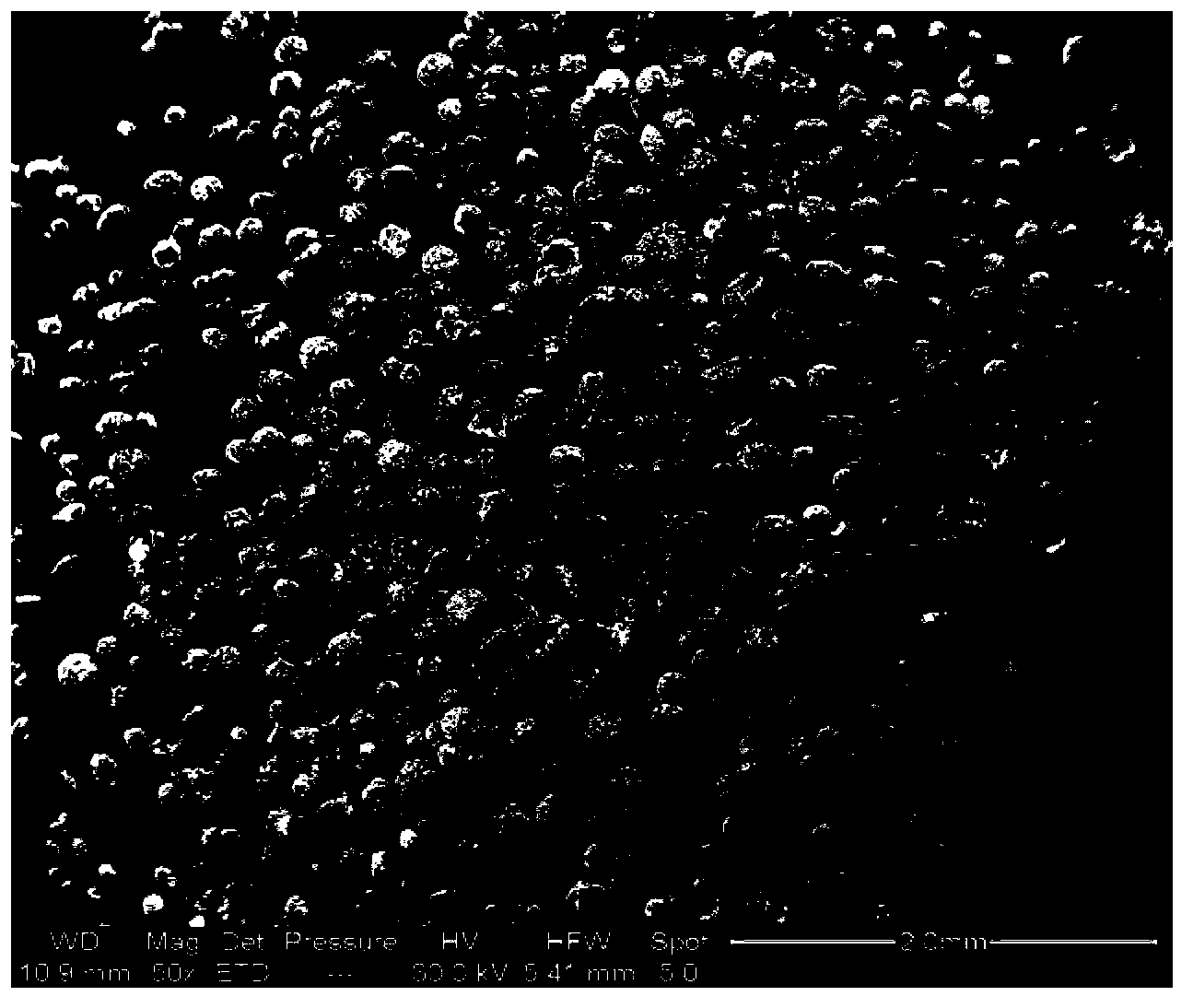

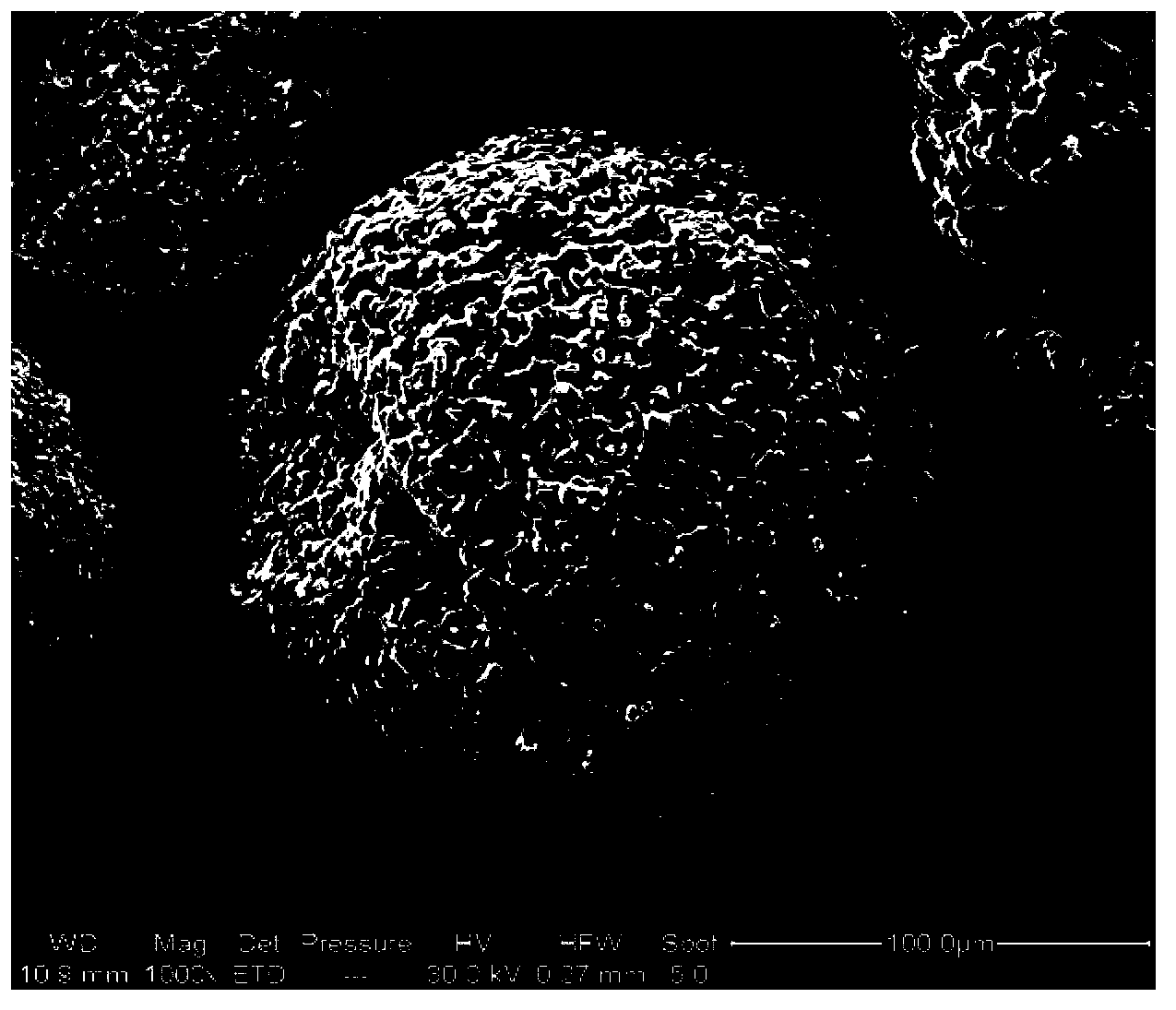

High-activity hollow-out silver powder and preparation method thereof

A high-activity silver powder technology, applied in the field of high-activity silver powder preparation, can solve problems such as large concentration gradient, lower positive electrode potential, and large concentration polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Prepare silver nitrate into a solution with a concentration of 65 g / L, macroporous resin (styrene-divinylbenzene resin, average particle size 0.35 mm, average pore size of the resin The specific surface area is 650 square meters / g) In the plexiglass column, the silver nitrate solution prepared above is fed at a flow rate of 75 ml / min by the method of extraction chromatography, and the received solution is checked with a 10% sodium chloride solution. White precipitation starts, and the received solution recycle and re-use. The silver nitrate resin thus obtained was transferred to the barrel for reduction experiment.

[0024] (2) Put the barrel containing the silver nitrate resin obtained in step (1) into a 65°C hot water bath, stir the silver nitrate resin, and heat it until the temperature of the silver nitrate resin is 30°C, and add 70 ml of ammonia while stirring. When the silver nitrate resin system reaches pH=8, add 180 ml of hydrazine hydrate, continue to stir f...

Embodiment 2

[0027] (1) Prepare silver nitrate into a solution with a concentration of 220 g / L, and mix the macroporous resin (styrene-methyl methacrylate with a specific surface area of 750m 2 / g, average pore size , Average particle size 0.64 mm) into In the organic glass column, the extraction chromatography method is adopted, and the flow rate of the silver nitrate solution is 300 ml / min to obtain the silver nitrate resin.

