Core-shell structured lithium nickel manganese cobalt precursor, fabrication method thereof and application thereof in lithium ion battery

A technology of nickel-cobalt lithium manganese oxide and core-shell structure, applied in battery electrodes, secondary batteries, structural parts, etc. Complicated coating process and other issues, to achieve excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

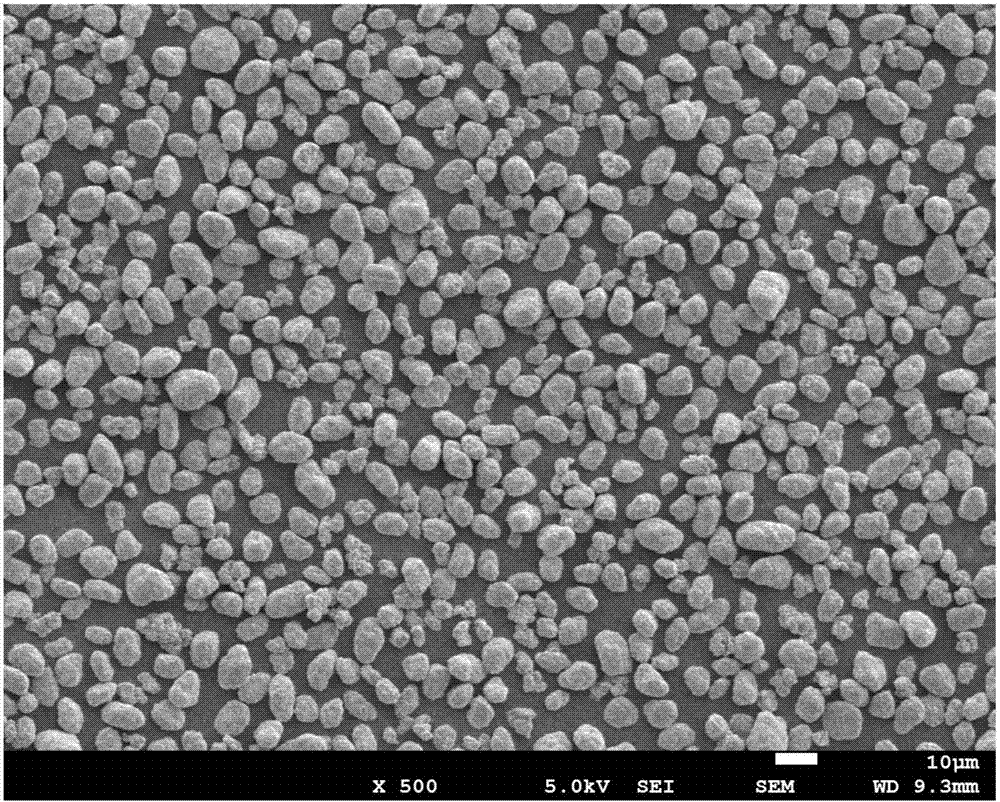

[0102] 1. Preparation of nickel-cobalt-manganese carbonate precursor with core-shell structure

[0103] (1) Weigh the sulfate salt of nickel, cobalt, manganese, be mixed with the mixed salt solution A that concentration is 2.5mol / L according to Ni, Co, M molar ratio is 8:1:1, mix solution A, precipitant Na 2 CO 3 solution, complexing agent sodium acetate solution, under continuous stirring, flow into the reactor, so that Ac - :(Ni+Mn+Co)=1:1, Na 2 CO 3 The concentration of the solution is 2.5mol / L, adding the pH regulator NH 4 HCO 3 Solution, the pH value of the solution was adjusted to 8.5, and the inner core precursor slurry M1 was obtained by a controlled crystallization precipitation method.

[0104] (2) Weigh the sulfate salt of nickel, cobalt and manganese, according to Ni, Co, M molar ratio is 6:2:2, be mixed with the mixed salt solution B that concentration is 3.0mol / L, solution B, precipitant Na 2 CO 3 Solution, complexing agent sodium acetate solution, under c...

Embodiment 2

[0117] Except the following content, other methods and conditions are identical with embodiment 1:

[0118] When preparing the core-shell structure nickel-cobalt-manganese carbonate precursor, in the step (1), according to Ni, Co, M molar ratio is 7:1:1 to be mixed with the mixed salt solution A that concentration is 2.5mol / L; Step (2 ) in according to Ni, Co, M molar ratio is 5:3:2, is mixed with the mixed salt solution B that concentration is 3.0mol / L;

[0119] When preparing the nitrogen-doped M element oxide, M=Ce, and the particle size of the cerium oxide is 20nm, and the doping amount of nitrogen in the cerium oxide is 1wt%.

[0120] When preparing the surface-coated nickel-cobalt lithium manganese oxide positive electrode material, in the first coating, the ratio of the total amount of zirconia and titanium oxide to the total amount of nickel, cobalt, and manganese is 0.001:1; The drying temperature is 105°C; the calcination temperature is 950°C, and the calcination ti...

Embodiment 3

[0124] Except the following content, other methods and conditions are identical with embodiment 1:

[0125] When preparing the core-shell structure nickel-cobalt-manganese carbonate precursor, in the step (1), according to Ni, Co, M molar ratio is 7.5:1:1 to be mixed with the mixed salt solution A that concentration is 2.5mol / L; Step (2 ) in according to Ni, Co, M molar ratio is 4:3:3, is mixed with the mixed salt solution B that concentration is 3.0mol / L;

[0126] When preparing the nitrogen-doped M element oxide, M=Mg, and the particle size of the magnesium oxide is 85nm, and the doping amount of nitrogen in the magnesium oxide is 0.5wt%.

[0127] When preparing the surface-coated nickel-cobalt lithium manganese oxide positive electrode material, in the first coating, the ratio of the total amount of zirconia and titanium oxide to the total amount of nickel, cobalt, and manganese is 0.1:1; microwave The drying temperature is 80°C; the calcination temperature is 550°C, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com