Horizontal-tube carbon intermediate continuous thermal treatment device

A heat treatment device and intermediate technology, applied in lighting and heating equipment, furnace cooling, furnace type, etc., can solve the problems of multi-pollution, long production cycle, energy waste, etc., achieve a high degree of automation, and overcome the effect of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

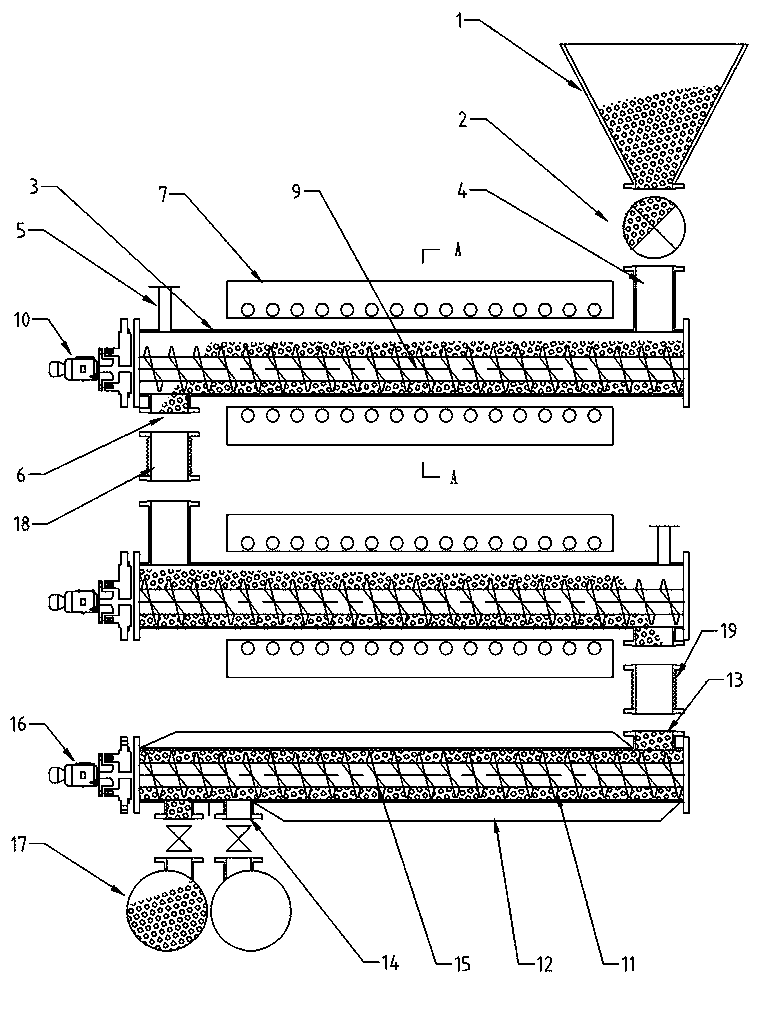

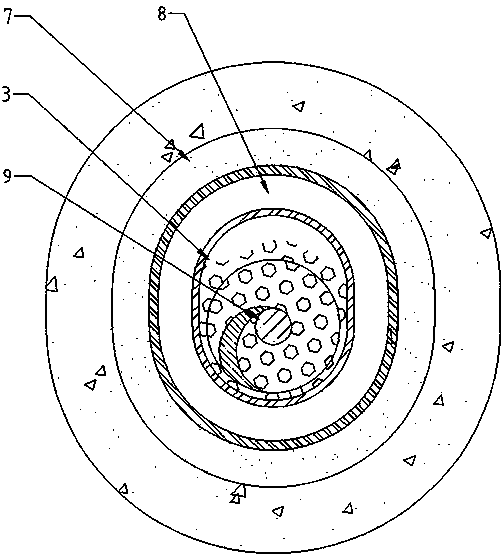

[0023] Reference attached figure 1 And attached figure 2, a horizontal tube type continuous heat treatment device for carbonaceous intermediates, including sequentially connected feeding system, heating section, cooling section, tail gas system and discharging system; the feeding system is a conical silo with a funnel opening at the bottom ( 1) and feeder (2); the feeding system, heating section, cooling section and discharging system are all connected through the sensor circuit and the measurement and control system; The first section of the two sections of horizontal tubes is the preheating part, and the second section of the horizontal tube is the main heating part; the above two sections of horizontal tubes are basically the same in structure, both of which are long cylinders with caps on both ends ( 3), the elongated cylinder (3) is made of heat-resistant heat-conducting material, with a feed inlet (4) above one end and a discharge outlet (6) below the other end; on the...

Embodiment 2

[0032] A horizontal tube type continuous heat treatment device for carbonaceous intermediates, including sequentially connected feeding system, heating section, cooling section, tail gas system and discharging system; the feeding system is a conical silo with a funnel opening at the bottom (1 ) and feeder (2); the feeding system, heating section, cooling section and discharging system are all connected through the sensing circuit and the measurement and control system; Connected in series; the first section of the three-section horizontal tube is the preheating part, and the second and third horizontal tubes are the main heating part; the structure of each of the above-mentioned horizontal tubes is basically the same, all of which are long and closed with covers at both ends. Cylinder (3), the elongated cylinder (3) is made of high-temperature-resistant heat-conducting material, with a feed inlet (4) above one end and a discharge outlet (6) below the other end; on the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com