Method and system for heating of robots in cold environments

一种机器人、冷环境的技术,应用在控制系统、机械手、电动机控制等方向,能够解决增加设备成本、冷的部件磨损很利害等问题,达到节约时间、快速加热、保护损坏的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

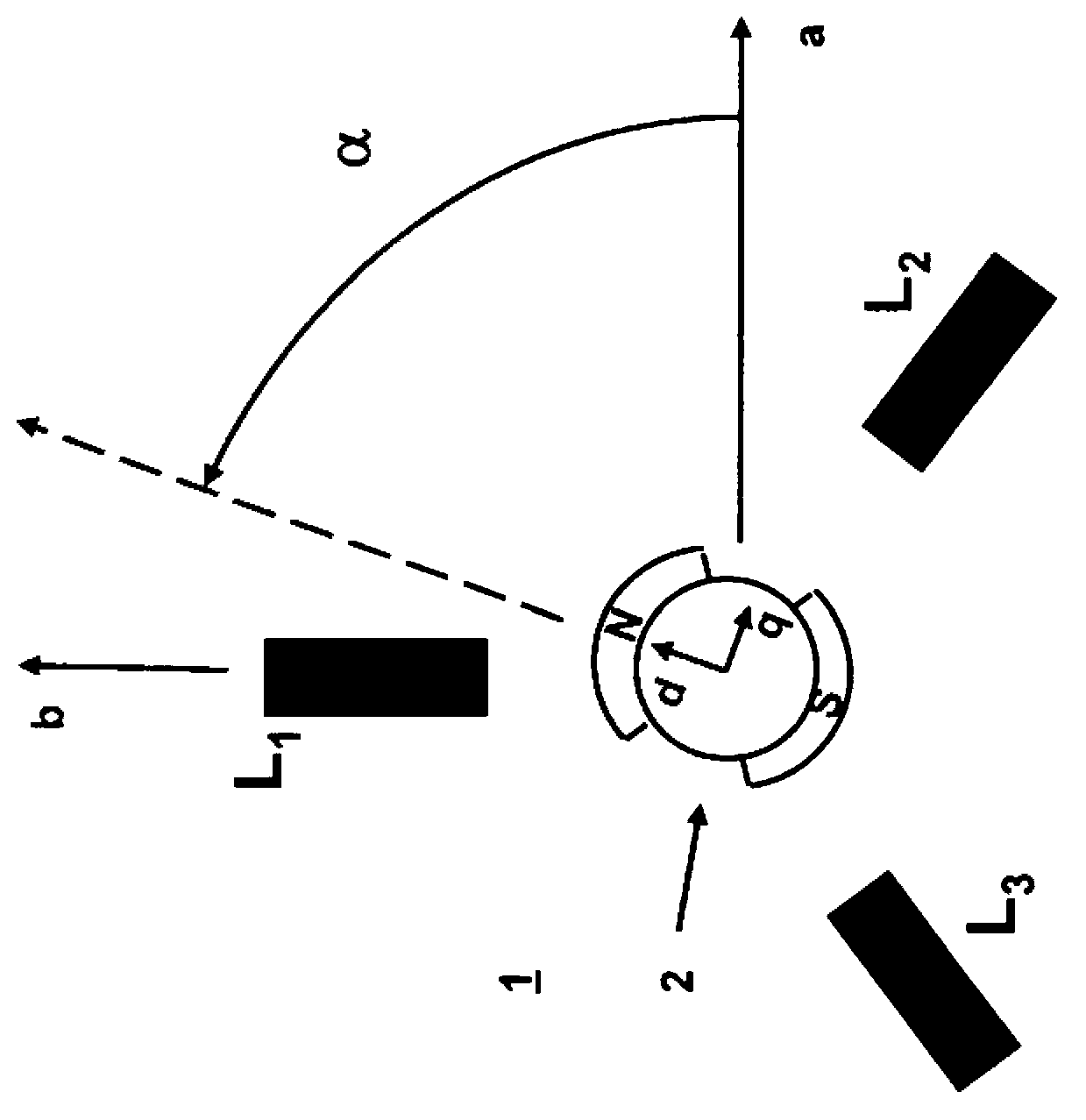

[0014] figure 1 A permanent magnet brushless or synchronous motor 1 is shown with a rotor coordinate system in a stator coordinate system and a rotor position, the permanent magnet brushless or synchronous motor 1 comprising:

[0015] Three motor phases, which include the stator coils L 1 , L 2 , L 3 ,

[0016] · Cartesian stator coordinate system with axis a and axis b, respectively,

[0017] · A rotor 2 with permanent magnets having a north pole N and a south pole S,

[0018] a Cartesian rotor coordinate system with axes d and q, respectively,

[0019] • Rotor position α relative to the stator coordinate system a,b, which means that α corresponds to the angle between the stator axis a and the rotor axis d.

