Pile-up welding method of turbine low pressure heater pipe plate and shell, water chamber junction

A low-pressure heater and steam turbine technology, applied in heat treatment furnaces, heat treatment equipment, machines/engines, etc., can solve problems such as poor heat treatment effect, low production efficiency, and difficult processing, and achieve easy welding operations, improved production efficiency, and reduced The effect of welding process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

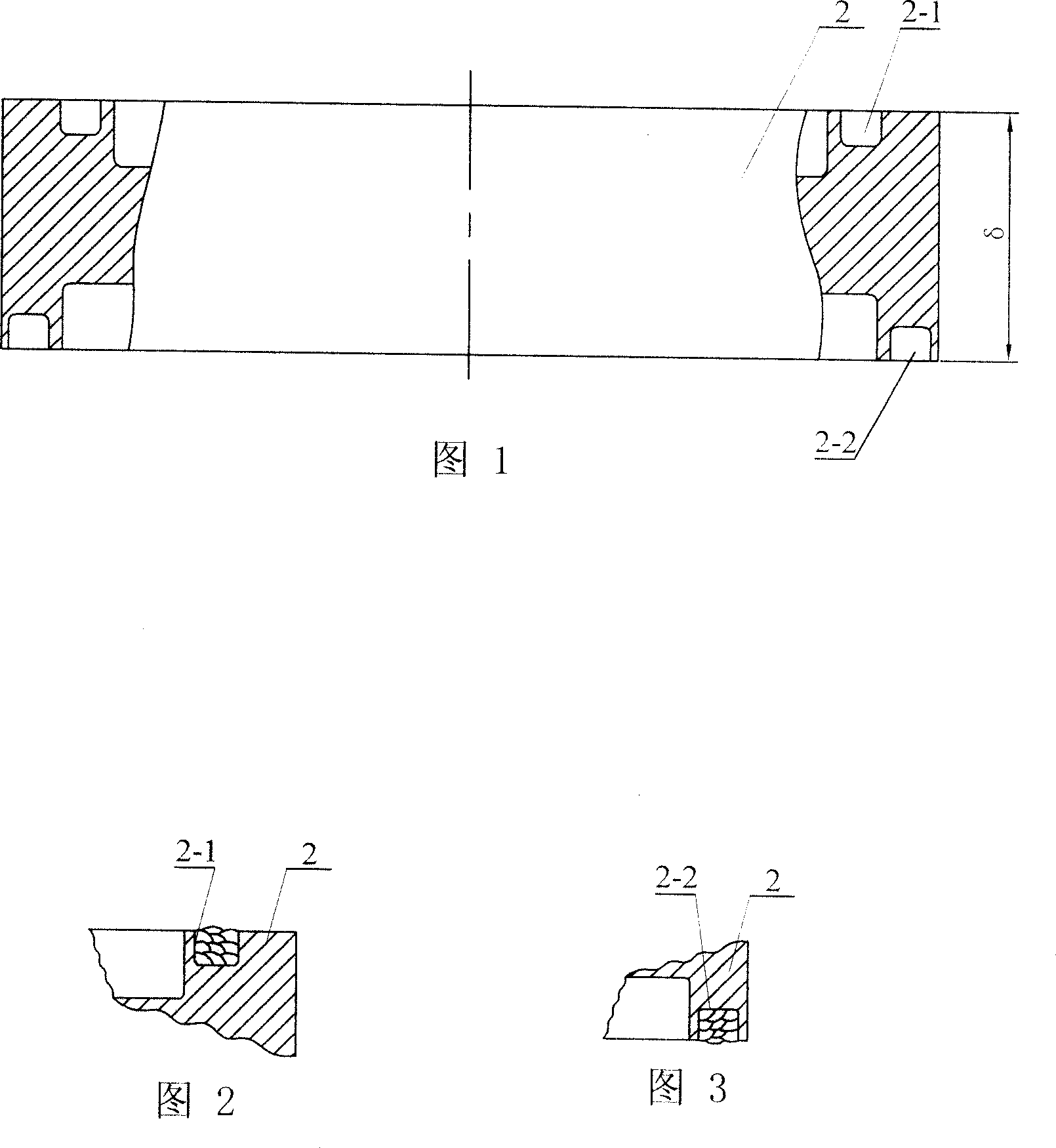

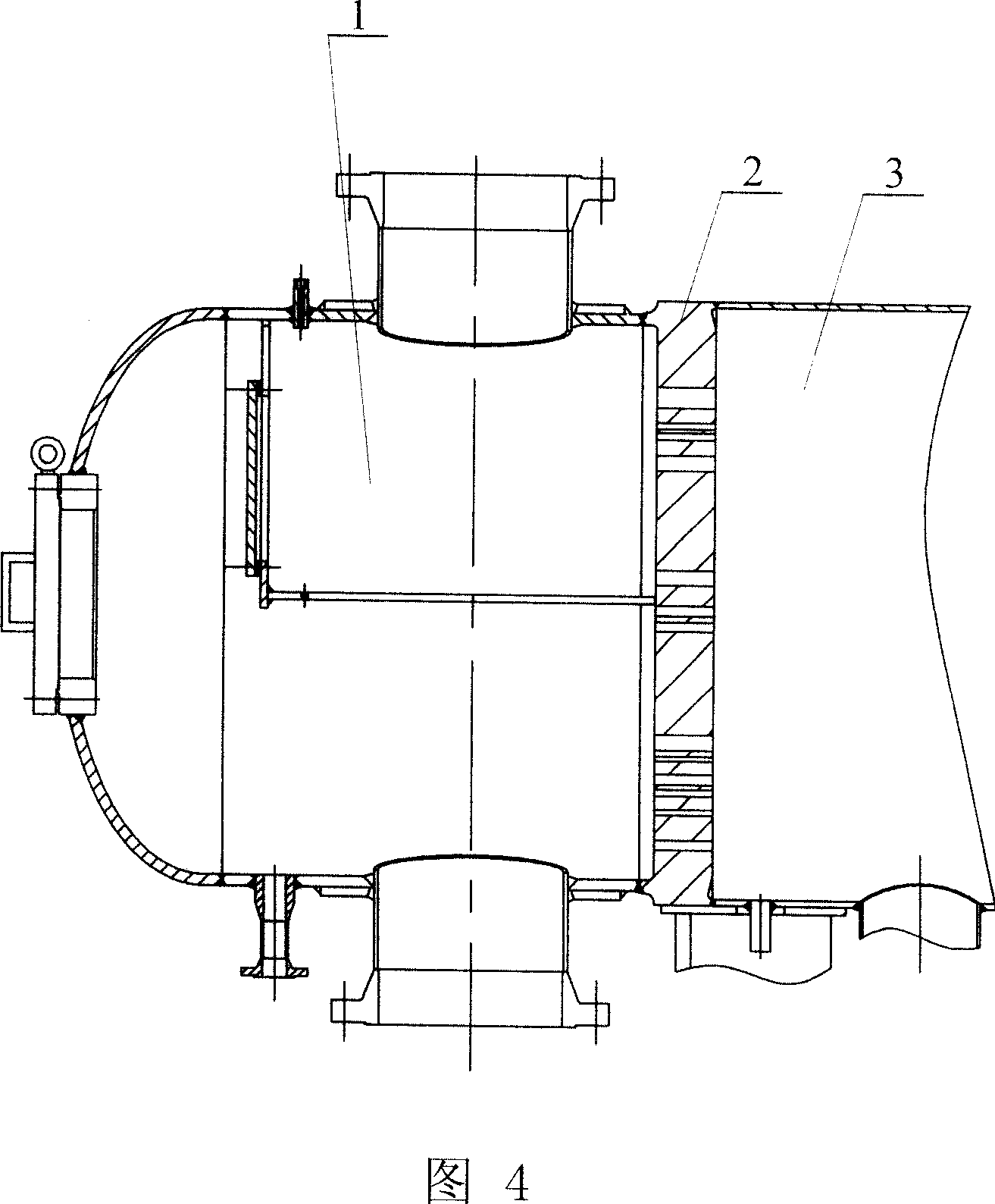

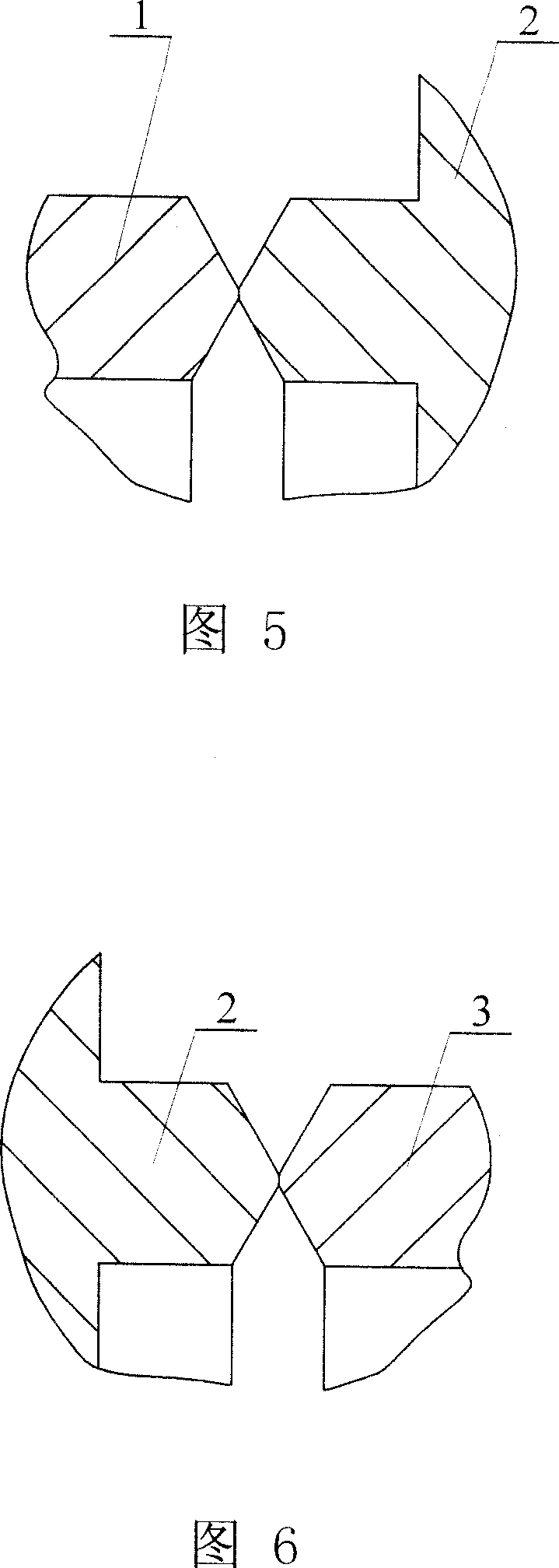

[0007] Specific embodiment one: this embodiment is described in conjunction with Fig. 1~Fig. 6, and this embodiment is completed by the following steps: a, steam turbine low-pressure heater tube plate 2 adopts the 20MnMo or 16MnR alloy steel forging that thickness δ is 90~240mm, through rough After processing, a first annular groove 2-1 is processed on one side of the connection between the tube plate 2 of the steam turbine low-pressure heater and the water chamber 1, and a first annular groove 2-1 is processed on the other side of the connection between the tube plate 2 of the