Wire-and-tube evaporator

An evaporator and wire-tube type technology, applied in the field of wire-tube type evaporators, can solve the problems of technical design, i.e. difficulty in structural design, influence on the working efficiency of a refrigeration device, and defrosting dependent on the external environment, etc. Short cream time, enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

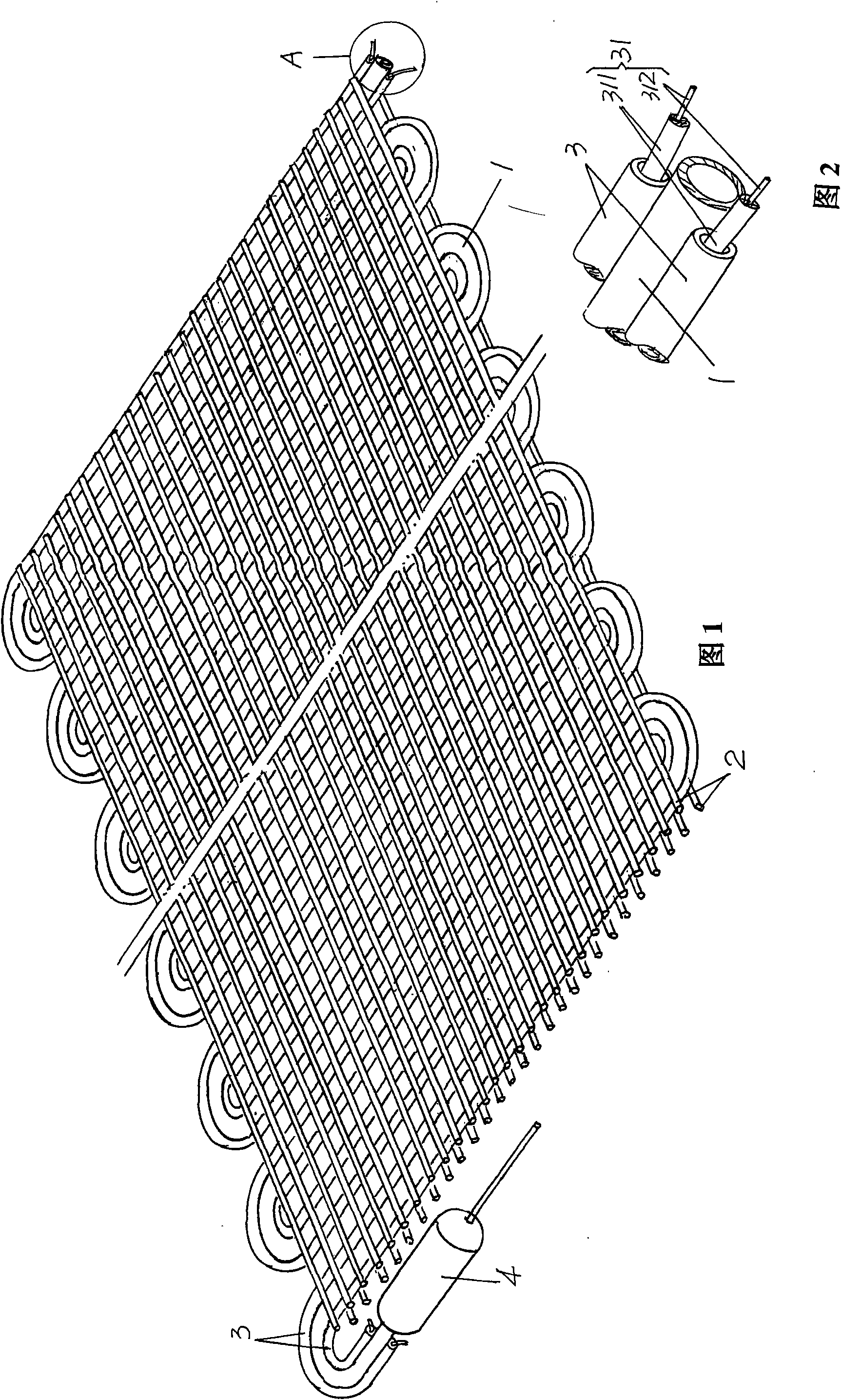

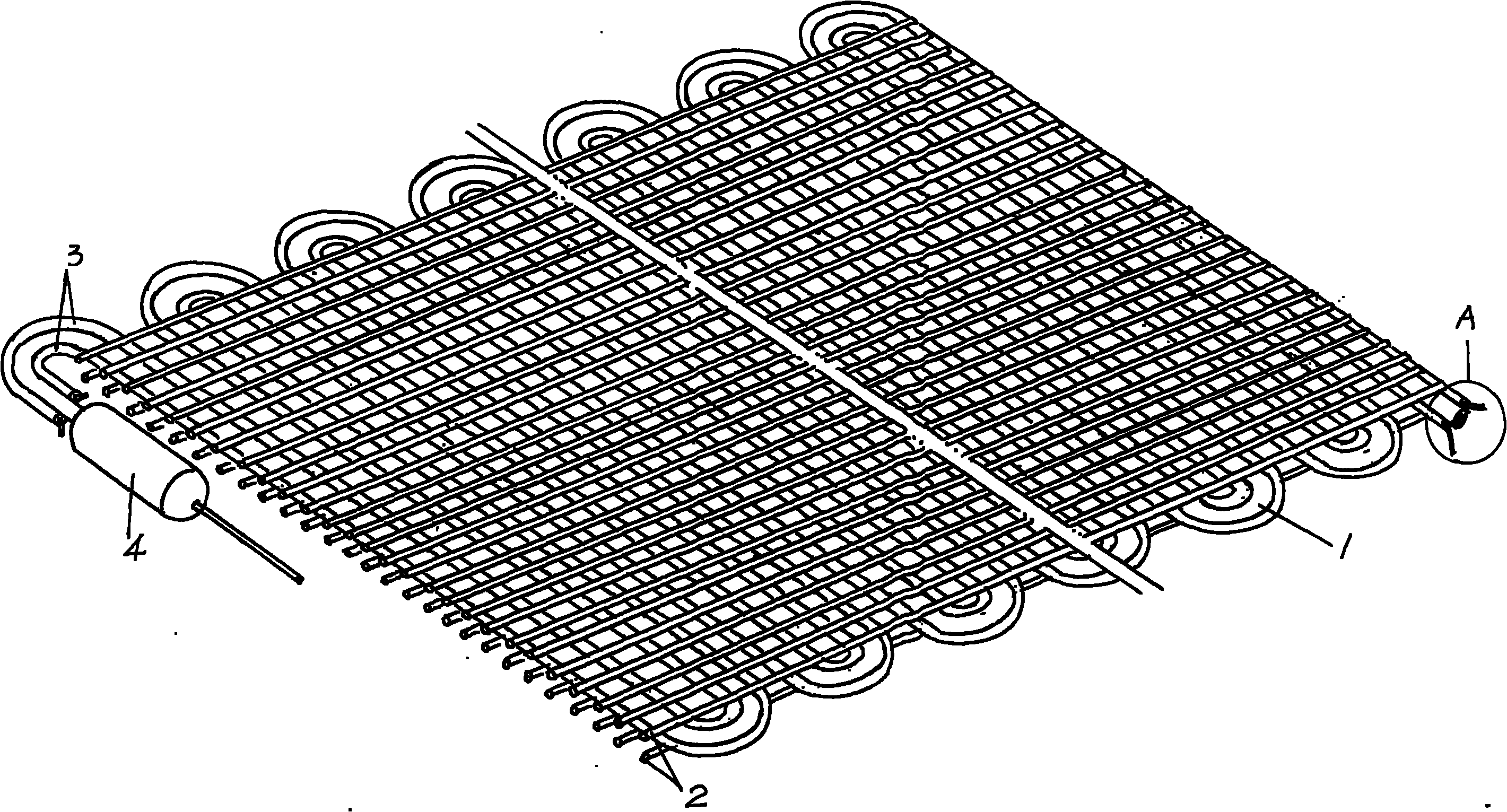

[0015] please see figure 1 and figure 2 , the given evaporating tube 1 is meandering and serpentine. In the present embodiment, the number of the evaporating tube 1’s twists and turns does not need to be limited, because it can be shown according to refrigeration devices such as refrigerators, refrigerated refrigerators, etc. Depending on the size of the cabinet or freezer (increase or decrease), the size of each zigzag is the same. The evaporating tube 1 is preferably an iron tube with a copper-plated layer on the surface, that is, a copper layer is plated on the surface of the iron tube. In this embodiment, there are two wires 2, each of which is fixed to the upper side and the lower side of the evaporating tube 1 by spot welding. More specifically, with the current figure 1 The position state shown is an example, the surface of the upward side of the evaporation tube 1 is fixed (fixed by spot welding) with a group of metal wires 2 in a grid state, and the surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com