Method of preparing heat-proof xylanase, heat-proof beta-xylosidase or heat-proof beta-glucosidase

A technology of glucosidase and xylanase, applied in the direction of hydrolase, bacteria, etc., to achieve the effect of reducing production cost, improving tissue structure and reducing initial hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

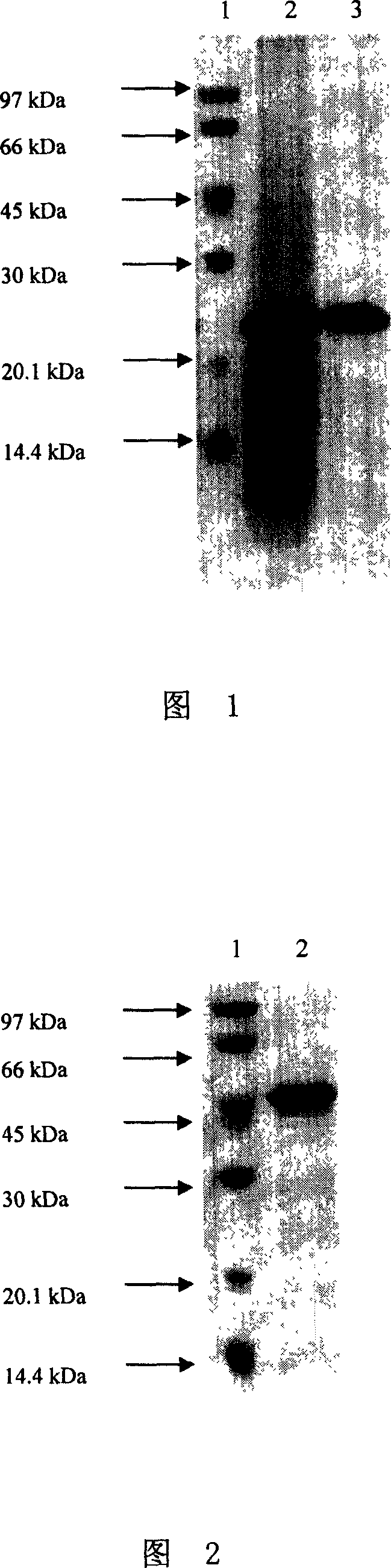

[0045] Embodiment 1, the preparation of thermostable xylanase

[0046] 1. Production of thermostable xylanase by solid fermentation

[0047] 1) Cultivation of Paecilomyes thermophila J18 for inoculation:

[0048] Paecilomyes thermophila (Paecilomyes thermophila) J18 (purchased from the Culture Collection Center of the Institute of Microbiology, Chinese Academy of Sciences, with a preservation number of AS3.6885) seeds were streaked and inoculated from the preserved PDA slant on a newly prepared PDA slant or plate, and then Place the slant or plate in a 40-60°C incubator for static culture for 2-8 days. The spores on the inclined surface are washed with 20% glycerol solution by mass percentage, the washed spore liquid is used for solid fermentation to produce enzyme, and the grown plate is directly used for liquid fermentation.

[0049] 2) Production of xylanase liquid by solid fermentation

[0050] Paecilomyces thermophila J18 was used as fermentation strain and natural agr...

Embodiment 2

[0073] Embodiment 2, the preparation of thermostable β-xylosidase

[0074] 1. Production of thermostable β-xylosidase by solid fermentation

[0075] 1) Cultivation of Paecilomyes thermophila J18 for inoculation:

[0076] The seeds of Paecilomyces thermophila J18 (purchased from the Culture Collection Center of the Institute of Microbiology, Chinese Academy of Sciences, with the preservation number AS3.6885) were streaked and inoculated from the preserved slant on the newly prepared PDA slant or plate, and then the slant or plate was placed Cultivate statically in a 40-60°C incubator for 2-8 days. The spores on the inclined surface are washed with 20% glycerol solution by mass percentage, the washed spore liquid is used for solid fermentation to produce enzyme, and the grown plate is directly used for liquid fermentation.

[0077] 2) Production of thermostable β-xylosidase by solid fermentation

[0078] Using Paecilomyces thermophilia J18 (purchased from the Culture Collecti...