[0028] (2) When the silver nitrate resin obtained in step (1) is heated to 60°C, add ammonia under stirring. When the silver nitrate resin system reaches pH=8, add 180 ml of hydrazine hydrate, continue stirring for 30 minutes, and leave for 1 hour Above, the reduction of silver is complete, and silver resin is obtained. Wash with deionization to obtain a silver resin with a pH of 7, and then filter, and put the filtered silver resin into a dish. In an oven, dry for 12 hours at a temperature of 100°C.

[0029] (3) Put the dried silver resin into the crucible, then p...

Embodiment 3

[0031] (1) Prepare silver nitrate into a solution with a concentration of 120 g / L, and mix the macroporous resin (styrene-ethanol dimethacrylate, specific surface area 950m 2 / g, aperture (Average particle size 0.75 mm) loaded In the organic glass column, the extraction chromatography method is adopted, and the flow rate of the silver nitrate solution is 200 ml / min to obtain the silver nitrate resin.

[0032] (2) When the silver nitrate resin obtained in step (1) is heated to 70℃, add ammonia while stirring. When the silver nitrate resin system reaches pH=8, add 180 ml of hydrazine hydrate, continue stirring for 30 minutes, and leave it for more than 1 hour , The silver reduction is complete, and silver resin is obtained. Wash with deionization to obtain a silver resin with a pH of 7, and then filter, and put the filtered silver resin into a dish. In an oven, dry for 3 hours at a temperature of 180°C.

[0033] (3) Put the dried silver resin into the crucible, then put it into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com