Structure grain refining method for arc additive manufacturing by adopting aluminum-silicon alloy

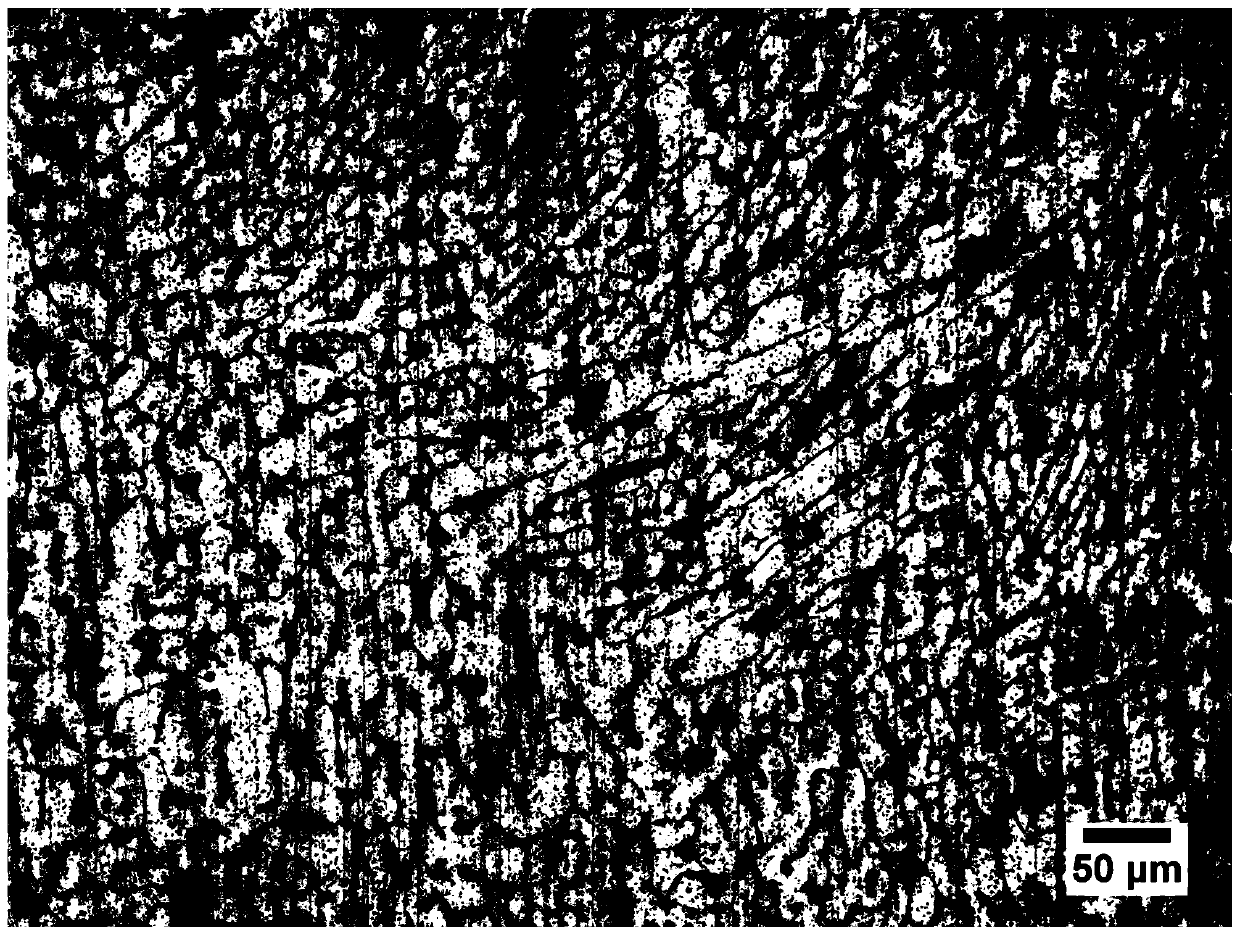

An aluminum-silicon alloy and additive manufacturing technology, which is applied in the direction of manufacturing tools, additive processing, arc welding equipment, etc., can solve the problems of periodic cracks, coarse grains, etc., and achieve moderate weld width, good shape, and eliminate The effect of coarse columnar crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] An embodiment of the present invention provides a microstructure and grain refinement method for arc additive manufacturing using an aluminum-silicon alloy, which includes the following steps:

[0029] Step a, prefabricating the Al-5Ti-1B master alloy into thin slices by wire electric discharge cutting, cleaning with an ultrasonic cleaning machine, cleaning in absolute ethanol and drying;

[0030] Step b. Place the sheet between two adjacent layers of Al-Si alloy, and the thickness of each Al-Si alloy layer is 2mm, under the protective atmosphere of argon gas, and the flow rate of argon gas is 15L / min , using the arc additive manufacturing method for aluminum-silicon alloy arc additive manufacturing, wherein the quality of the thin slice placed on each layer is 1.14% of the mass of the upper aluminum-silicon alloy, the length of the thin slice is the same as the length of the aluminum-silicon alloy layer, and the arc additive The wire feeding speed of the manufacturing ...

Embodiment 2

[0032] An embodiment of the present invention provides a microstructure and grain refinement method for arc additive manufacturing using an aluminum-silicon alloy, which includes the following steps:

[0033] Step a, prefabricating the Al-5Ti-1B master alloy into thin slices by wire electric discharge cutting, cleaning with an ultrasonic cleaning machine, cleaning in absolute ethanol and drying;

[0034] Step b. Place the sheet between two adjacent layers of Al-Si alloy, and the thickness of each layer of Al-Si alloy is 0.3mm, under the protective atmosphere of argon gas, and the flow rate of argon gas is 18L / min, using the arc additive manufacturing method to carry out arc additive manufacturing of aluminum-silicon alloy, wherein the mass of the thin slice placed on each layer is 3% of the mass of the upper layer of aluminum-silicon alloy, and the length of the thin slice is the same as the length of the aluminum-silicon alloy layer. The wire feeding speed of the material ma...

Embodiment 3

[0036] An embodiment of the present invention provides a microstructure and grain refinement method for arc additive manufacturing using an aluminum-silicon alloy, which includes the following steps:

[0037] Step a, prefabricating the Al-5Ti-1B master alloy into thin slices by wire electric discharge cutting, cleaning with an ultrasonic cleaning machine, cleaning in absolute ethanol and drying;

[0038] Step b. Place the sheet between two adjacent layers of Al-Si alloy, and the thickness of each layer of Al-Si alloy is 2.5mm, under the protective atmosphere of argon gas, and the flow rate of argon gas is 20L / min, using the arc additive manufacturing method to carry out arc additive manufacturing of aluminum-silicon alloy, wherein the mass of the thin slice placed on each layer is 5% of the mass of the upper layer of aluminum-silicon alloy, the length of the thin slice is the same as the length of the aluminum-silicon alloy layer, and the arc increases The wire feeding speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com