Method for preparing lithium titanate by spray drying-solid phase method

A technology for preparing lithium titanate and solid-phase method, which is applied in the direction of titanate, alkali metal titanate, chemical instruments and methods, etc., can solve the problems of violent reaction process, volume expansion, safety accidents, etc., and achieve chemical uniformity Good, slow down the electrode polarization, improve the effect of discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

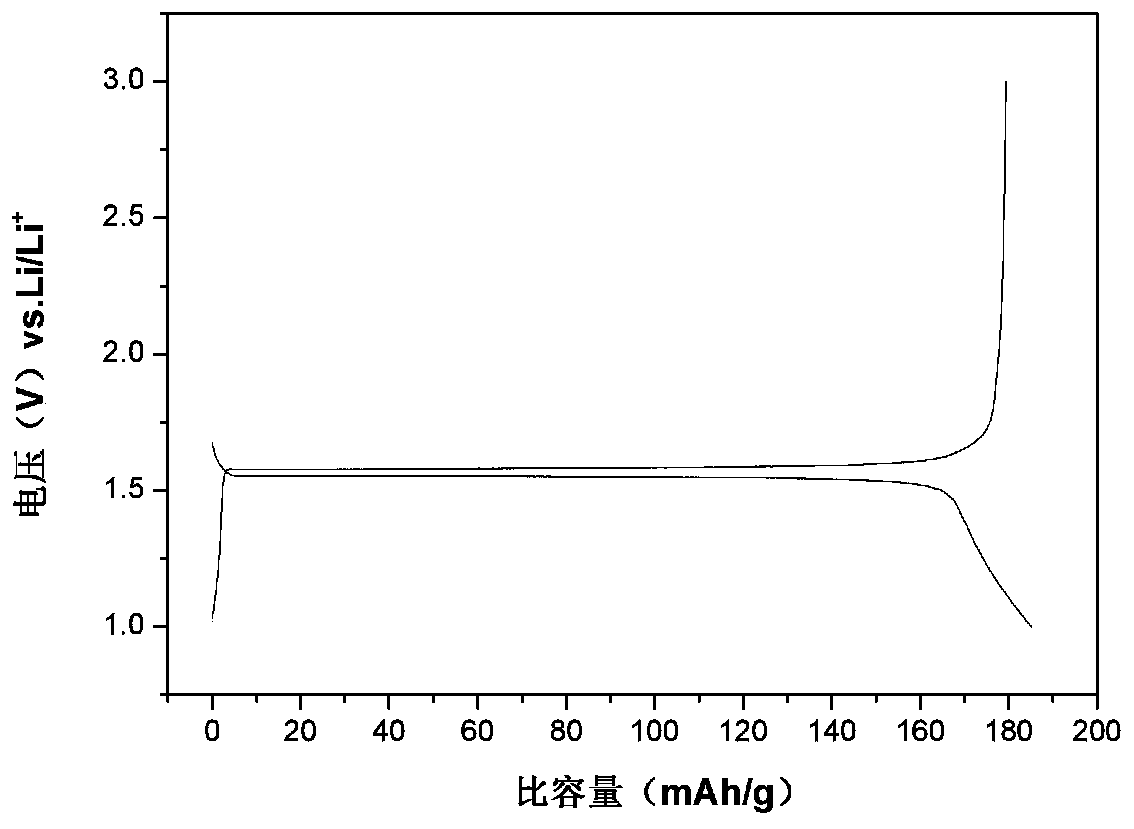

[0035] Preparation of lithium titanate material: Weigh tetrabutyl titanate according to the Li:Ti molar ratio of 0.816:1, add ammonia water, the pH of the ammonia water is 10, hydrolyze into titanyl hydroxide in an ice bath, add concentrated nitric acid A clear solution of titanyl nitrate was prepared by sonication. Weigh lithium nitrate according to the ratio of Li:Ti molar ratio of 0.816:1, add glycerol equivalent to 1.0wt% tetrabutyl titanate quality to form the first solution, add titanyl nitrate to the first solution , and stir evenly; then carry out spray drying, the spray drying system is set, the inlet temperature is set to 190°C, the feed rate is 650mL / h, and the atomizer pressure is 2Mpa to obtain the lithium titanate precursor powder. Spherical lithium titanate sample 1 was obtained by roasting at 800°C for 6 hours in an air atmosphere and cooling to room temperature.

