Air source heat pump spray defrosting device based on superhydrophobic finned tube heat exchanger

A technology of finned tube heat exchanger and air source heat pump, which is applied in the operation mode of the machine, the combination of heating and cooling, lighting and heating equipment, etc., can solve the problem that the defrosting efficiency is difficult to improve, the defrosting speed is slow, and the heat consumption is large. And time and other issues, to achieve the effect of not affecting thermal comfort, low heat consumption for defrosting, and improving heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

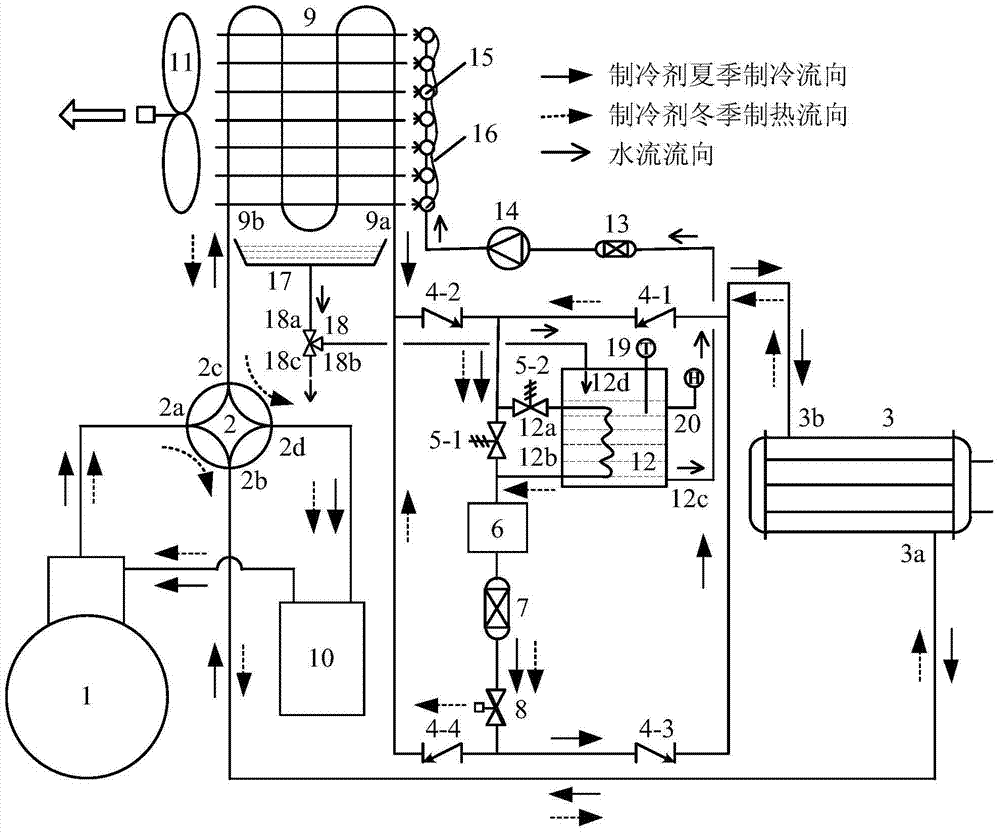

[0028] An air source heat pump spray defrosting device based on a superhydrophobic finned tube heat exchanger includes a refrigerant circuit, a hot water circuit and an air circuit.

[0029] In the refrigerant circuit, the output end of the compressor 1 is connected to the first input end 2a of the four-way valve, the first output end 2b of the four-way valve is connected to the input end 3a of the first heat exchanger, and the output end 3b of the first heat exchanger is divided into Two ways, one way is connected with the inlet of the first one-way valve 4-1, the other way is connected with the outlet of the third one-way valve 4-3, the outlet of the first one-way valve 4-1 is divided into three ways, one way is connected with the second one-way valve The outlet of the one-way valve 4-2 is connected, one way is connected to the input end of the liquid reservoir 6 through the first electromagnetic valve 5-1, and the other way is connected to the first input end 12a of the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com