Composite conductive agent, preparation method thereof and application of composite conductive agent in positive electrode slurry

A composite conductive agent and composite conductive technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as affecting conductivity, high internal resistance, and easy electrode polarization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

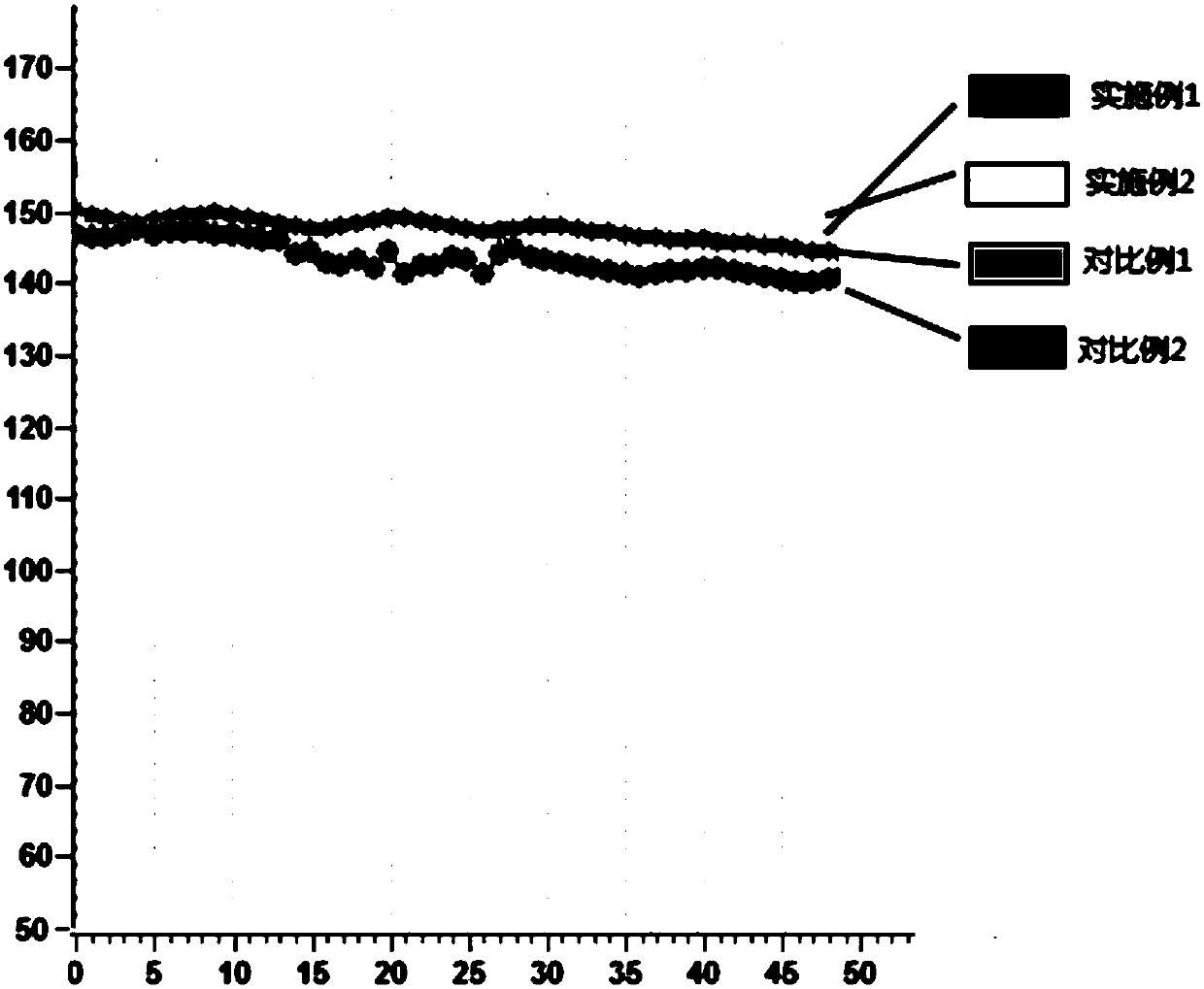

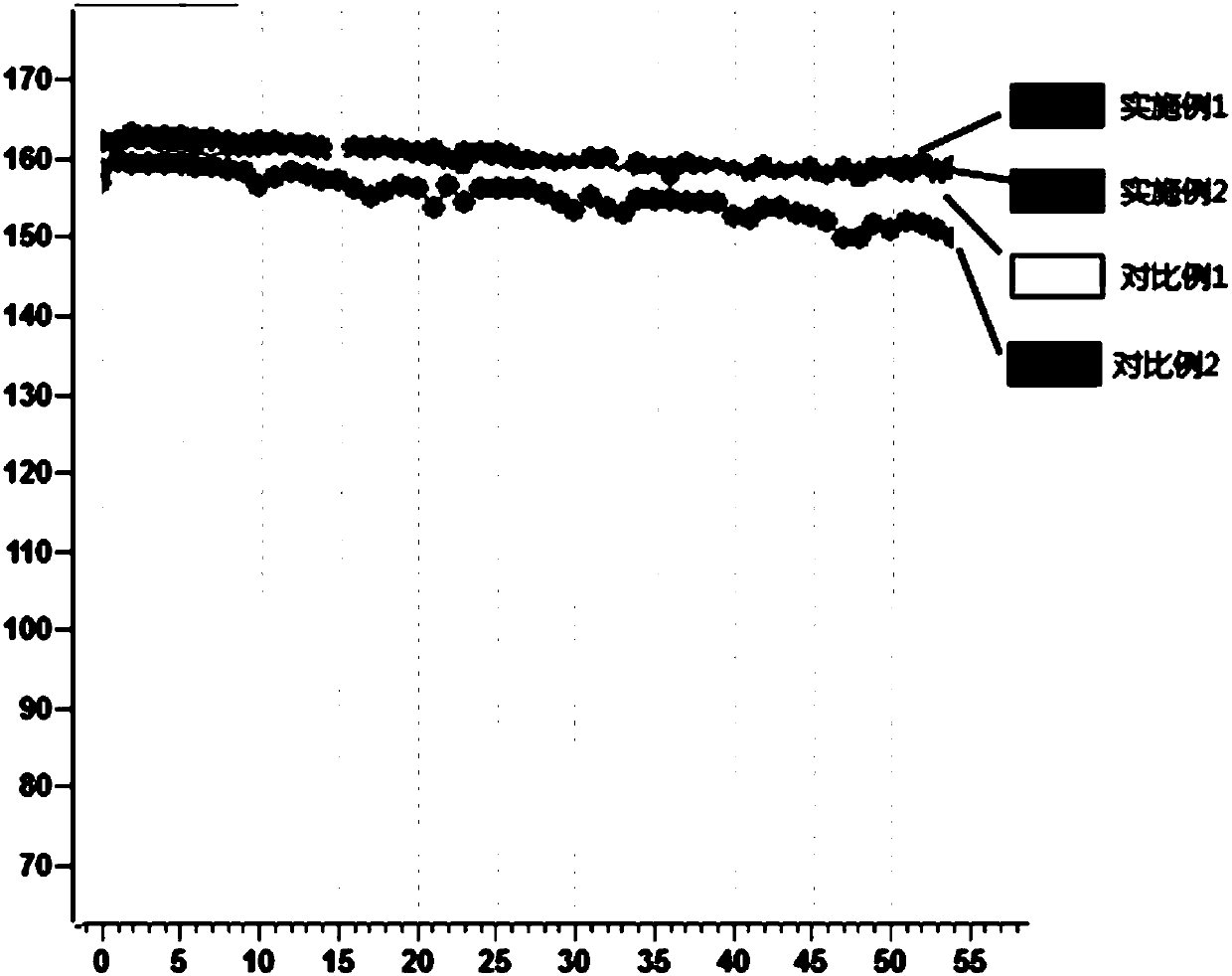

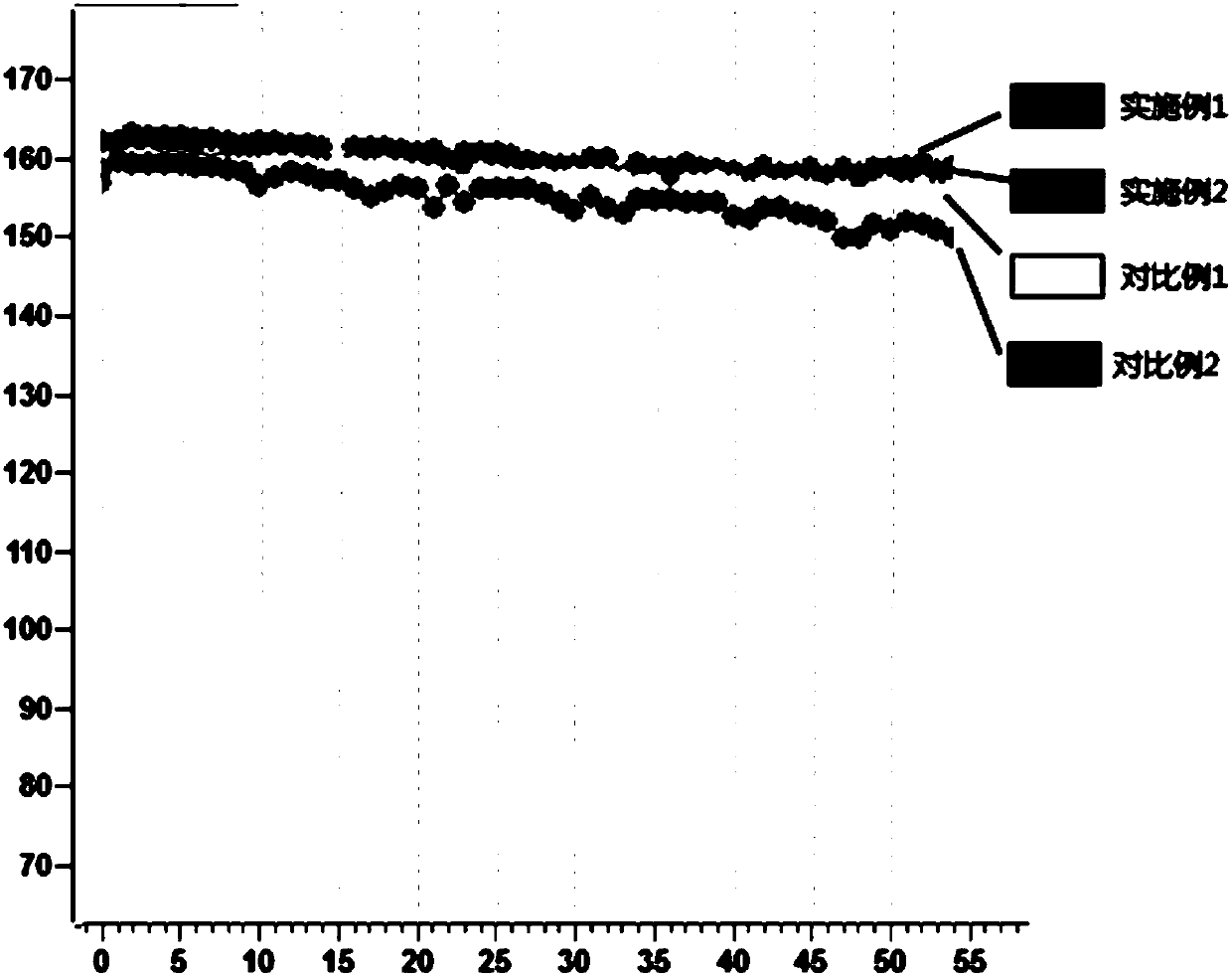

Embodiment 1

[0089] This embodiment provides a composite conductive agent, and the specific process for preparing the composite conductive agent is as follows:

[0090] 1. Preparation of acetylene black and conductive graphite mixed conductive agent (the first composite conductive paste)

[0091] The acetylene black and the conductive graphite were respectively cleaned with acetone, and dried in a vacuum drying oven. Add nano-aluminum powder and stir in the acetylene black after acetone cleaning and drying, obtain the acetylene black modified by nano-aluminum powder (the total mass of the acetylene black modified by nano-aluminum powder is 100%, the amount of the nano-aluminum powder mass percent is 5%).

