Method for preparing reflection reduction film with surface embedded type porous silicon structure of silicon base solar battery

A technology of solar cells and anti-reflection coatings, applied in chemical instruments and methods, circuits, electrical components, etc., can solve problems such as lack of crystal orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] The process and steps of this embodiment are as follows

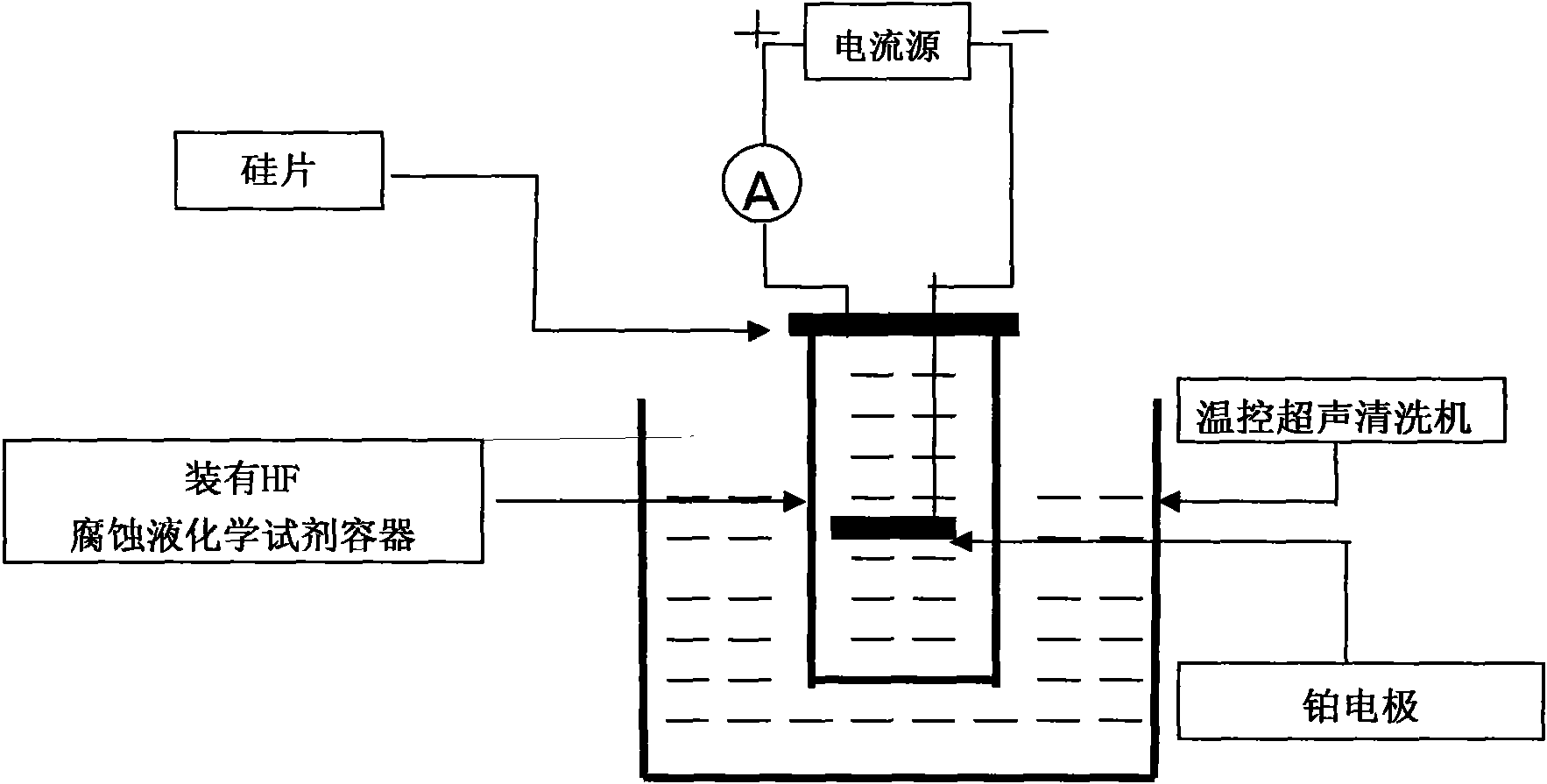

[0024] For the device used in this embodiment, refer to the figure 1 . figure 1 It is a schematic diagram of the device for preparing antireflection film or low reflectivity film by electrochemical corrosion method. The device is a commonly used laboratory device.

[0025] (1) Select solar cell silicon substrate material, which is Czochralski monocrystalline silicon, P type, crystal orientation , thickness is 220 μm, unpolished; first place the silicon wafer as the solar cell silicon substrate material on Preliminary corrosion is carried out in the sodium hydroxide magnetic solution, to remove the mechanical damage layer on the surface of the silicon wafer; the preparation of the lye is that the volume ratio of sodium hydroxide and water is 1:5; the temperature of the lye is 80 ° C; The silicon wafer is placed in the alkali solution and corroded for 1 minute under the action of ultrasonic waves;

[0026] (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com