Engine-cooling system

An engine cooling and engine technology, applied in the direction of engine cooling, engine components, machines/engines, etc., can solve problems such as engine temperature drop, avoid energy waste, and solve adverse effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

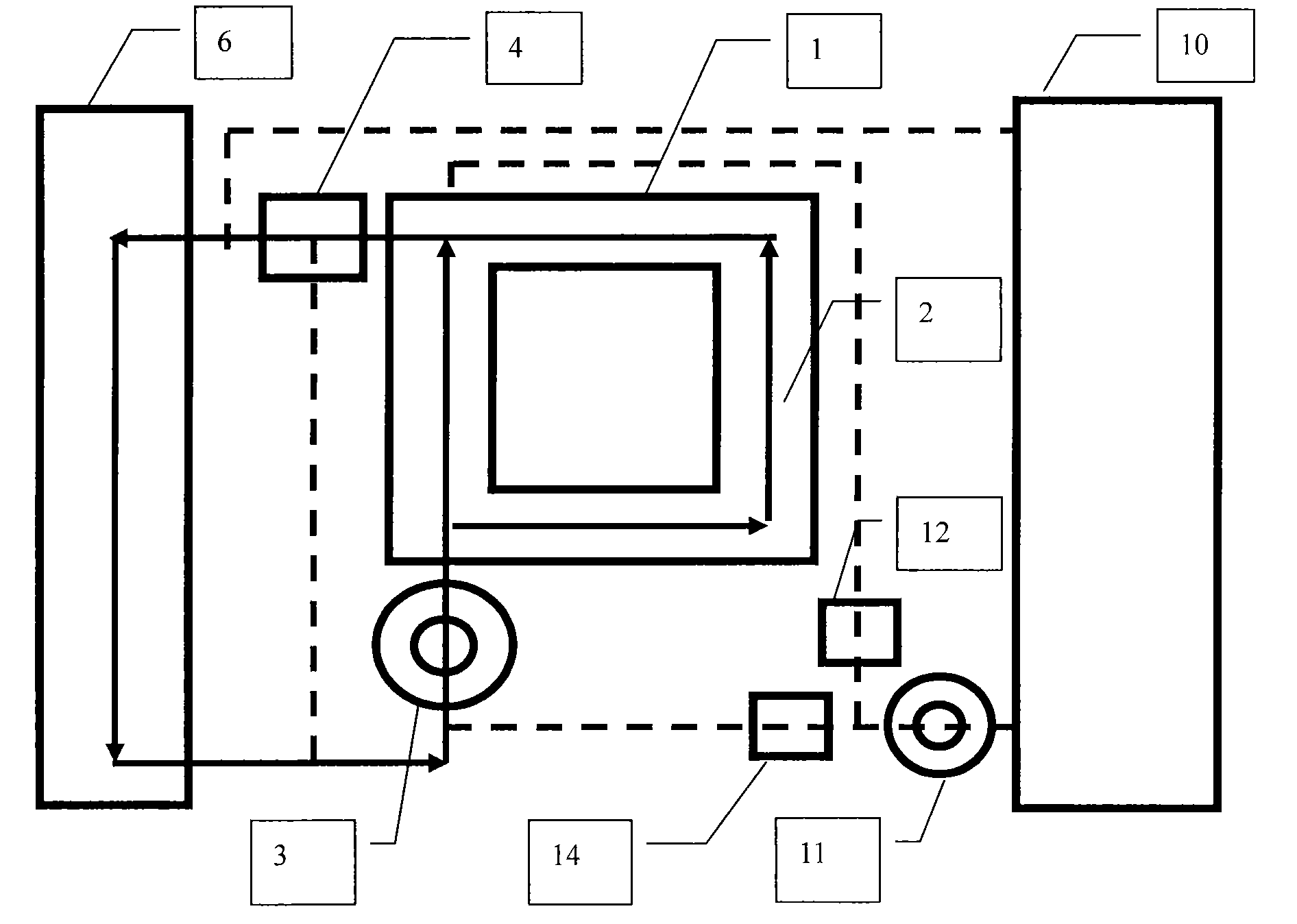

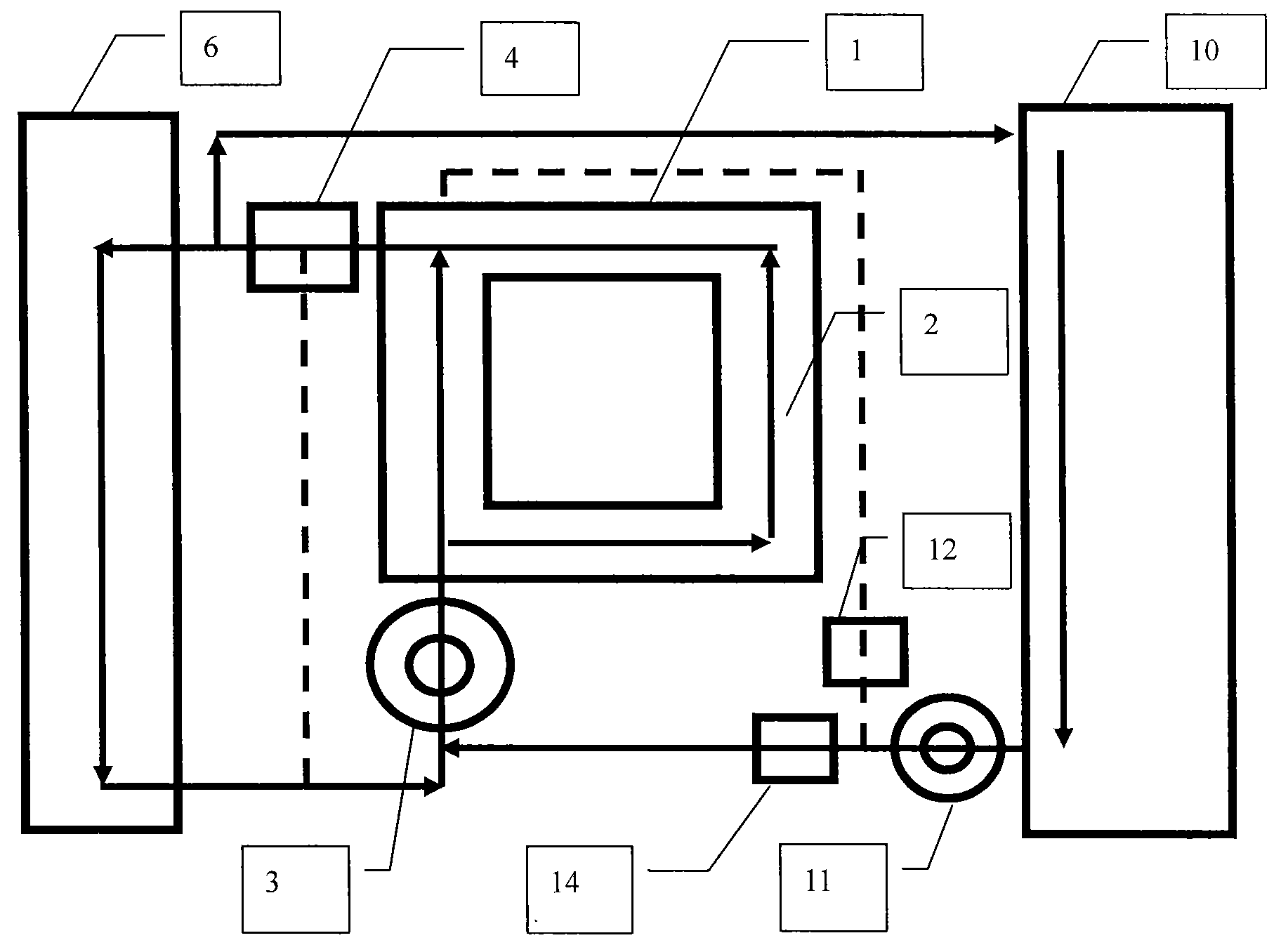

[0034] Two preferred embodiments of the invention will now be described with reference to the accompanying drawings.

