Battery cathode diachylon formulation high in utilization rate of active substance and preparation method of battery cathode diachylon formulation

A battery negative electrode and utilization rate technology, applied to battery electrodes, circuits, electrical components, etc., can solve problems affecting the cycle life of negative electrode active materials, reduce the apparent density of negative electrode paste, increase the acid content of lead paste, etc., to improve the initial Capacitance and charge acceptance, reduced current density, and improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Mechanically premix lignin Vanisperse AT 0.25Kg, nano-hollow barium sulfate 0.92Kg, and acetylene black 0.225Kg. After the premixing is uniform, the whole is dispersed in 100Kg of lead powder for dry mixing and mixing. The dry mixing time is controlled at 10 ~ Within 15 minutes;

[0029] Within a certain range, prolonging the stirring time is beneficial to improve the dispersion of Vanisperse AT, nano hollow barium sulfate, and acetylene black in the lead powder, so that the additives can be evenly dispersed in the lead powder, but if the stirring time is too long, it will easily lead to low production efficiency.

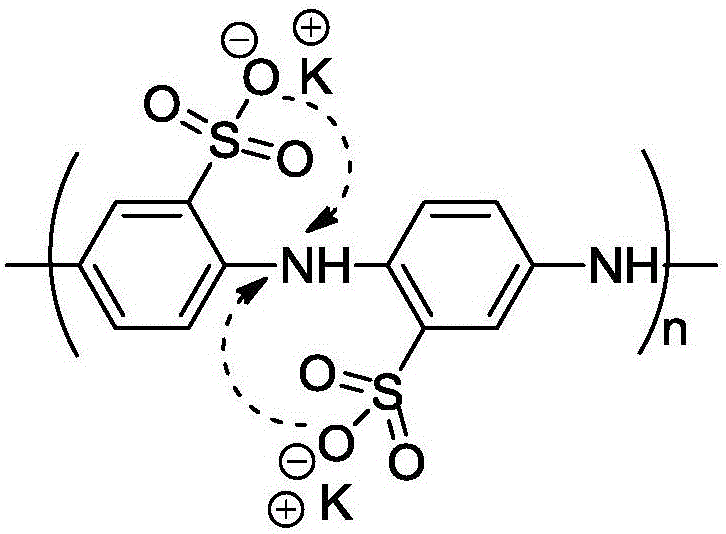

[0030] 2) Mix 0.125Kg of potassium polyaniline sulfonate PAN-K in 7Kg of deionized water in advance to prepare a suspension, then quickly add it and 3Kg of emulsion carbon nanotubes into the above-mentioned mixed lead powder for wet stirring, and the wet stirring time Control within 3 to 5 minutes;

[0031] 3) Slowly add 10.2Kg sulfuric acid aqueous solu...

Embodiment 2

[0034] 1) Mechanically premix lignin Vanisperse AT 0.25Kg, nano-hollow barium sulfate 0.98Kg, and acetylene black 0.21Kg. After the premixing is uniform, the whole is dispersed in 100Kg of lead powder for dry mixing and mixing. The dry mixing time is controlled at 10 ~ Within 15 minutes;

[0035] 2) 0.145Kg of potassium polyaniline sulfonate PAN-K was fully stirred in 6.82Kg of deionized water in advance to prepare a suspension, and then quickly added to the above-mentioned mixed lead powder together with 3.2Kg of emulsion carbon nanotubes for wet stirring. Stirring time is controlled within 3 to 5 minutes;

[0036] 3) Slowly add 9.9Kg sulfuric acid aqueous solution with a density of 1.38g / mL to the uniformly wet-stirred lead paste, and continue to stir within 18-20 minutes. During the entire negative electrode paste mixing process, the paste temperature must be strictly controlled at Between 45°C and 55°C, use 0.35Kg deionized water to fine-tune the apparent density of the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| oxidation state | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com