Dimethyl oxalate production device

A technology of dimethyl oxalate and production equipment, which is applied in the direction of carbon monoxide or formate reaction preparation, organic chemistry, etc., and can solve problems such as energy waste and multiple condensates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

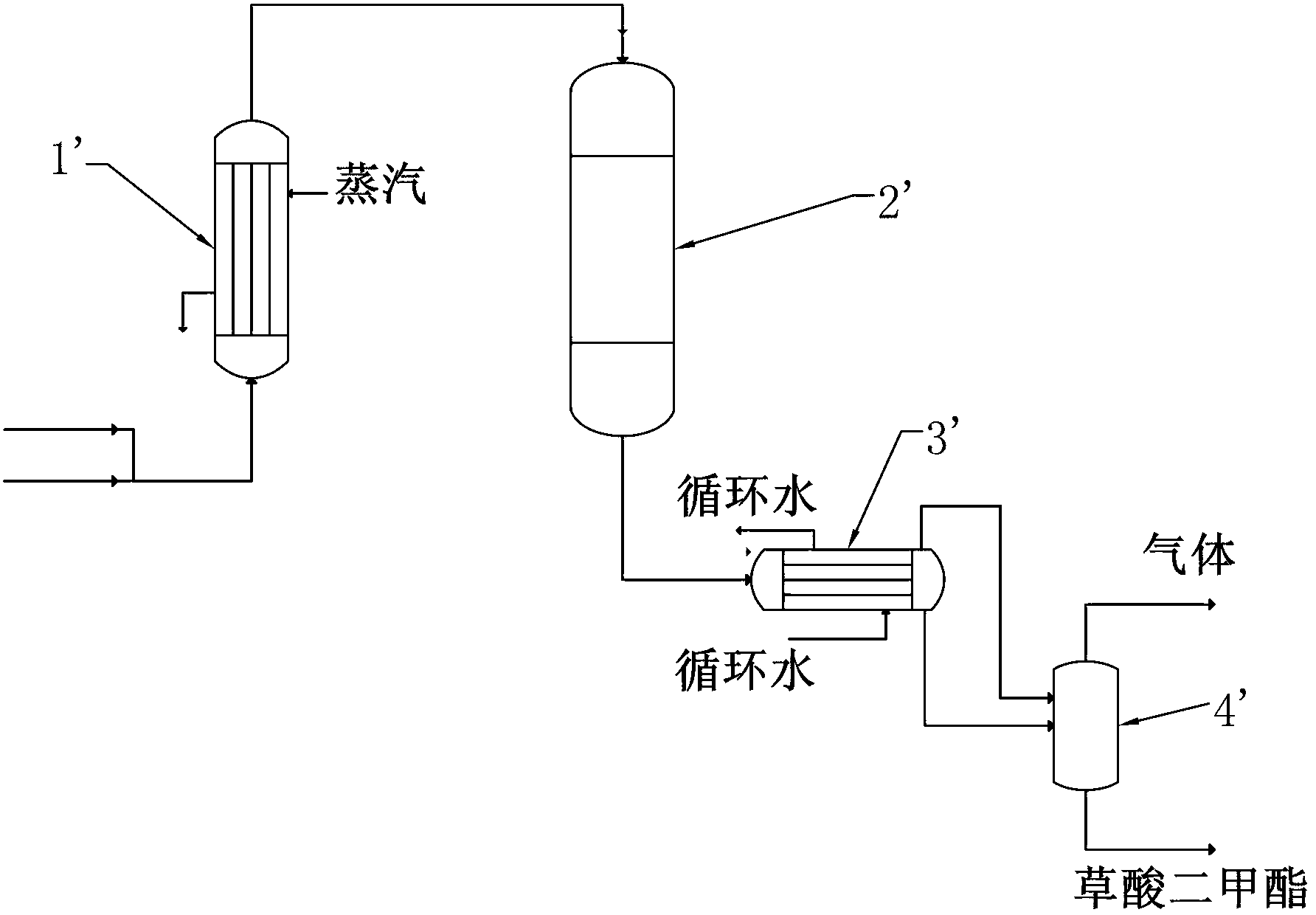

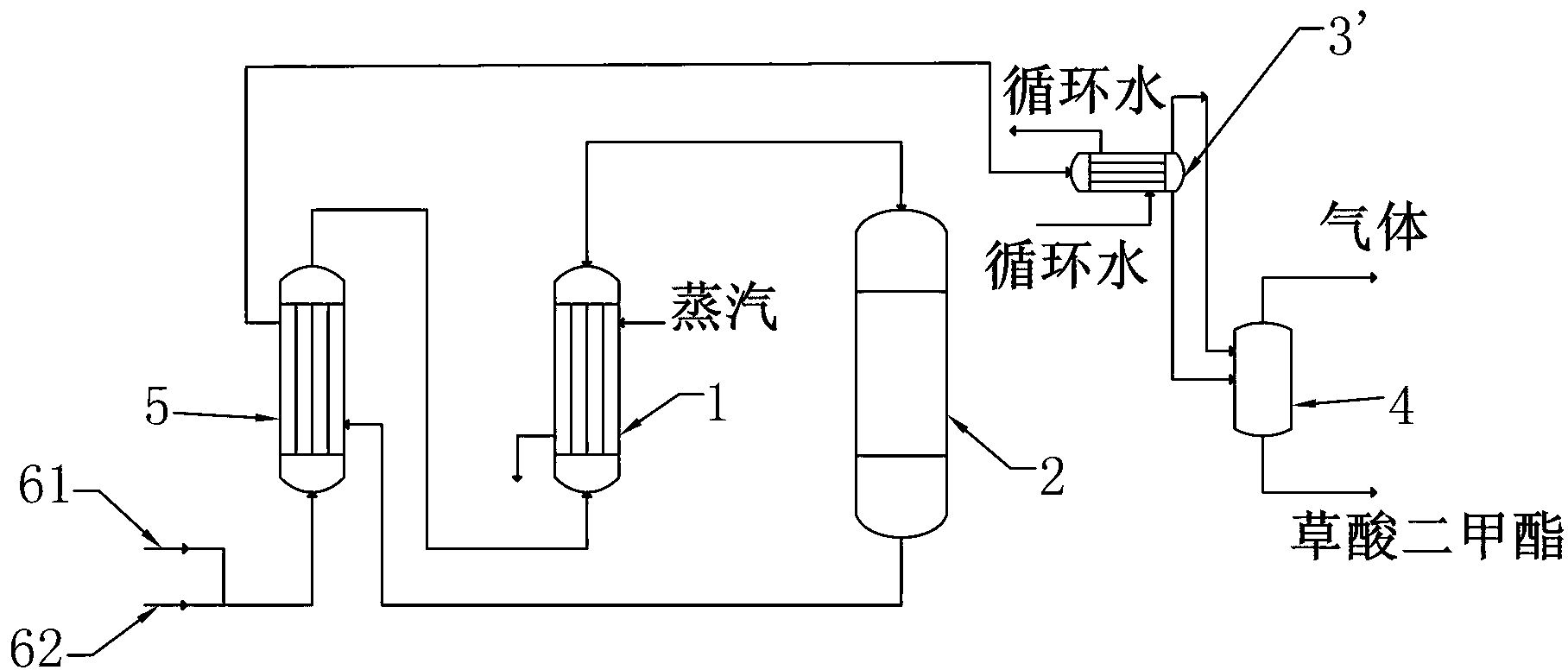

[0015] Such as figure 2 Shown, the dimethyl oxalate production equipment of the present invention comprises heater 1, carbonylation reactor 2, condenser 3, gas-liquid separator 4, also comprises preheater 5, wherein the material inlet to be heated of preheater 5 and The methyl nitrite delivery pipeline 61 communicates with the CO delivery pipeline 62, the outlet of the material to be heated of the preheater 5 is connected with the inlet of the material to be heated of the heater 1, and the reaction between the outlet of the material to be heated of the heater 1 and the carbonylation reactor 2 The material inlet is connected, the reaction material outlet of the carbonylation reactor 2 is connected with the heating medium inlet of the preheater 5, the heating medium outlet of the preheater 5 is connected with the condensed material inlet of the condenser 3, and the condensed material gas outlet of the condenser 3 The outlet of the condensed material liquid is respectively conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com