low-pressure heater of the steam turbine and the casing 3. A second annular groove 2-2 is processed on the side surface, and the depth h1 of the first annular groove 2-1 and the depth h2 of the second annular groove 2-2 are both 20 to 30 mm; b, the steam turbine low-pressure heater The tube sheet 2 is preheated to 150-200°C as a whole, and then carbon steel is surfacing layer by layer in the first annula...

specific Embodiment approach 2

[0008] Specific embodiment two: this embodiment is described in conjunction with Fig. 1, the difference between this embodiment and specific embodiment one is: in step a of this embodiment, the steam turbine low-pressure heater tube plate 2 adopts 20MnMo alloy steel whose thickness δ is 100mm For the forging, the depth h1 of the first annular groove 2-1 and the depth h2 of the second annular groove 2-2 are both 20-22mm. The depth of the annular groove is very important to the welding quality. If it is too deep, the amount of welding will increase and it will easily cause deformation; if it is too shallow, after the tube plate 2 of the steam turbine low-pressure heater is finished, the transition layer is too thin to achieve the purpose of heat insulation. Considering the above factors, it is determined that the depth of the two annular grooves is within the range of 20-22mm, which can ensure the welding quality.

specific Embodiment approach 3

[0009] Specific embodiment three: This embodiment is described in conjunction with Fig. 1 and Fig. 4, and the difference between this embodiment and specific embodiment one is: in step a of this embodiment, the steam turbine low-pressure heater tube plate 2 adopts a tube plate with a thickness δ of 200mm. For the 20MnMo alloy steel forging, the depth h1 of the first annular groove 2-1 and the depth h2 of the second annular groove 2-2 are both 28-30mm. The depth of the two annular grooves is selected within the above range, which can ensure the welding quality of the tube plate 2 of the low-pressure heater of the steam turbine, the casing 3 and the water chamber 1 .

[0010] Embodiment 4: This embodiment is described in conjunction with Fig. 1 and Fig. 4. The difference between this embodiment and Embodiment 1 is that in step a of this embodiment, the steam turbine low-pressure heater tube plate 2 adopts a tube plate with a thickness δ of 92mm. For a 16MnR alloy steel forging, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com