with a concentration of 4 mol / L and 30 mL of orthosilicic acid with a concentration of 0.5 mol / L to 10 mL of ethanol solution of cobalt nitrate with a concentration of 0.05 mol / L. Ethyl ester in ethanol, at 25 o After reacting at C for 36 h, the precipitate obtained was centrifuged and washed with deionized water, and the precursor powder was obtained after drying;

[0026] (2) Mix the precursor powder and magnesium powder uniformly at a mass ratio of 1:1, place in an argon atmosphere, and heat to 700 o C to make it react and keep it warm for 3 h. After cooling, the product was washed with 2 mol / L hydrochloric acid, and then washed repeatedly with deionized water. After drying, the mesoporous silicon / cobalt disilicide composite microsphere material was obtained.

[0027] In the obtained mesoporous silicon / cobalt disilicide composite microsphere material, the mass fraction of silicon is 93%, the mass fraction ...

Embodiment 3

[0031] (1) Under stirring conditions, add 20 mL of ammonia solution with a concentration of 4 mol / L and 30 mL of orthosilicic acid with a concentration of 0.5 mol / L to 10 mL of ethanol solution of cobalt nitrate with a concentration of 0.2 mol / L. Ethyl ester in ethanol, at 25 o After reacting at C for 48 h, the obtained precipitate was centrifuged and washed with deionized water, and dried to obtain the precursor powder;

[0032] (2) Mix the precursor powder and magnesium powder uniformly at a mass ratio of 1:1, place in an argon atmosphere, and heat to 700 oC to make it react and keep it warm for 5 h. After cooling, the product was washed with 2 mol / L hydrochloric acid, and then washed repeatedly with deionized water. After drying, the mesoporous silicon / cobalt disilicide composite microsphere material was obtained.

[0033] In the obtained mesoporous silicon / cobalt disilicide composite microsphere material, the mass fraction of silicon is 80%, the mass fraction of cobalt di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com