Super capacitor taking polyaniline/aligned carbon nanotube compound film as electrode and manufacturing method thereof

A technology of oriented carbon nanotubes and supercapacitors, applied in electrolytic capacitors, hybrid capacitor electrodes, capacitors, etc., can solve the problems of rare supercapacitors, flexible transparent supercapacitors with high electrical performance, etc., to improve cycle stability and good flexibility. and transparency, the effect of stable cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

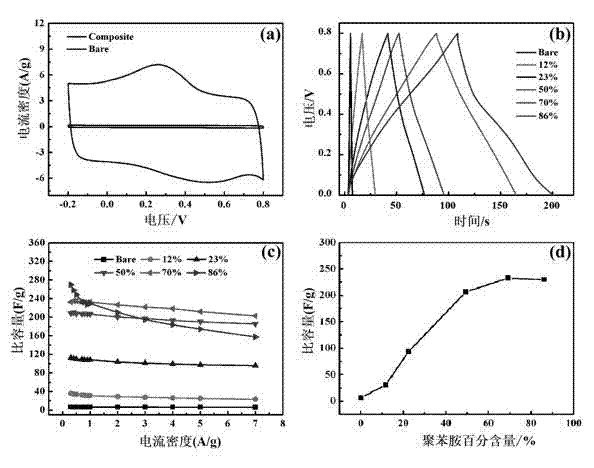

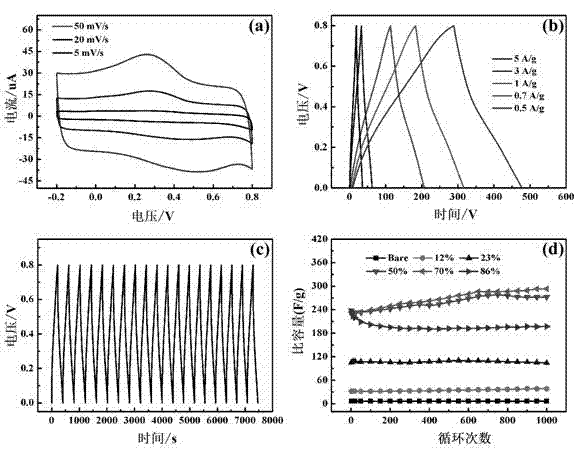

Examples

Embodiment 1

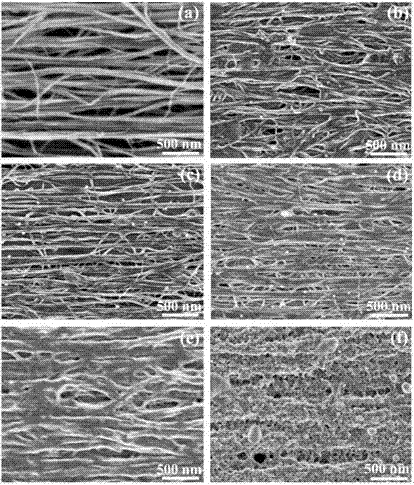

[0029] 1. Synthesis of aligned carbon nanotube arrays[19, 20]

[0030] Aligned carbon nanotube arrays with Fe(1.2nm) / Al 2 o 3 (3nm) / SiO2 2 / Si as a catalyst was synthesized using a typical chemical vapor deposition method in a quartz tube of a tube furnace. Al in the catalyst 2 o 3 Located in the middle of the silicon wafer and Fe, as a buffer layer, Fe as a catalyst, Al 2 o 3 and Fe are prepared by depositing a nanometer-thick film on a silicon wafer by an electron beam evaporation coater;

[0031] Using chemical vapor deposition method, using ethylene as carbon source, argon and hydrogen as carrier gas (gas flow: ethylene 90sccm, hydrogen 30sccm, argon 400sccm), synthesized spinnable aligned carbon nanotube arrays on Si substrate with oxide layer , the diameter of the obtained aligned carbon nanotubes is 12nm.

[0032] 2. Preparation of Polyaniline / Aligned Carbon Nanotube Films

[0033] a) Aligned carbon nanotube films were prepared by a dry spinning process. Using...

Embodiment 2

[0039] 1. Synthesis of aligned carbon nanotube arrays[19, 20]

[0040] Synthetic method is with embodiment 1, and wherein Fe particle diameter is 1.0nm, Al 2 o 3 The particle diameter is 2nm, the gas flow rate is: ethylene 85sccm, hydrogen 25sccm, argon 400sccm, and the diameter of the obtained aligned carbon nanotube array is 8nm.

[0041] 2. Preparation of Polyaniline / Aligned Carbon Nanotube Films

[0042] a) The aligned carbon nanotube film is prepared by a dry spinning process, the preparation method is the same as in Example 1, and the mass surface density of the obtained carbon nanotube film is: 1.30 μg / cm 2 ;

[0043] b) After the drawn carbon nanotube film, first coat one side with silver glue, and then coat the other side with two-component modified epoxy resin adhesive 504 glue and dry at 60-80°C;

[0044] c) preparation of electrolyte: method is the same as embodiment 1, and in the solution obtained, sulfuric acid concentration is 1.6M, and aniline concentration...

Embodiment 3

[0048] 1. Synthesis of aligned carbon nanotube arrays[19, 20]

[0049] Synthetic method is the same as embodiment 1, and wherein Fe particle diameter is 1.3nm, Al 2 o 3 The particle diameter is 3nm, the gas flow rate is: ethylene 95sccm, hydrogen 35sccm, argon 410sccm, and the diameter of the obtained aligned carbon nanotube array is 10nm.

[0050] 2. Preparation of Polyaniline / Aligned Carbon Nanotube Films

[0051] a) The aligned carbon nanotube film is prepared by a dry spinning process, the preparation method is the same as in Example 1, and the mass surface density of the obtained carbon nanotube film is: 1.50 μg / cm 2 ;

[0052] b) The drawn carbon nanotube film is first coated with silver glue on one side, and then coated with two-component modified epoxy resin adhesive 504 glue on the other side, and dried at 60-80°C for about 2 hours;

[0053] c) preparation of electrolyte: method is the same as embodiment 1, and in the solution obtained, sulfuric acid concentration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com