Corrosive for showing white layer of processed surface of nickel-base superalloy as well as preparation method and applications thereof

A nickel-based high-temperature alloy, processed technology, applied in the field of metallographic electrolytic corrosion, can solve the problems such as the inability to observe and measure the thickness of the white layer, and achieve the effects of observation and measurement, good corrosion effect, and simple formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] First put 70ml of hydrochloric acid in the glass container of the electrolytic corrosion instrument, then add 8ml of nitric acid, 12ml of hydrofluoric acid, 5ml of sulfuric acid and 20g of copper sulfate, stir evenly with a glass rod during the addition process, and prepare the etchant.

[0019] Process and polish the workpiece sample of nickel-based superalloy FGH95, the specific steps are:

[0020] 1. Wire-cut the workpiece sample of nickel-based superalloy FGH95 to obtain a cross-sectional sample of the processed surface;

[0021] 2. Use 400#, 800# water sandpaper to polish on the automatic polishing machine in turn;

[0022] 3. Use polishing flannelette to polish on the automatic polishing machine, and add appropriate amount of metallographic polishing agent during the polishing process to improve the polishing effect of the sample.

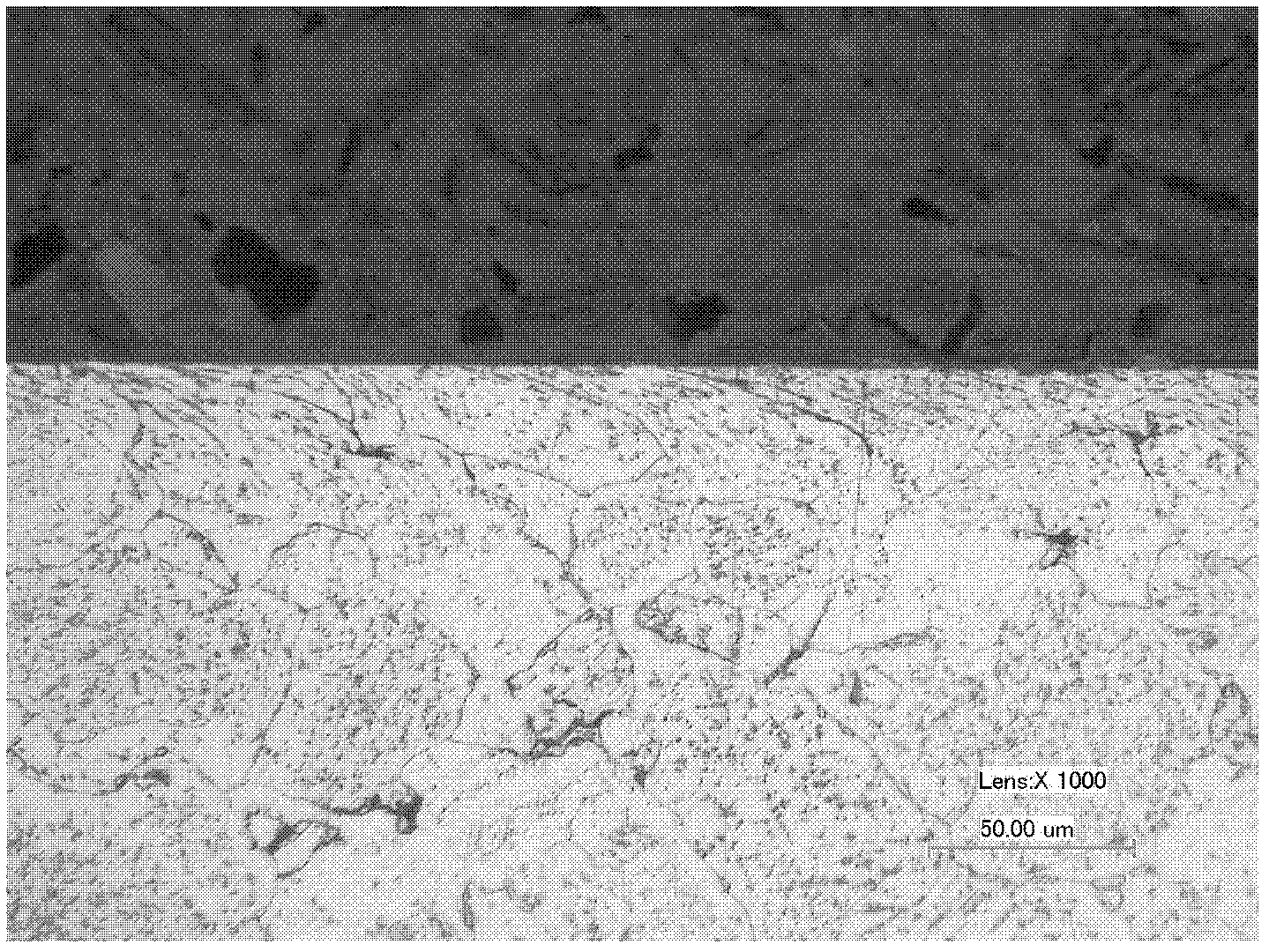

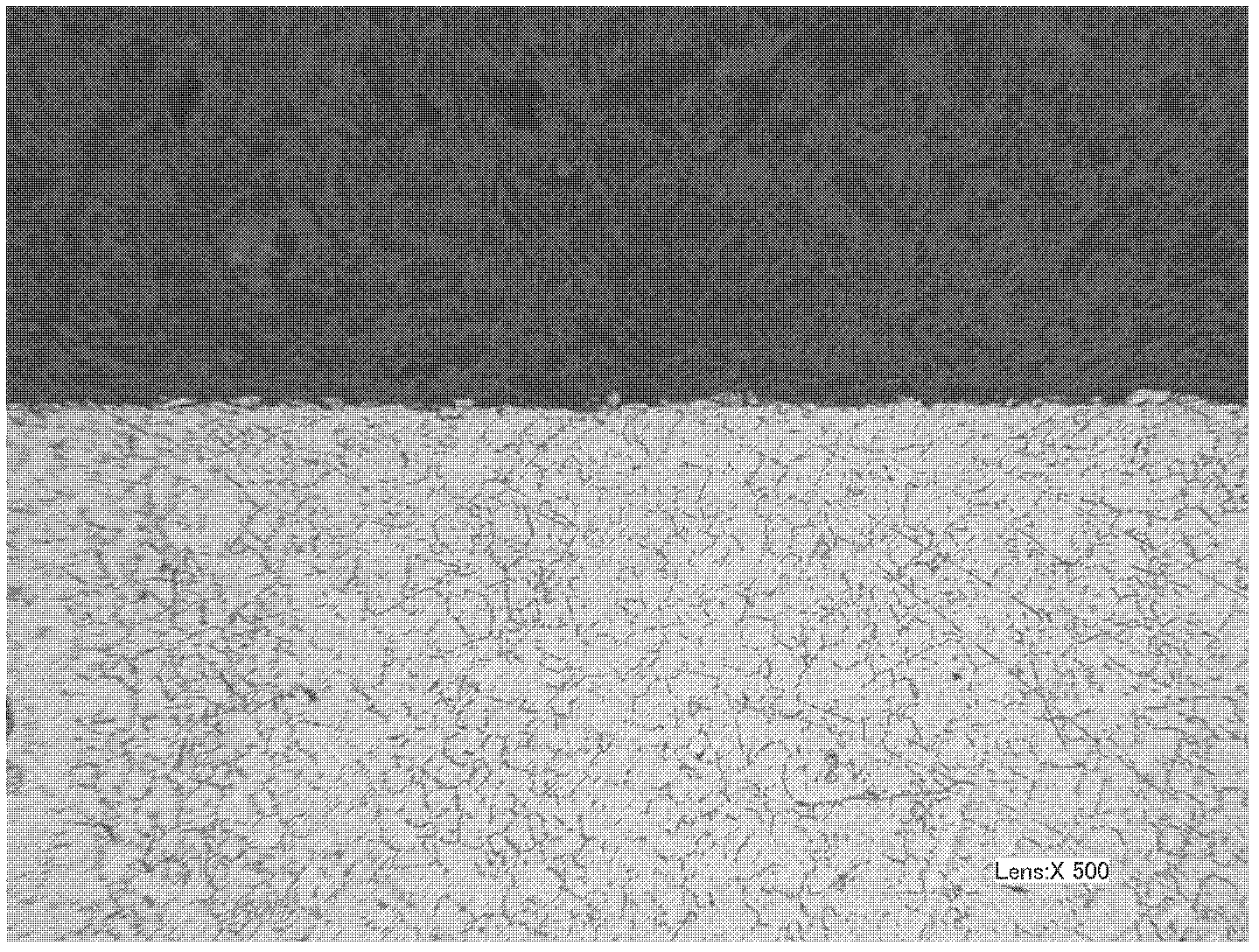

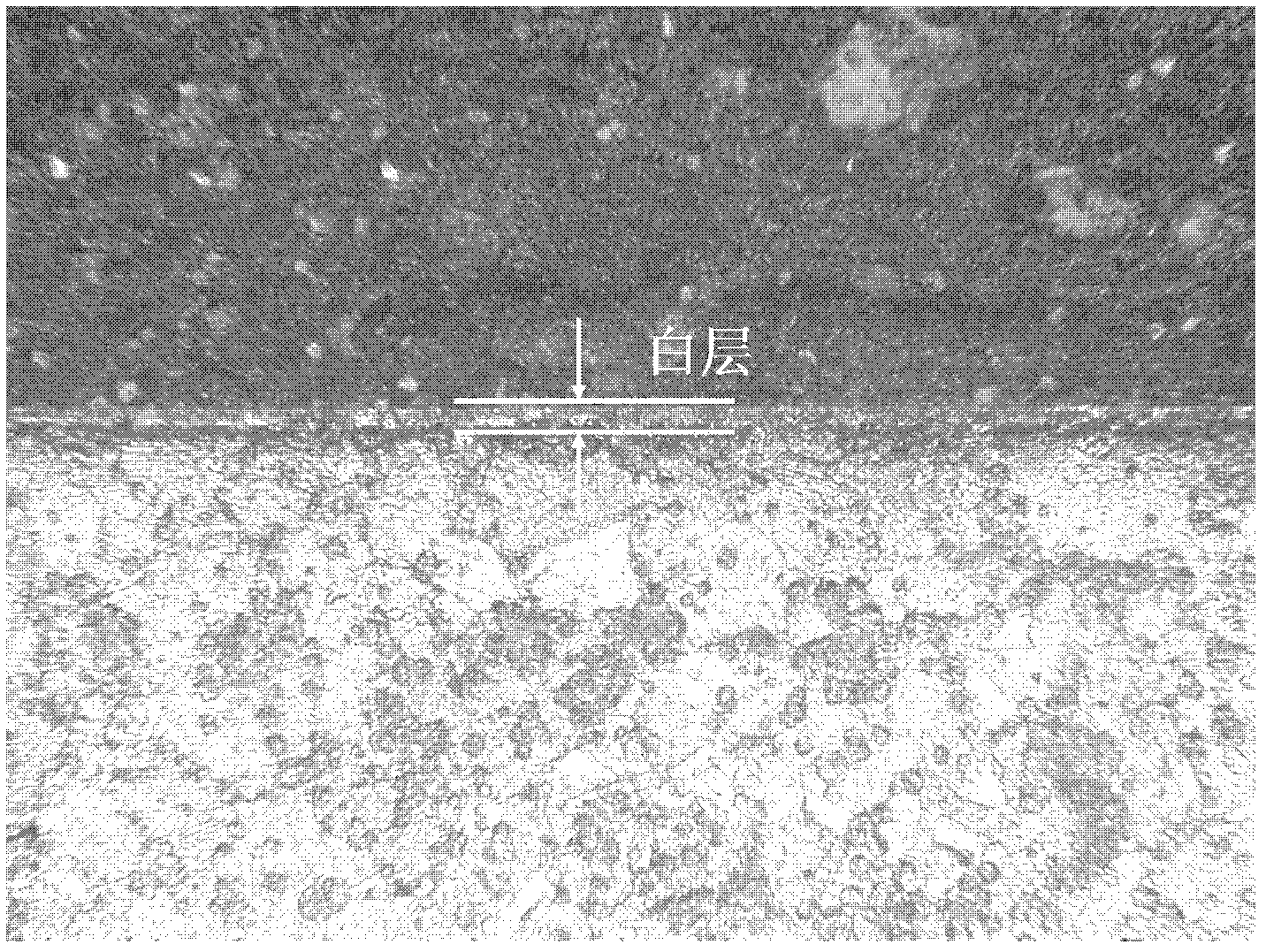

[0023] Adjust the current of the electrolytic corrosion instrument to 0.45A, adjust the voltage to 1.5V, and set the electrolytic co...

Embodiment 2

[0026] First put 73ml of hydrochloric acid in the glass container of the electrolytic corrosion instrument, then add 9ml of nitric acid, 15ml of hydrofluoric acid, 4ml of sulfuric acid, and 15g of copper sulfate. During the addition process, use a glass rod to stir evenly to prepare the etchant.

[0027] Adjust the current of the electrolytic corrosion instrument to 0.47A, adjust the voltage to 1.8V, and set the electrolytic corrosion time to 35 seconds. Connect the nickel-based superalloy GH4169 workpiece sample mechanically polished according to the method of Example 1 to the anode of the electrolytic corrosion instrument, and immerse it together with the stainless steel cathode in the corrosive agent, and pay attention that the sample and the cathode cannot be in contact. Then turn on the power, and the electrolytic corrosion ends after 35 seconds. The sample is taken out from the etchant, rinsed repeatedly with alcohol, and then dried with a hair dryer. Thus, a desired obs...

Embodiment 3

[0030] First put 75ml of hydrochloric acid in the glass container of the electrolytic corrosion instrument, then add 10ml of nitric acid, 10ml of hydrofluoric acid, 3ml of sulfuric acid, and 10g of copper sulfate. During the addition process, use a glass rod to stir evenly to prepare the etchant.

[0031] Adjust the current of the electrolytic corrosion instrument to 0.5A, adjust the voltage to 2V, and set the electrolytic corrosion time to 30 seconds. Connect the nickel-based superalloy GH4169 workpiece sample mechanically polished according to the method of Example 1 to the anode of the electrolytic corrosion instrument, and immerse it together with the stainless steel cathode in the corrosive agent, and pay attention that the sample and the cathode cannot be in contact. Then turn on the power, and the electrolytic corrosion ends after 30 seconds. The sample is taken out from the etchant, rinsed repeatedly with alcohol, and then dried with a hair dryer. Thus, a desired obser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com