High-efficiency automatic tungsten needle manufacturing device and method

A preparation device and technology of tungsten needles, which are applied in the field of preparing nano-tungsten needles using automatic control ideas and dynamic corrosion, can solve the problems of difficult to realize the shape of tungsten needles, low corrosion efficiency, low production efficiency, etc., and achieve the corrosion efficiency of tungsten needles The effect of improving, facilitating industrialized production, and increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

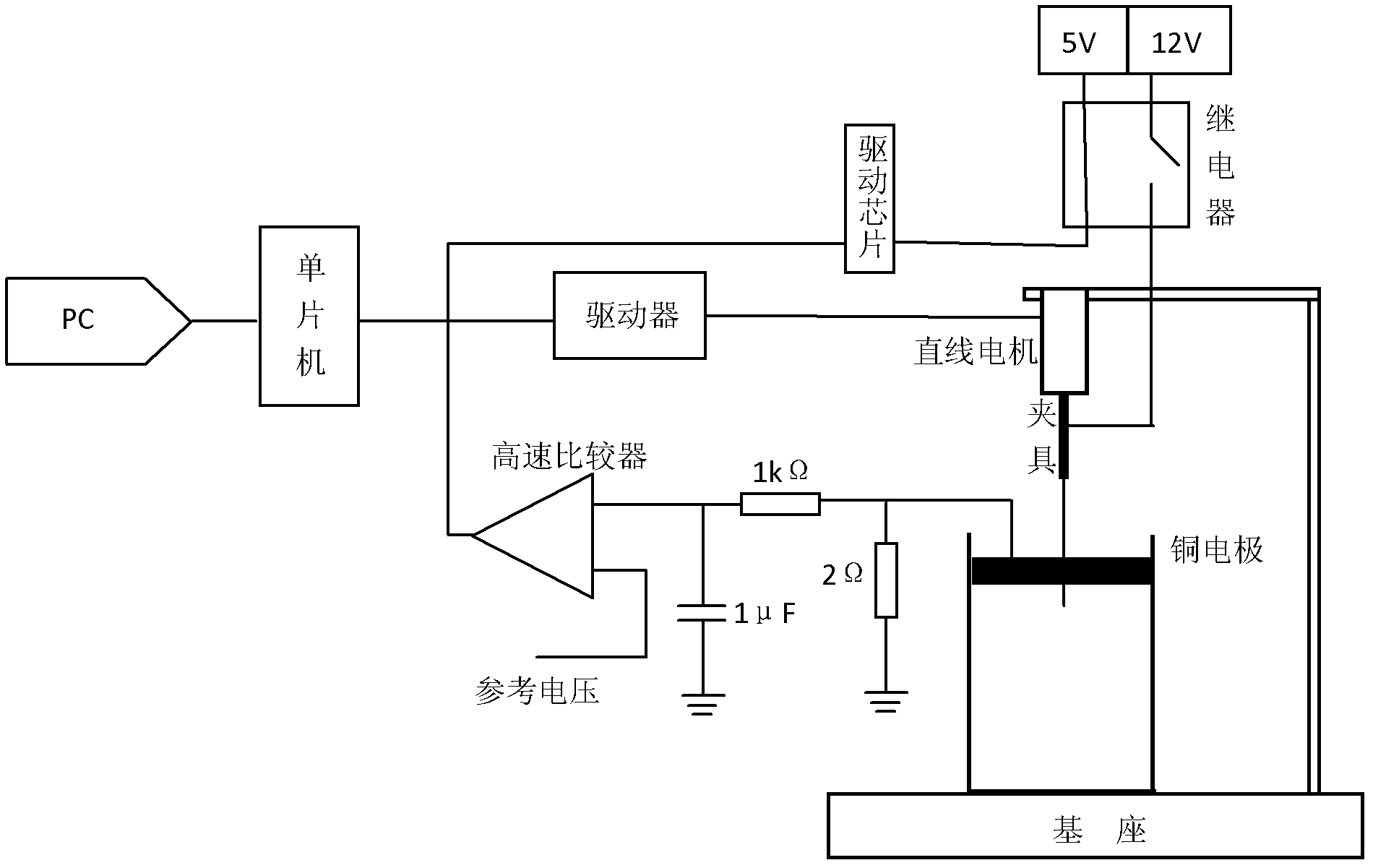

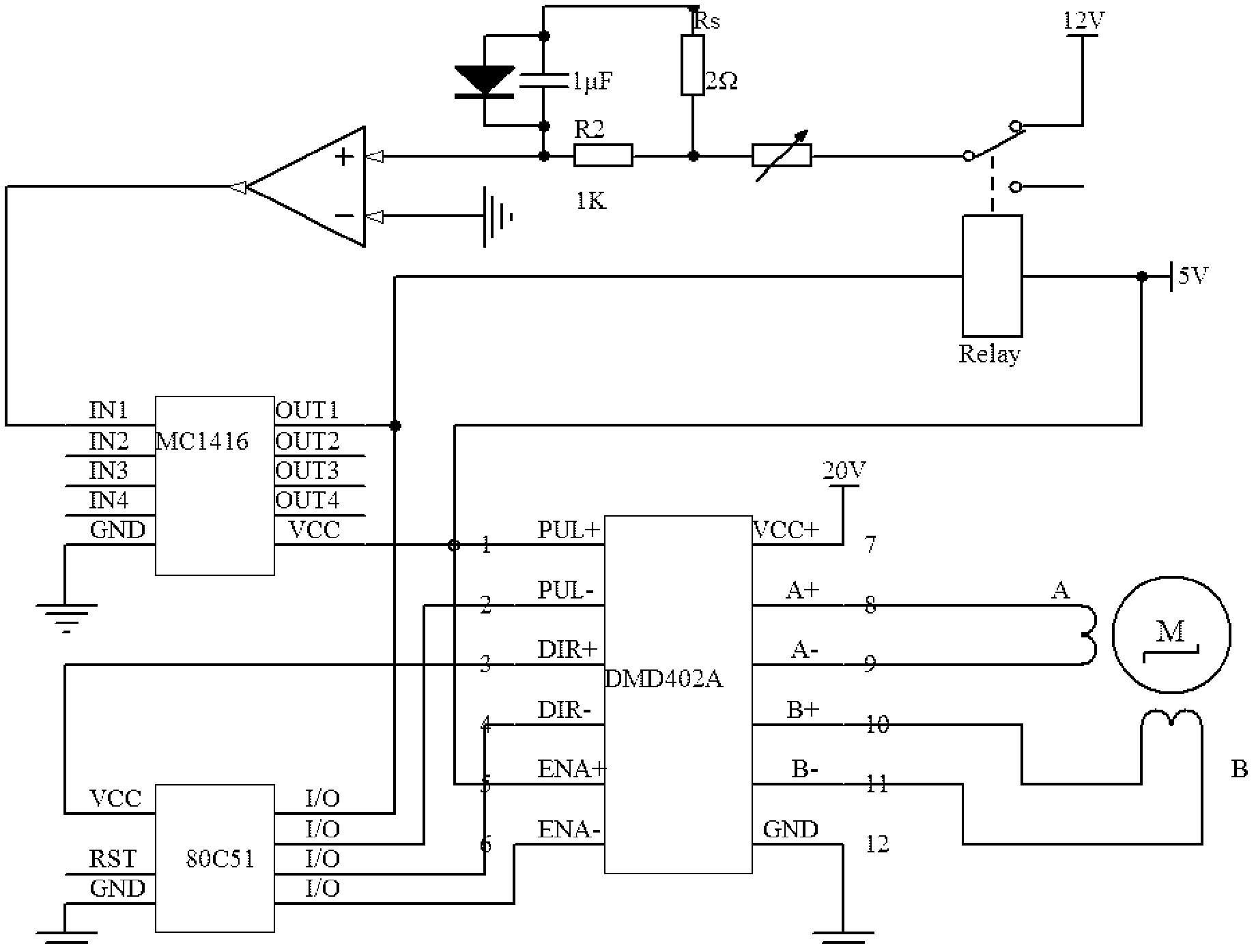

[0020] Such as figure 1 As shown, the tungsten needle dynamic corrosion preparation device of the present invention includes four parts: a fixed base, a positioning system, a control system and an etching solution. The fixed base is a U-shaped fixed frame consisting of a steel frame. Positioning system: It consists of a two-phase hybrid linear stepper motor, a stepper motor driver DM402A, and a tungsten needle fixture. The linear stepper motor is a two-phase mixed type. The guide rail of the linear stepper motor is fixed on the steel frame. The tungsten needle clamping device is fixed on the stepper motor by screws, and the tungsten needle is clamped in the fixture. Control system: It is composed of single-chip microcomputer (80C51), current monitoring feedback circuit, and voltage cut-off circuit. Among them, the single-chip microcomputer controls the motor to mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com