Preparation method of nano-manganese dioxide electrode

A nano-manganese dioxide and electrode technology, which is applied in the manufacture of hybrid/electric double layer capacitors, circuits, capacitors, etc., can solve the problems of complex powder preparation process and low specific surface area impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

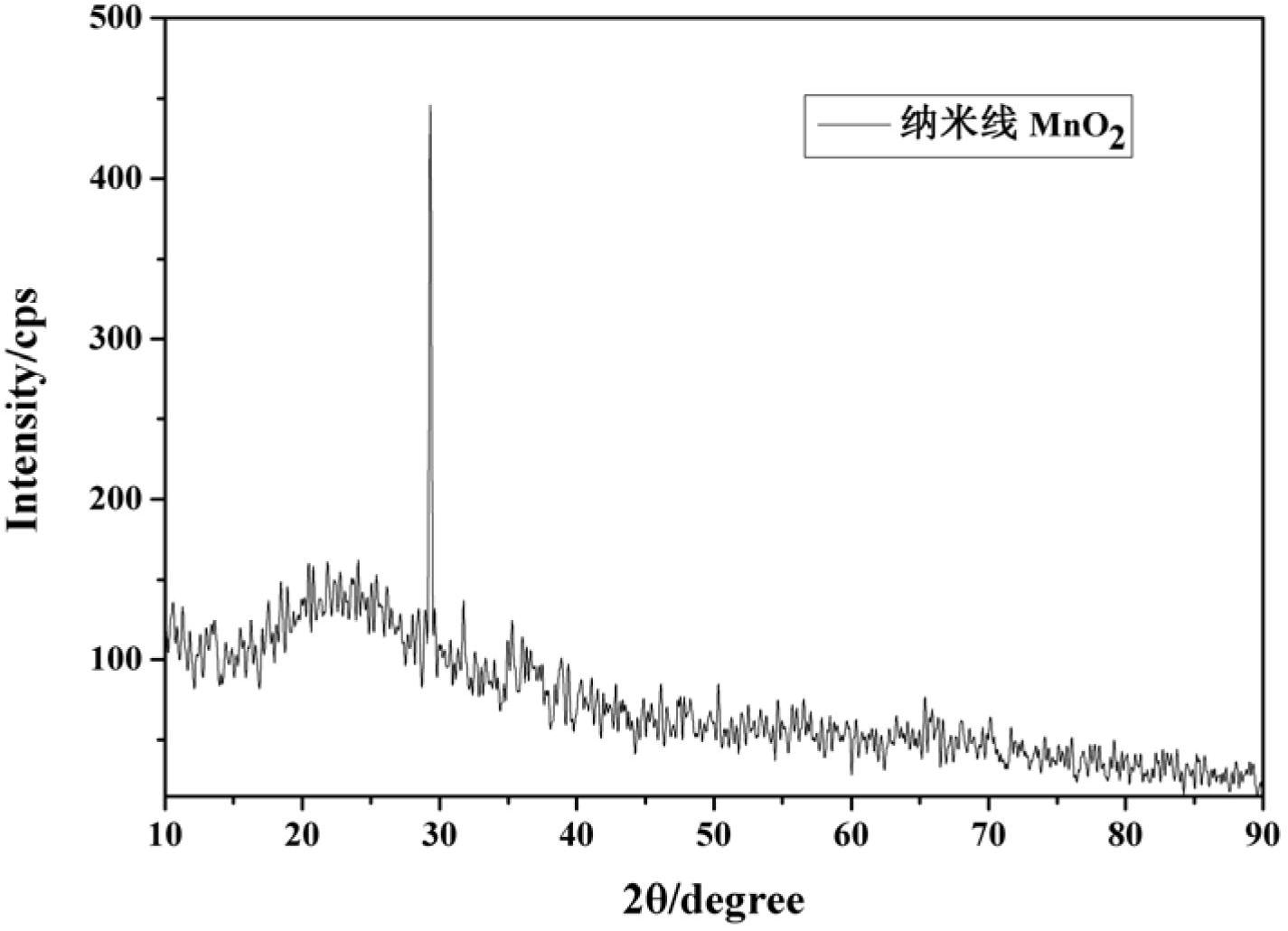

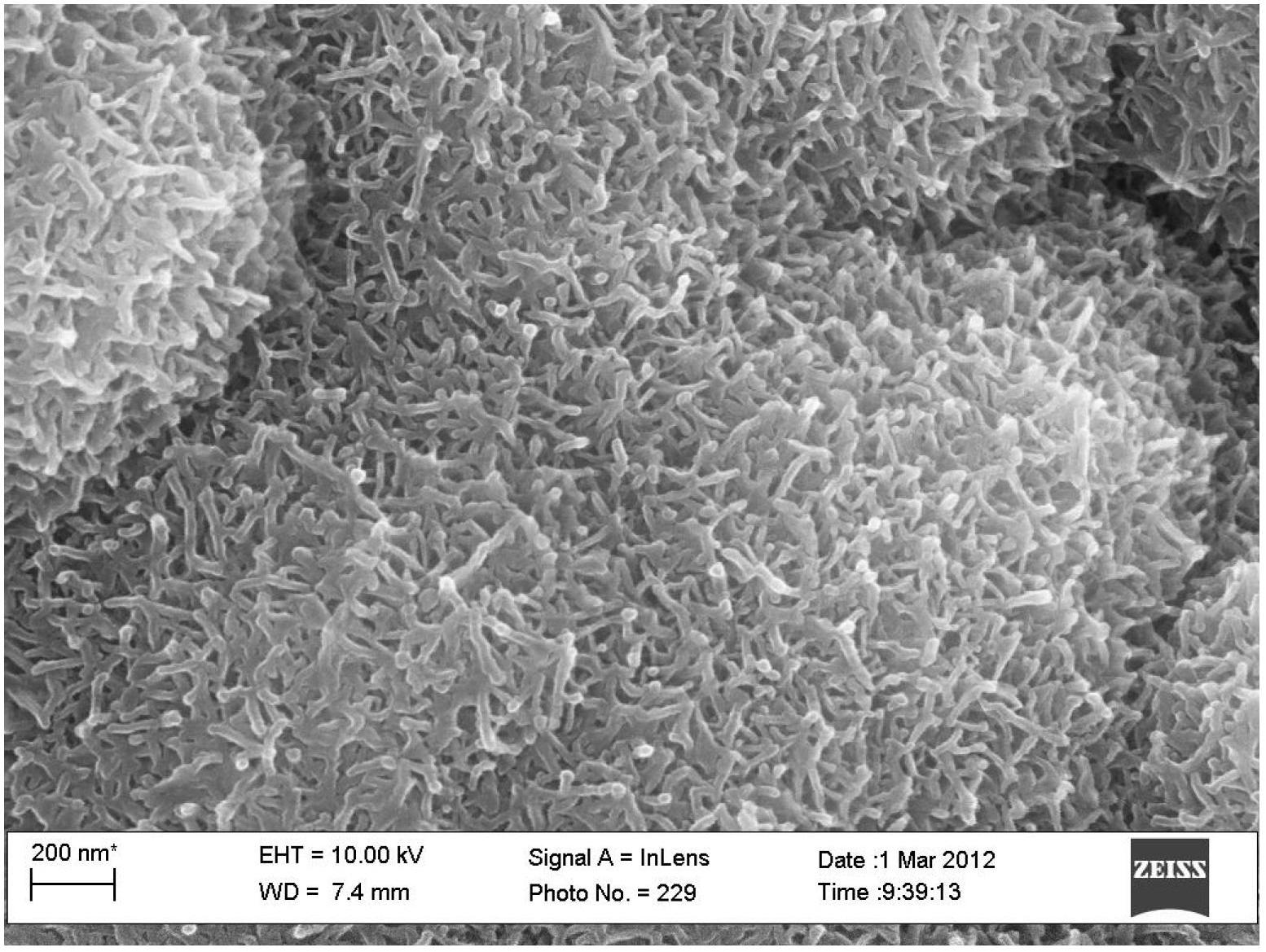

Image

Examples

example 1

[0028] (1) With nickel foam as the substrate, ultrasonic cleaning with acetone solution, deionized water, dilute hydrochloric acid solution (concentration 5%), and deionized water for 10 minutes before constant current pulse deposition, and then placed in a vacuum oven at 100 °C after cleaning Dry in medium.

[0029] (2) 14.7g C 4 h 6 MnO 4 .H 2 O and 5.1g NaNO 3 Prepare 200ml of manganese acetate aqueous solution containing 0.3M sodium nitrate, and add ammonia water drop by drop at room temperature to adjust the pH value to 6.5.