Embodiment 3

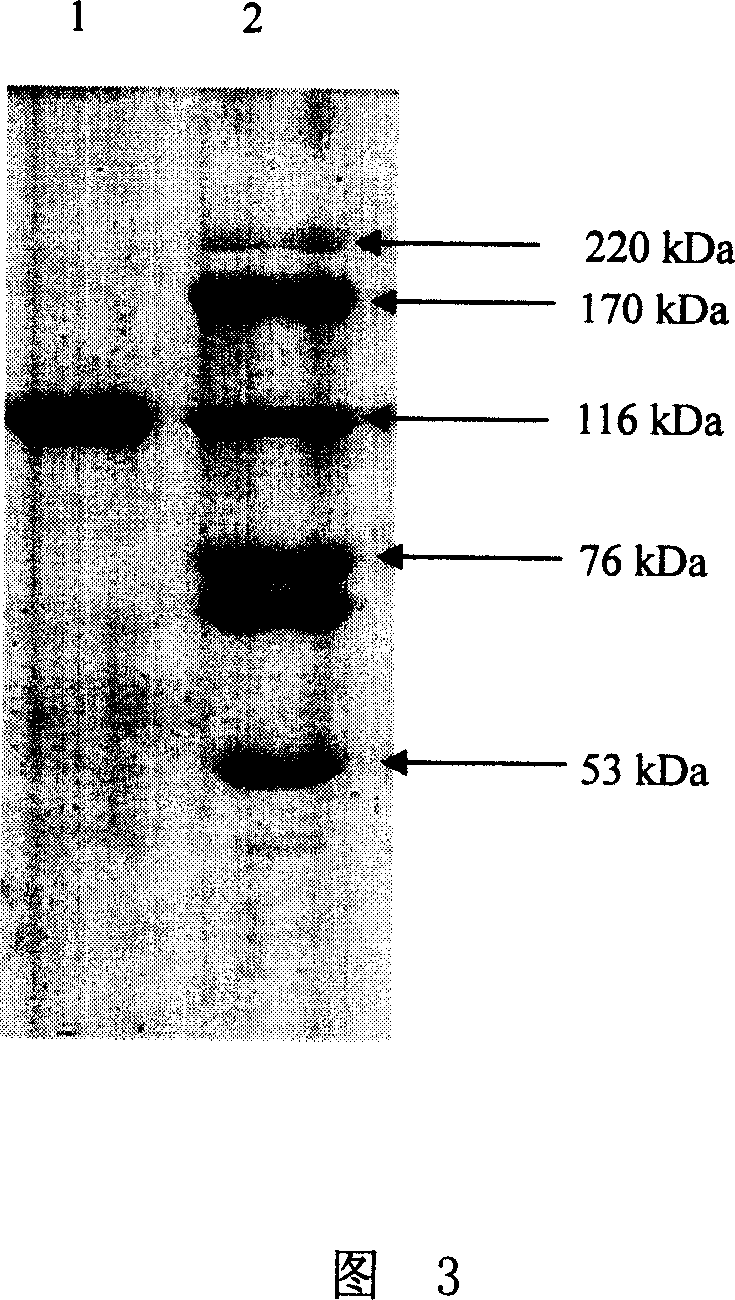

[0111] Embodiment 3, the preparation of heat-resistant β-glucosidase liquid

[0112] 1. Production of thermostable β-glucosidase by solid fermentation

[0113] 1) Cultivation of Paecilomyes thermophila J18 for inoculation:

[0114] Paecilomyces thermophila J18 seeds were streaked and inoculated on a newly prepared PDA slant or plate from the preserved slant, and then the slant or plate was placed in a 40-60°C incubator for static culture for 2-8 days. The spores on the inclined surface are washed with 20% glycerol solution by mass percentage, the washed spore liquid is used for solid fermentation to produce enzyme, and the grown plate is directly used for liquid fermentation.

[0115] 2) Production of thermostable β-glucosidase by solid fermentation

[0116] The thermostable glucosidase was produced by solid fermentation with Paecilomyces thermophila J18 as the fermentation strain and natural agricultural waste wheat straw as the carbon source.

[0117] The medium of solid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com