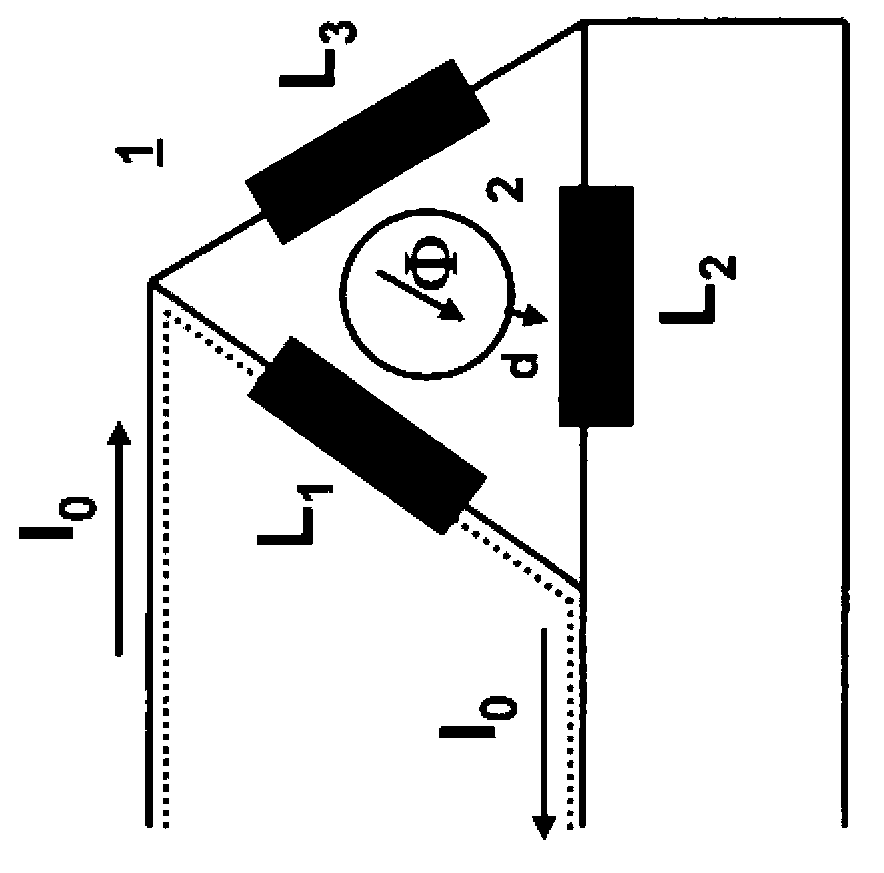

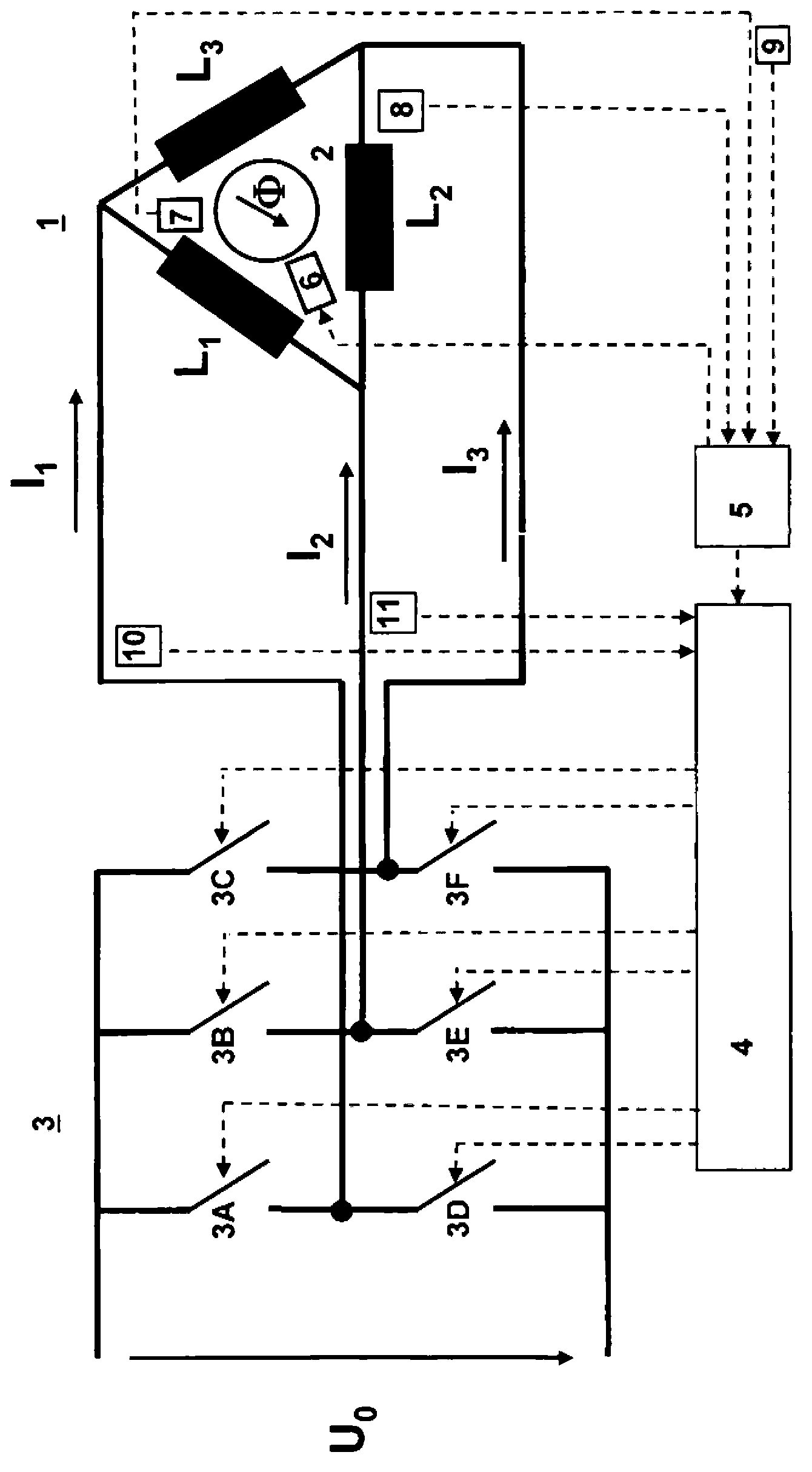

[0020] figure 2 A robot drive system with inverters and motors is shown, comprising:

[0021] · Rotating field inverter 3 with six semiconductor devices 3A, 3B, 3C, 3D, 3E, 3F arranged in relation to the input DC voltage U 0 Three-phase bridge connection and ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com