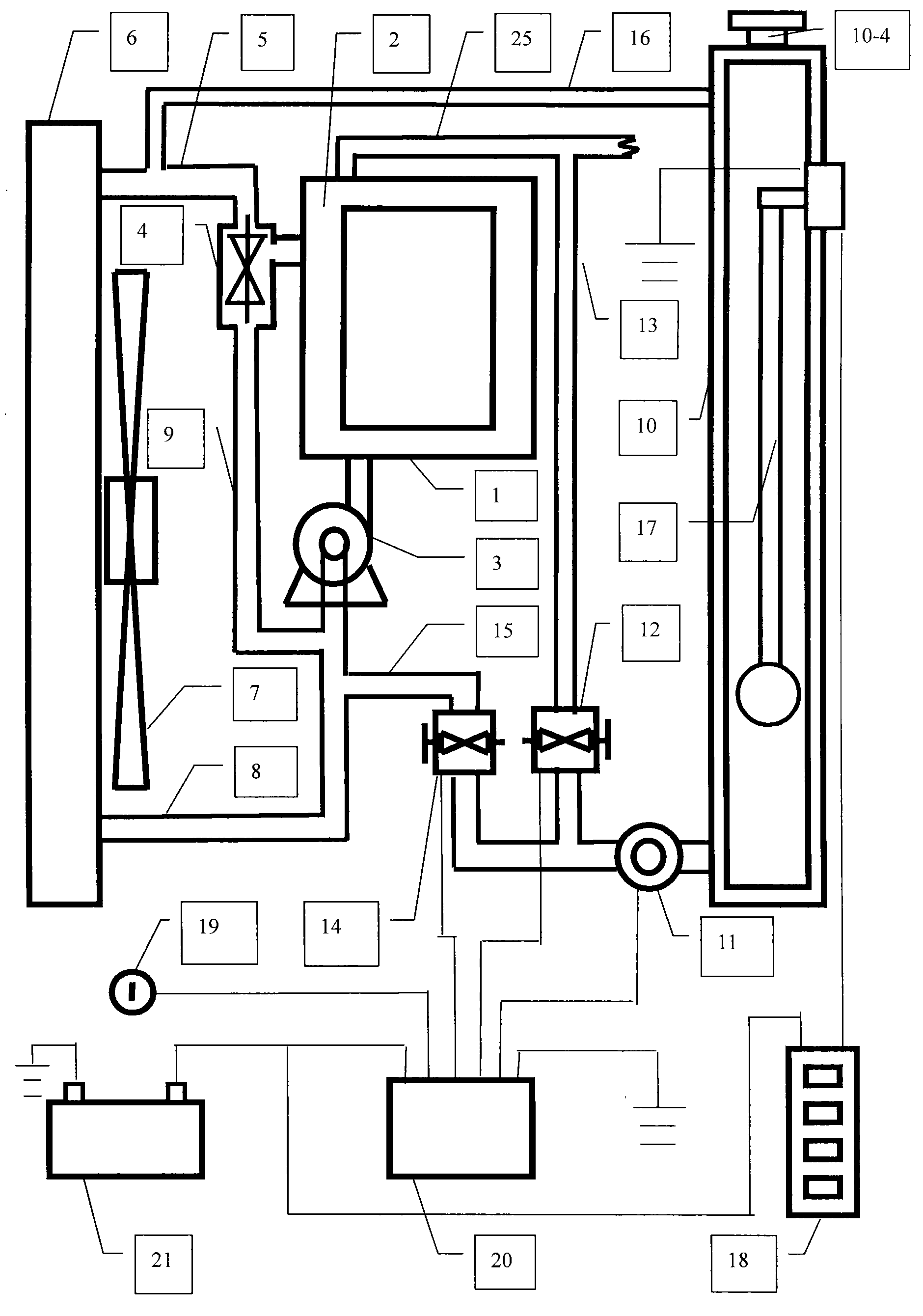

[0035] exist figure 1 In the shown embodiment 1, water jacket 2, water pump 3, thermostat 4, upper outlet pipe 5, cooling water tank 6, fan 7, lower water inlet pipe 8, bypass pipe 9 constitute the cooling branch of cooling system; Hot water tank 10, two-way electric water pump 11, suction solenoid valve 14, water injection solenoid valve 12, water suction pipe 15, water injection pipe 13, return water ventilation pipe 16, water volume display sensor 17, water volume display 18, and central controller 20 form a cooling system thermal insulation branch. Wherein, the pumping pipe 15 in the heat preservation and heat storage branch communicates with the lowest point of the lower water inlet pipe 8 in the heat dissipation branch, and the return water ventilation pipe 16 in the heat preservation and heat storage branch is connected with the upper outlet pipe 5 in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com