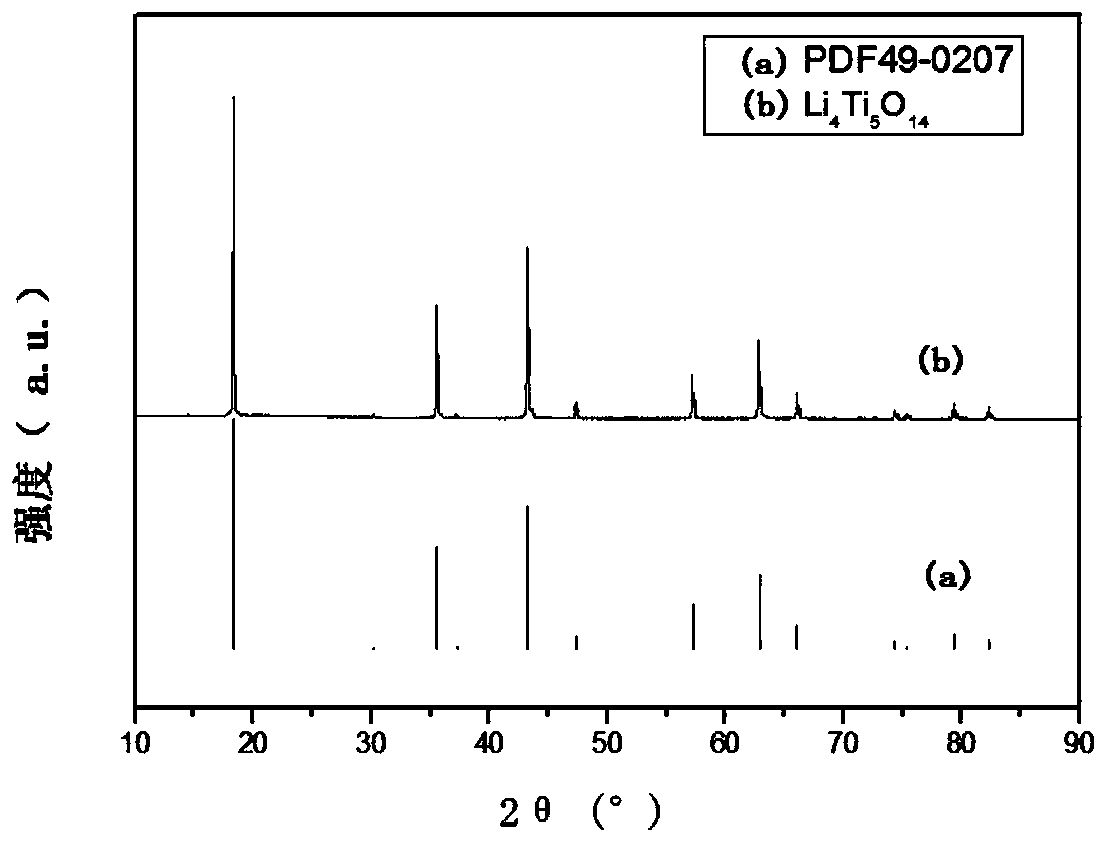

[0036] pass figure 2 It can be seen from the XRD pattern that the present invention successful...

Embodiment 2

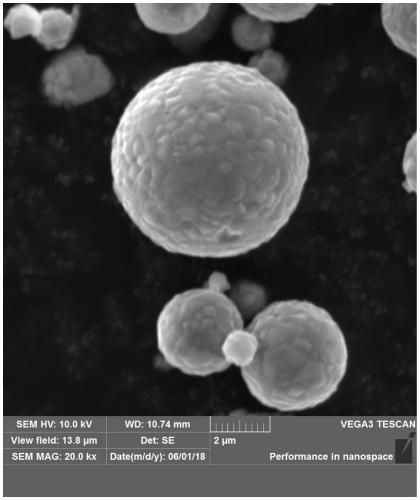

[0039] The preparation process of the lithium titanate material is the same as in Example 1, but the Li:Ti molar ratio is changed to 0.856:1, and the spherical lithium titanate sample 2 is obtained. pass figure 1 It can be seen from the scanning electron microscope photos that the lithium titanate material prepared by the present invention is micro-nano spherical lithium titanate particles, and the lithium titanate particles have a high degree of diffusion, good chemical uniformity, and uniform distribution at the atomic level. The lithium titanate negative electrode material for lithium ion battery prepared in this example was used as the working electrode, and the charge and discharge test was the same as in Example 1. The results showed that the discharge capacity could reach 159.3mAh / g at a current density of 0.1C, and the coulombic efficiency was 96.2%. , The capacity retention rate after 20 laps is 96.6%.

Embodiment 3

[0041] The preparation process of the lithium titanate material is the same as in Example 1, but the Li:Ti molar ratio is changed to 0.9:1, and the spherical lithium titanate sample 3 is obtained. The lithium-ion battery lithium titanate negative electrode material prepared in this example is used as the working electrode, and the charge and discharge test is the same as in Example 1. The results show that the discharge capacity can reach 166.9mAh / g at a current density of 0.1C, and the Coulombic efficiency is 93.8%. , The capacity retention rate after 20 laps is 95.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com