[0092] Add the mixed acetylene black (i.e. the acetylene black modified by nano-aluminum powder) and conductive graphite into the NMP at a mass ratio of 1:0.5, wherein the solid content is 10-30%, and use a 700-800rpm high-speed stirrer (dispersion disc ) dispersed for 2-3h, put into t...

Embodiment 2

[0102] This embodiment provides a composite conductive agent, and the specific process for preparing the composite conductive agent is as follows:

[0103] 1. Preparation of acetylene black and conductive graphite mixed conductive agent (the first composite conductive paste)

[0104] The acetylene black and the conductive graphite were respectively cleaned with acetone, and dried in a vacuum drying oven. Add nano-aluminum powder and stir in the acetylene black after acetone cleaning and drying, obtain the acetylene black modified by nano-aluminum powder (the total mass of the acetylene black modified by nano-aluminum powder is 100%, the amount of the nano-aluminum powder mass percent is 5%).

[0105] Add the mixed acetylene black (i.e. the acetylene black modified by nano-aluminum powder) and conductive graphite into the NMP at a mass ratio of 1:1, wherein the solid content is 10-30%, and use a 700-800rpm high-speed mixer (dispersing disc ) dispersed for 2-3h, put into the g...

Embodiment 3

[0114] This embodiment provides a composite conductive agent, and the specific process for preparing the composite conductive agent is as follows:

[0115] 1. Preparation of acetylene black and conductive graphite mixed conductive agent (the first composite conductive paste)

[0116] The acetylene black and the conductive graphite were respectively cleaned with acetone, and dried in a vacuum drying oven. Add nano-aluminum powder and stir in the acetylene black after acetone cleaning and drying, obtain the acetylene black modified by nano-aluminum powder (the total mass of the acetylene black modified by nano-aluminum powder is 100%, the amount of the nano-aluminum powder The mass percentage is 3.5%).

[0117] Add the mixed acetylene black (i.e. acetylene black modified by nano-aluminum powder) and conductive graphite into NMP at a mass ratio of 1:0.5, wherein the solid content is 20%, and disperse for 3 hours with an 800rpm high-speed mixer (dispersing disc), Put it in the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com