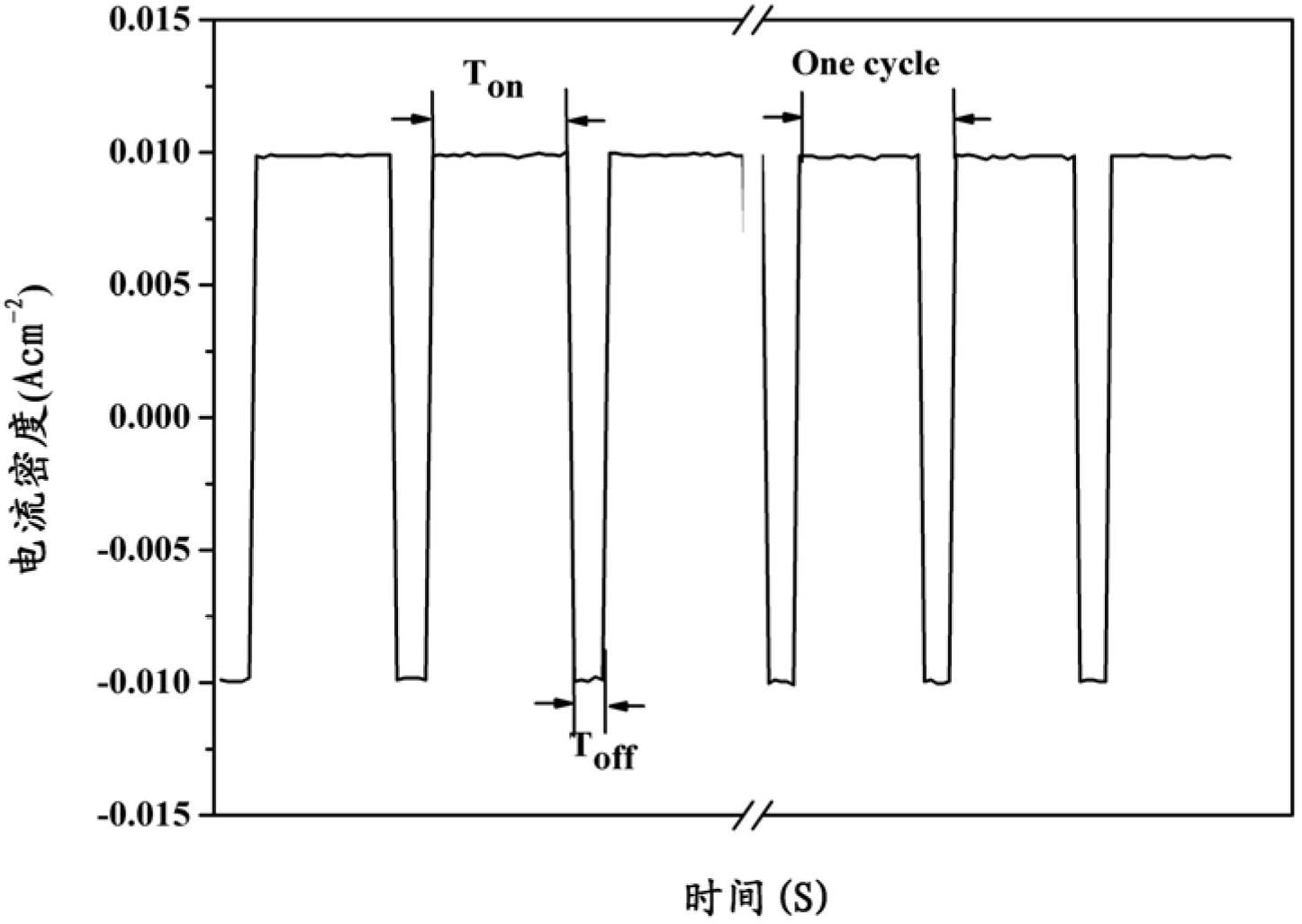

[0030] (3) Nickel foam is the working electrode, graphite plate is the counter electrode, the solution prepared in step (2) is the electrodeposition solution, and a two-electrode system is used for constant current pulse electrodeposition. The deposition parameters are: the anode applied current is 10mA cm -2 , corresponding to the power-on time (T on ) 20S; the cathode current is -10mA·cm -2 , corresponding to the power-on time (T off ) 5S...

example 2

[0034] (1) With nickel foam as the substrate, ultrasonic cleaning with acetone solution, deionized water, dilute hydrochloric acid solution (concentration 5%), and deionized water for 10 minutes before constant current pulse deposition, and then placed in a vacuum oven at 100 °C after cleaning Dry in medium.

[0035] (2) 9.8g C 4 h 6 MnO 4 .H 2 O and 5.1g NaNO 3 Prepare 200ml of manganese acetate aqueous solution containing 0.3M sodium nitrate, and add ammonia water drop by drop at room temperature to adjust the pH value to 6.5.

[0036] (3) Nickel foam is the working electrode, graphite plate is the counter electrode, the solution prepared in step (2) is the electrodeposition solution, and a two-electrode system is used for constant current pulse electrodeposition. The deposition parameters are: the anode applied current is 10mA cm -2 , corresponding to the power-on time (T on ) 20S; the cathode current is -10mA·cm -2 , corresponding to the power-on time (T off ) 5S,...

example 3

[0040] (1) With nickel foam as the substrate, ultrasonic cleaning with acetone solution, deionized water, dilute hydrochloric acid solution (concentration 5%), and deionized water for 10 minutes before constant current pulse deposition, and then placed in a vacuum oven at 100 °C after cleaning Dry in medium.

[0041] (2) 9.8g C 4 h 6 MnO 4 .H 2 O and 6.8g NaNO 3 Prepare 200ml of manganese acetate aqueous solution containing 0.4M sodium nitrate, and add ammonia water drop by drop at room temperature to adjust the pH value to 6.5.

[0042] (3) Nickel foam is the working electrode, graphite plate is the counter electrode, the solution prepared in step (2) is the electrodeposition solution, and a two-electrode system is used for constant current pulse electrodeposition. The deposition parameters are: the anode applied current is 10mA cm -2 , corresponding to the power-on time (T on ) 20S; the cathode current is -10mA·cm -2 , corresponding to the power-on time (T off ) 5S,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com